How to choose the best portable line boring machine? And what features to look for to make the best investment? Here is a short buying guide.

The elements to be evaluated before the purchase

The purchase of a line boring machine is based on the need to perform machining of cylindrical holes in very special circumstances. As this is an important investment, some aspects should be considered before the purchase. Simply focusing on price is the wrong path that many users take. Instead, it is necessary to evaluate the technical characteristics and the technological contents of the equipment proposed by the various manufacturers in order to correctly evaluate the quality/price ratio.

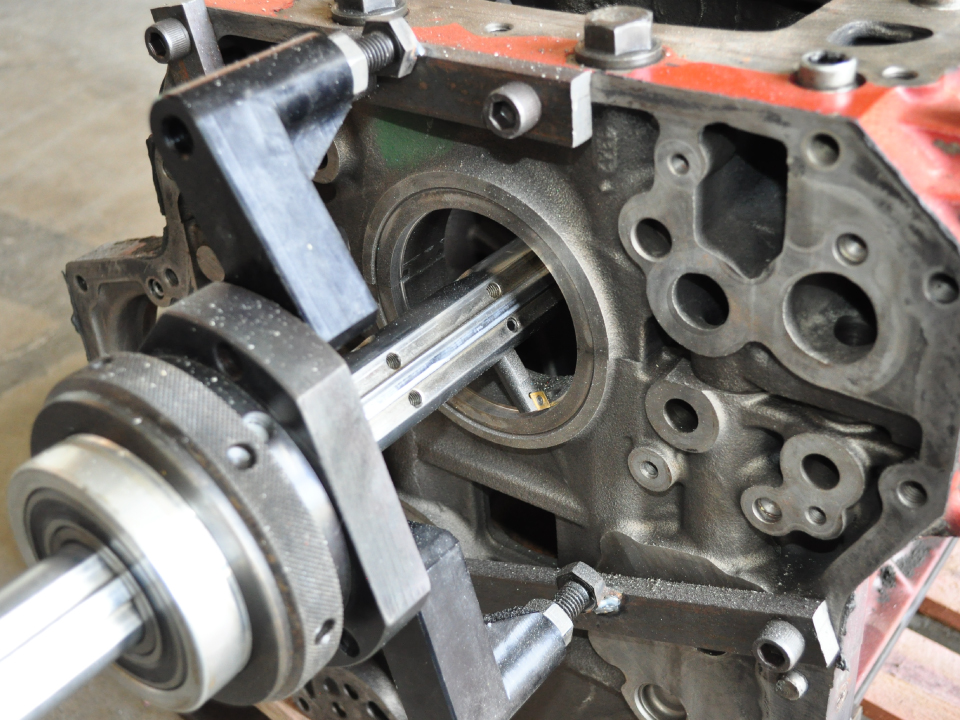

Type of processing and diameter range

The first evaluation to do in order to understand how to choose the best portable line boring machine is related to the type of machining that will be carried out. Some portable line boring machines are multifunctional machines, which means that the functionality of the machines can be extended, with supplied elements and with optional accessories. Therefore, it will be necessary to evaluate what is included in the standard equipment and what would be the cost of the optionals in the event that the equipment should also be used for external boring, facing of orthogonal planes, creation of seats for Seeger rings, threading, tapping, drilling, etc...

Each portable line boring machine model operates in a well-defined diameter range.

The performance and the quality of the machining that can be obtained are related essentially on the mechanical quantities that characterize each specific model, namely the cutting speed and the torque applied on the boring bar.

Engine power and gears

Torque and rotation speed are mechanical quantities that, together with other main cutting parameters, are descriptive of the machining process by chip removal.

The torque provided at the boring bar, parameter to be evaluated during the purchase, determines the cutting force at the cutting head, while the rotation speed determines the cutting speed. For each diameter to be machined, for maximum performance and good machining quality, you should have the required cutting force at the right number of rotations.

Large diameters require low speed and high cutting force, whereas smaller diameters require higher speed and lower cutting force.

The best answer to this specific need is the mechanical gearbox, able to maximize the power delivered by the engine, thanks to the possibility of working with the right gear for each working range.

The gearbox allows to make the best use of the power developed by the motor with maximum flexibility of use, "adapting" maximum torque and speed to the specific needs of the machining.

Longitudinal stroke and length of the boring bar

The boring bar not only performs the rotation motion, but also moves longitudinally through the feed system. The difference here is the stroke: having a wide stroke by steps of more than 300 mm allows you to perform machining in a single stage.

Speaking about the boring bar, it is interesting to notice that the various manufacturers provide boring bars of different length, to be joined if necessary. The presence of the joint determines less precision and stiffness of the boring bar itself. Solutions with fewer joints or couplings should be preferred.

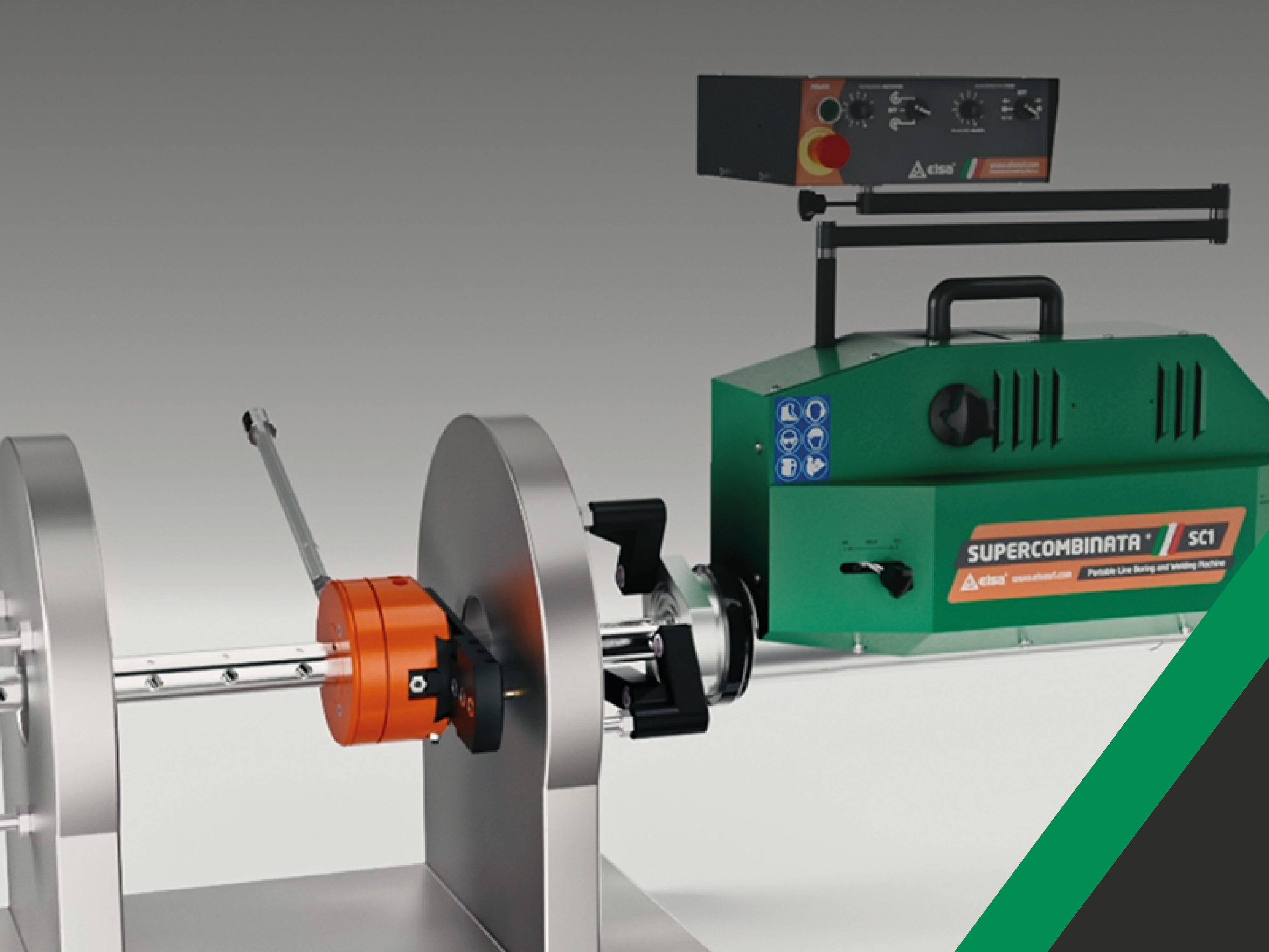

Supercombinata SC1: the point of reference

It is the most iconic and versatile product of the Supercombinata Series and covers the processing range from Ø 42mm to Ø 400 mm.

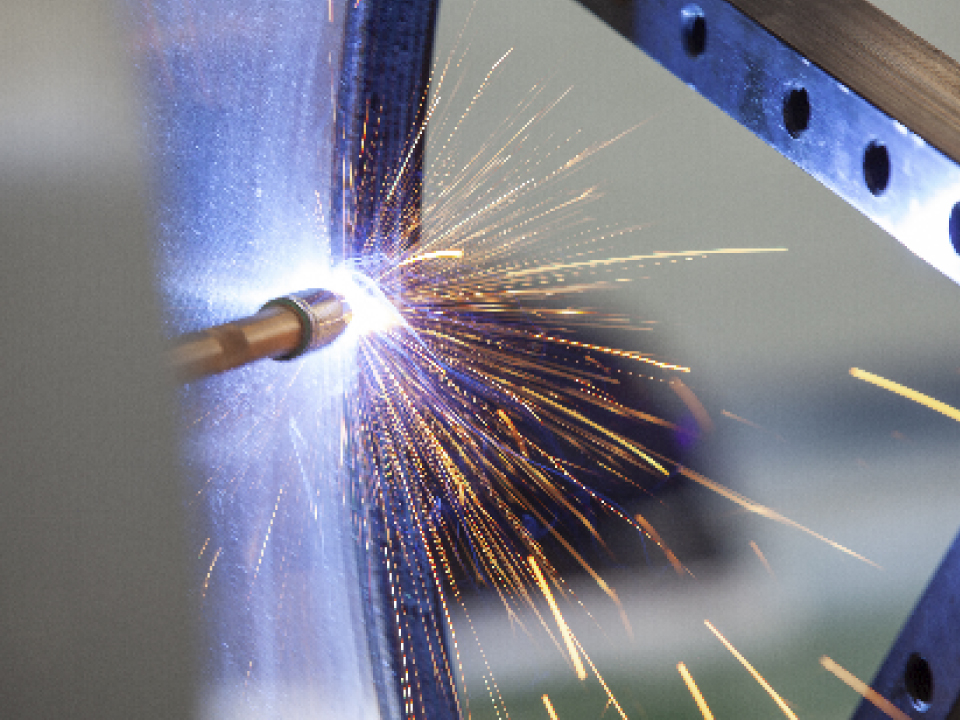

- For machining of: line boring, internal and external overlay welding

- Prepared for: tapping and drilling

- Additional kit for: external turning, threading, facing of orthogonal planes and creations of Seeger seats

- 4-speed gearbox

- Longitudinal stroke unlimited with 350 mm pitch

- Feed: both automatic and manual

- Overlay welding: single mechanical control for rotation and feed

- On request: 110V version and with digital control unit

Supercombinata EASY

Ideal for working diameters up to 250mm, it is the most used equipment in the earthmoving sector and allows to carry out machining starting from Ø 32 mm. It is sold with a reduction kit chosen by the end user, which extends the range of use to diameters less than Ø 32 mm.

- For machining of: line boring and internal overlay welding

- Additional kit for: external turning , facing of orthogonal planes and creations seeger-ring seats

- 2-speed gearbox

- Longitudinal stroke unlimited with 350 mm pitch

- Feed: both automatic and manual

- Overlay welding: single mechanical control for rotation and feed

- On request: 110V version and with digital control unit

For extremely small spaces

The Supercombinata EASY Compact and SC2 Compact are conceived to perform machining in extremely small spaces. The SC2 Compact, after its initial success in the United States, is available also in Europe and worldwide. The two models differ from the processing ranges:

Supercombinata Easy Compact: from Ø 42 mm up to Ø 250 mm with Ø 40 mm boring bar

Supercombinata SC2 Compact: from Ø 62 mm up to Ø 250 mm with Ø 60 mm boring bar

Both portable line boring machines share the same dimensional features.

- For machining of: line boring and internal overlay welding

- Additional kit for: external turning, facing of orthogonal planes and creations Seeger-ring seats

- 2-speed gearbox

- Longitudinal stroke unlimited with 250 mm pitch

- Feed: both automatic and manual

- Overlay welding: single mechanical control for rotation and feed

- On request: 110V version and with digital control unit

We recommend the SC2 Compact for machining where higher flexural stiffness is required.

Supercombinata SC2

It differs from the Supercombinata SC1 for the Ø 60 mm boring bar, for the machining range from Ø 62 mm up to Ø 600 mm and for greater torque available on the boring bar.

- For machining of: line boring, internal and external overlay welding

- Prepared for: tapping and drilling

- Additional kit for: external turning, facing of orthogonal planes and creations Seeger-ring seats

- 4-speed gearbox

- Longitudinal stroke unlimited with 350 mm pitch

- Feed: both automatic and manual

- Overlay welding: single mechanical control for rotation and feed

- On request: 110V version and with digital control unit

This equipment is recommended for use in shipbuilding and heavy metal carpentry.

Supercombinata SC3

Our portable line boring machine equipped with the most powerful motor of the range, is equipped with a Ø 60 mm boring bar and allows to carry out machining in the range from Ø 62 up to Ø 800 mm, extendable to Ø 1200 mm with extra kit.

- For machining of: line boring, internal and external overlay welding

- Prepared for: tapping and drilling

- Additional kit for: external turning, facing of orthogonal planes and creations Seeger-ring seats

- 4-speed gearbox

- Longitudinal stroke unlimited with 350 mm pitch

- Feed: both automatic and manual

- Overlay welding: single mechanical control for rotation and feed

- On request: 110V version and with digital control unit

This equipment is recommended for use in mining, shipbuilding, heavy metal carpentry and oil & gas industry.

Find the most suitable portable line boring machine for your needs, visit our website and find out more, visit our website and discover more.

Giuseppe Simmaco, Marketing Manager