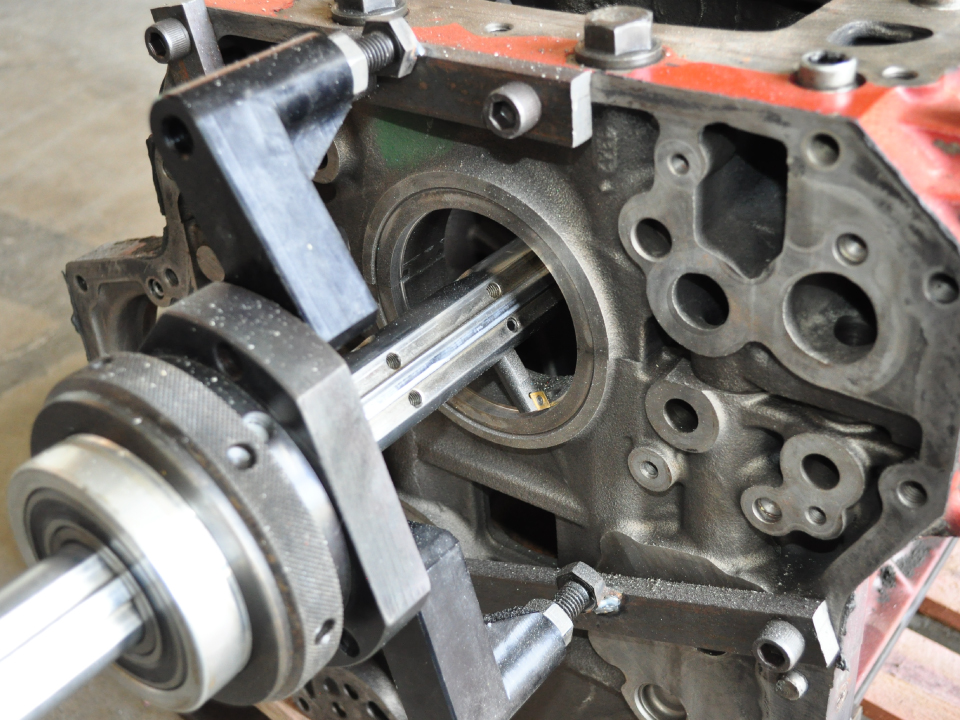

The portable line boring machine is a machine tool used for machining cylindrical holes by removing metal chips in order to increase the diameter and obtain a high finish, both in terms of roughness and tolerance.

There are different sectors of application, just as there are different types of jobs that can be performed with different models of line boring machines created to meet the most different requirements. Let's get to know them together.

What is a portable line boring machine?

From a technical point of view, the portable line boring machine is a machine tool capable of performing mechanical machining operations by chip removal inside cylindrical holes guaranteeing size, coaxiality and concentricity within very tight tolerances.

Commonly, due to its small size and extreme versatility, the portable boring machine is used for on-site repairs, giving the user a considerable advantage in terms of time and cost. In fact, the work carried out directly on site reduces the costs of disassembly and transport to a specialised workshop, minimising downtime and allowing a return to full operation in the shortest possible time.

Application sectors

Portable line boring machines are mainly used in the construction industry. However, over the years more and more applications have been found in a wide variety of sectors: wind, railway, hydroelectric, marine, nuclear, oil & gas, etc.

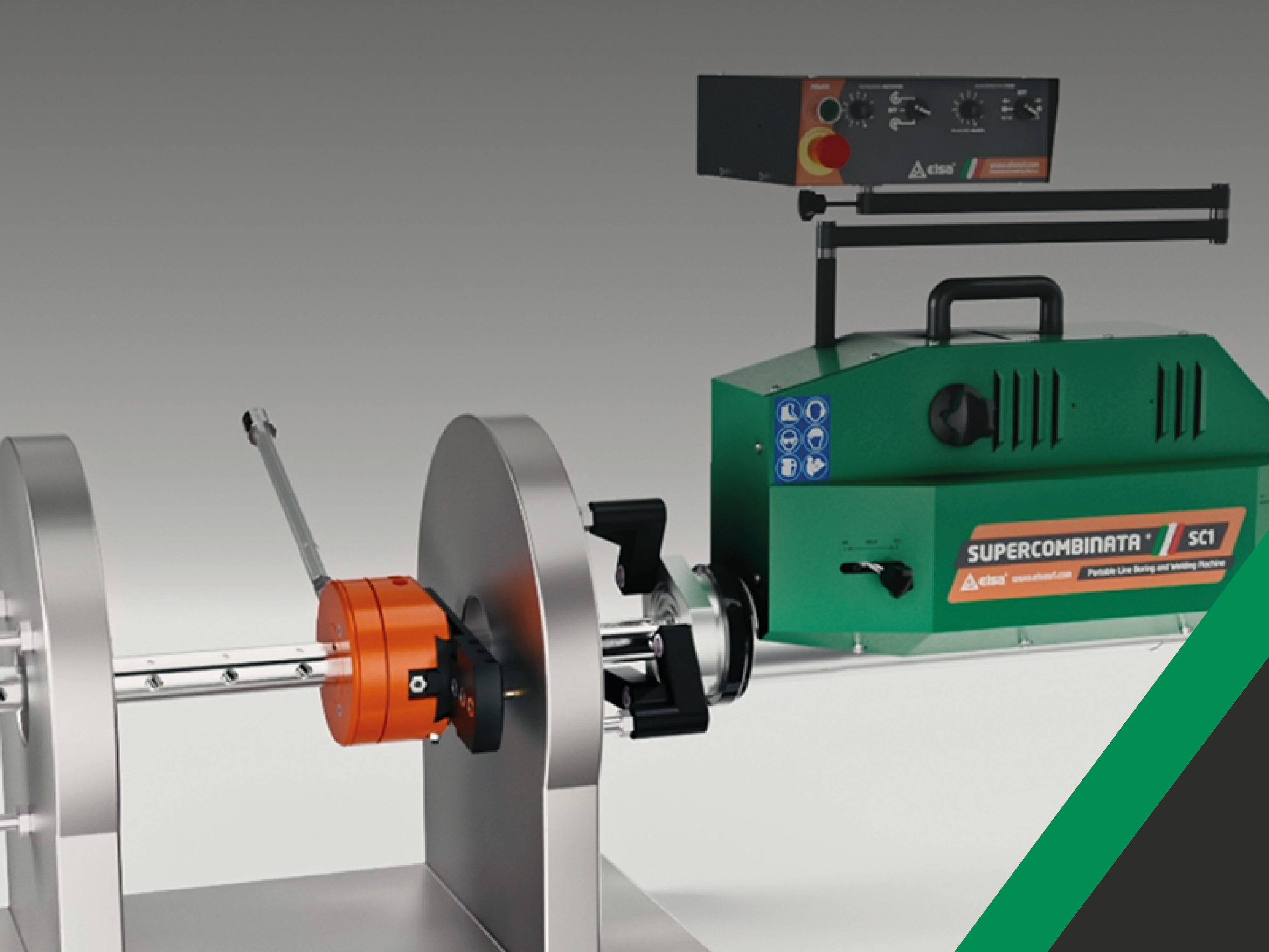

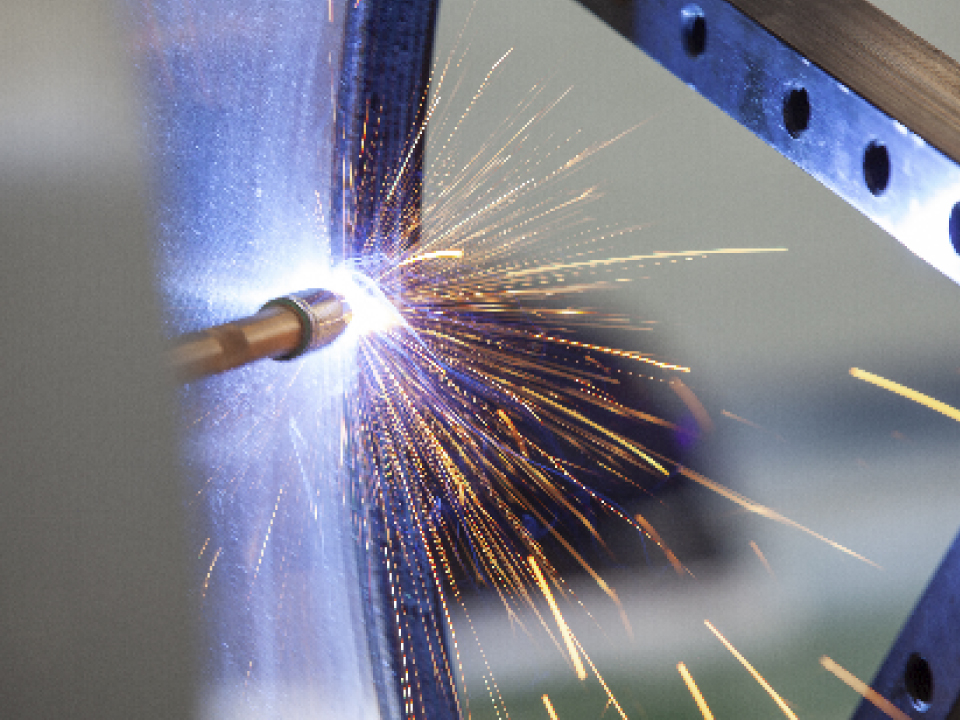

The Supercombinata Portable line boring machine: suitable for any job

The Supercombinata portable boring machine is the multifunctional boring machine designed, developed and manufactured entirely in Italy by Elsa Srl. One of the greatest advantages of the Supercombinata series is its multi-functionality, i.e. the possibility to carry out not only reaming but also high-quality welding with just one installation, one centring and one set-up. In addition to this, the Supercombinata series can be equipped with a series of optional kits that expand its functionality to include machining on small and large diameters, welding and tapping on shafts (external boring), as well as flange facing, creating seeger seats and creating internal threads with various pitches.

Elsa manufactures and sells 5 different extra kits, which can be purchased at the same time or at a later date depending on the boring machine chosen: a kit for reducing the boring range, a kit for machining large diameters, a kit for flange facing, a kit for internal threading and a kit for external boring and overlay welding

The models to choose from

Elsa supplies a range of 6 boring machine models suitable for the most varied requirements in terms of machining range and operating space. Each individual boring machine operates on different dimensions, performing on-site repairs with centesimal precision and close tolerances.

The Supercombined series therefore covers a diameter range from 22 mm of the Supercombinata Easy to 1200 mm of the Supercombinata SC3, which can be obtained with the help of extra kits. The series is enriched by the Compact models with even smaller dimensions, designed to guarantee the same machining quality in reduced operating spaces.

Machining with the Supercombinata provides excellent results in terms of dimensional (H7 tolerance) and geometric precision with roughness in the range of 0.8 - 3.2 µm.

The users

In its 25 years of business, Elsa has evolved as a machine tool manufacturer from a family business to a global company. Today, 97% of production is for export and the sales network is well established with 14 exclusive distributors worldwide.

Visit our website and find out more.

Salvatore Russo , CEO & Line Boring Specialist