PROMO ESTATE: Risparmia 1700€ sulla Supercombinata SC1 + Kit Riduzione per alesatura Ø 32-70 mm!

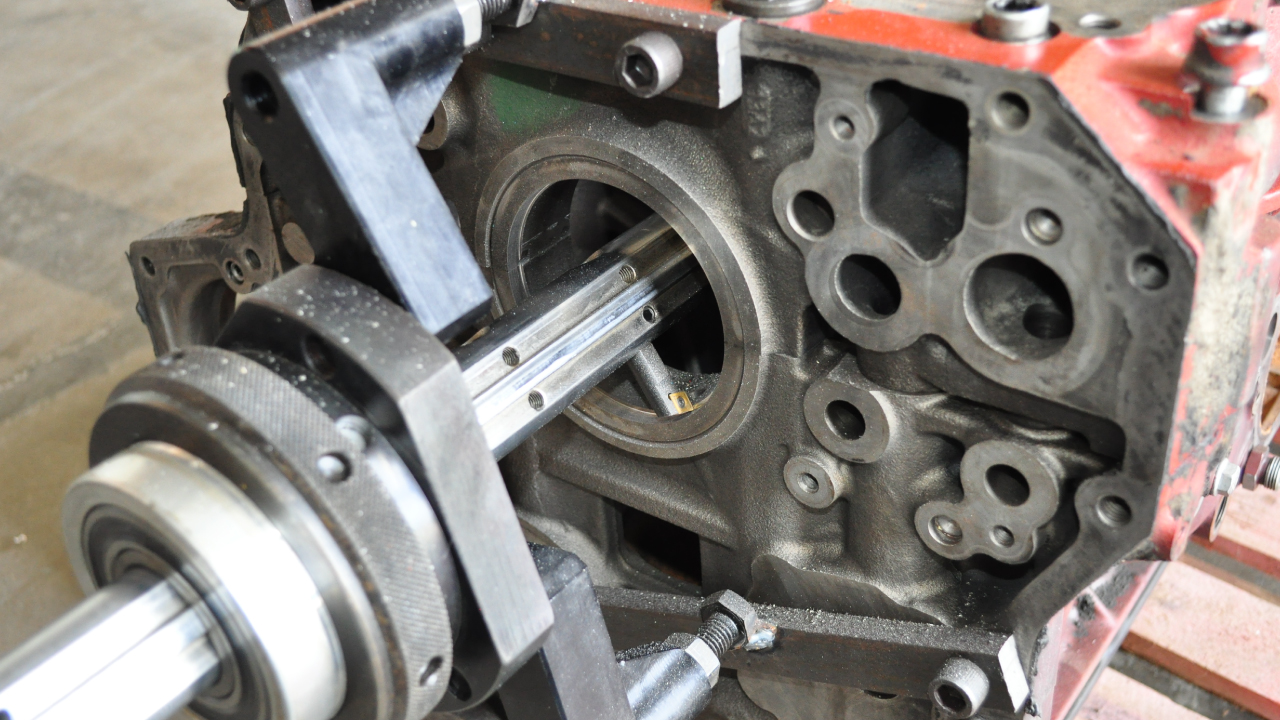

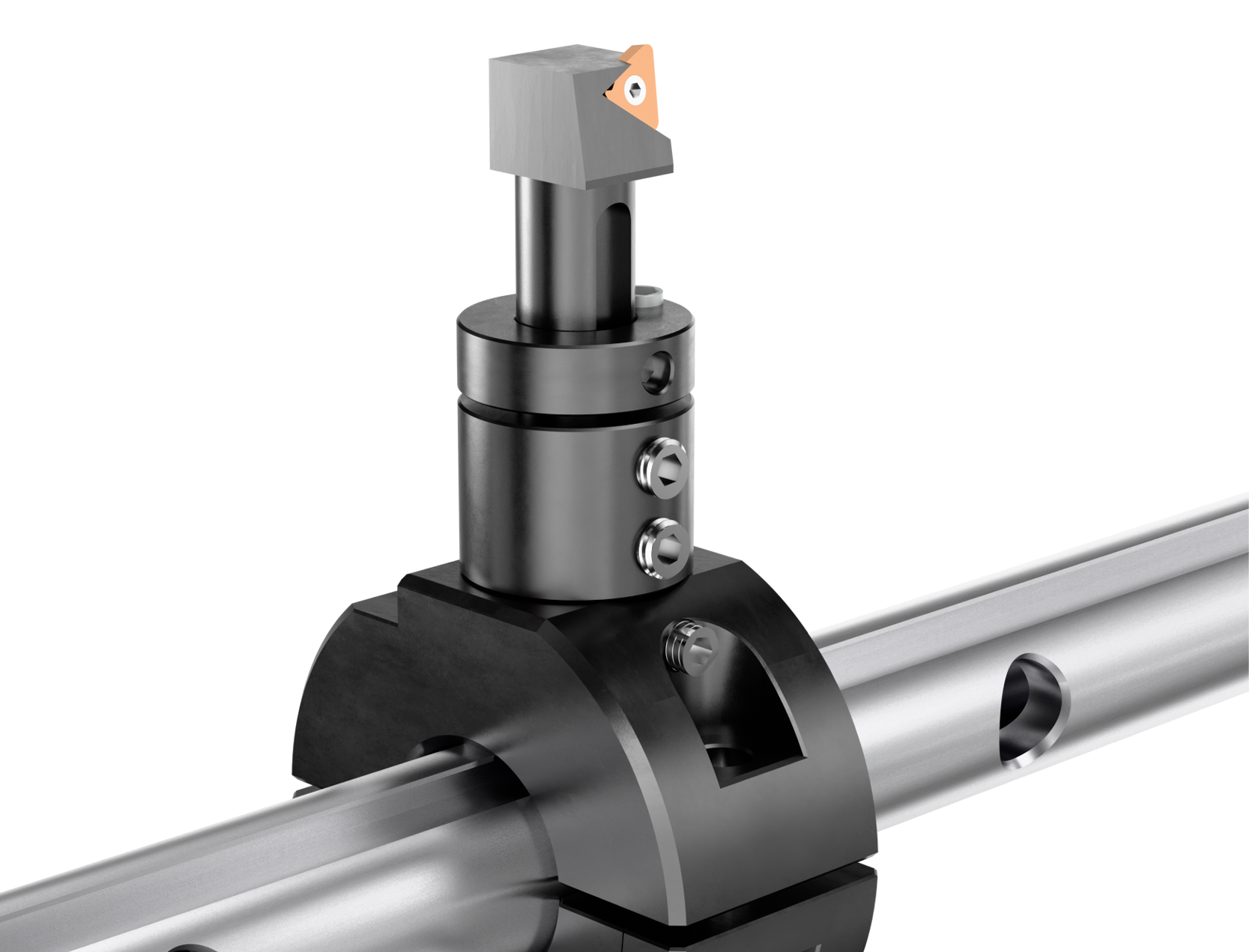

Supercombinata®

The Unique Combo One

La serie Supercombinata, grazie alle ridotte dimensioni e all'estrema versatilità e precisione, può effettuare lavorazioni direttamente in situ riducendo i tempi ed i costi di una riparazione tradizionale. Affidabili, potenti e di semplice utilizzo.

KIT EXTRA

I kit extra sono progettati per conferire grande versatilità di impiego alle alesatrici portatili della serie Supercombinata

ACCESSORI

Una vasta gamma di accessori opzionali dà la possibilità di attrezzare la serie Supercombinata adeguandola alle proprie esigenze

SETTORI DI APPLICAZIONE

Le nostre alesatrici portatili Supercombinata permettono interventi in situ, riducendo così i costi di fermo e di trasporto. Da anni, sono impiegate con successo nei più svariati settori industriali: dall'Eolico, Ferroviario, Idroelettrico, Movimento terra, Navale, Nucleare, Oil & Gas, Ecologia.