The introduction of portable line boring machines has fundamentally changed the repair industry. Let’s discover together the advantages of an innovation that is still little-known on the global market.

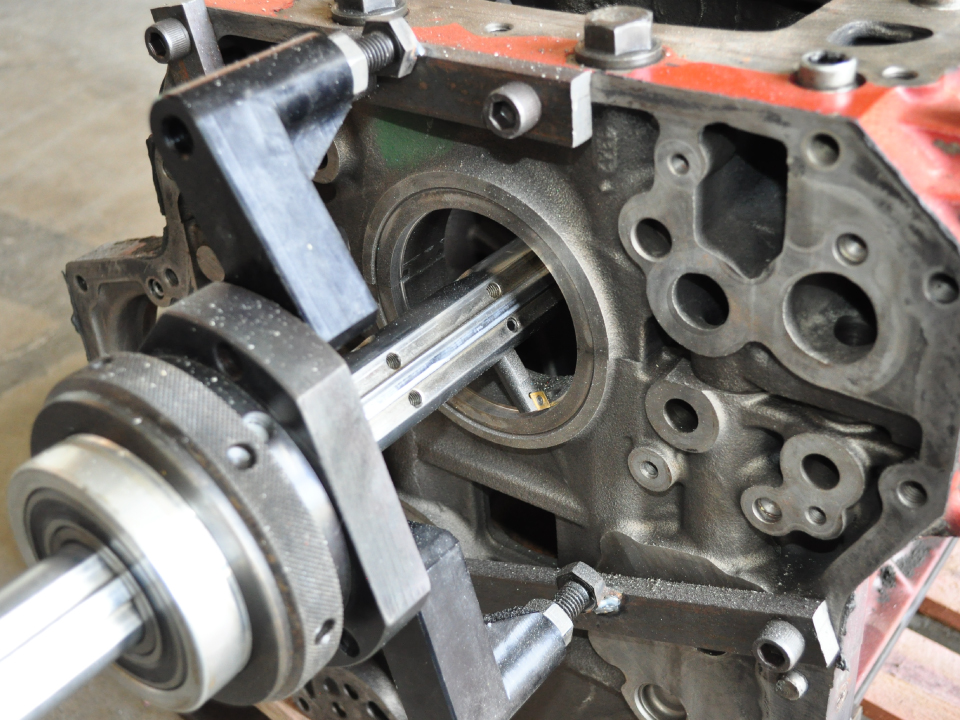

The portable line boring machines grew out of the idea of introducing a portable machine tool capable of performing grinding operations on worn bores directly on the job site by avoiding to dismantle the machines to be repaired. This innovation has brought multiple benefits to mechanics in the industry. Let us discover them together

1 - Time saving

Before the introduction of the portable line borers, the workpiece to be repaired had to be dismantled and transported to the next workshop. In terms of time saving, this type of equipment has caused a real revolution. Let's think of repairs in sectors such as oil & gas, shipbuilding or power generation plants that are usually located far away from repair centres. Machining with portable boring equipment allowed operators to bring the line boring machine on site without the need to transport the workpiece to be repaired, even in extreme conditions.

2 - Cost saving

The second advantage is the cost saving. On-site machining significantly reduces the machine's downtime, keeping it out of service for the shortest possible time without negatively affecting productivity.

Without having to transport the machine to the workshop, and without having to dismantle and assemble the workpiece, significant cost savings are achieved. In addition, there is a reduction in transport costs, which would have resulted from moving the workpiece to the next workshop.

3 - Professional and high-quality repairs

The third advantage is the possibility to offer professional and high quality repairs at any place. While in the, past, a visit to a mechanical workshop was necessary to obtain precise machining operations, today, thanks to the high precision of the portable line borers, the operator can carry out professional repairs with the utmost ease. For example, machining with the Supercombinata series gives an excellent result in terms of dimensional accuracy (tolerance H7) and geometric precision with roughness in the range of 0.8 - 3.2 µm.

A customized solution

The Supercombinata portable line boring machines have been developed to offer a tailor-made solution to all companies that require precise and professional repair in the shortest time possible. Elsa machines have been successfully used for over 25 years by our customers in a wide range of industries: wind energy, railways, hydroelectric, earthmoving, marine, nuclear, oil & gas.

Most common applications

The Supercombinata series unscrewing machines are used on all installations and industrial machines where there are bores to be repaired:

- Wind energy: repair of wind turbines.

- Railways: repair and construction of rolling stock and equipment for railways and subways.

- Hydroelectric: Repair of coupling holes, bearings, valve seats, flanges, etc.

- Earthmoving: Repairs of tunnel machinery, earthmoving machinery, heavy and light metal construction, cranes, hydraulic cranes, agricultural equipment, concreting equipment, etc.

- Shipbuilding: repairs of engine blocks, stern flaps, valves, blind holes, orthogonal surfaces, propeller axis alignment, engine attachment, etc.

- Nuclear power: maintenance and repair of nuclear power plants.

- Oil & Gas: repair of gas pipelines and refinery equipment.

Elsa can help you expand your business and become a successful company. Choose the portable line boring machine that suits your needs best, visit our website and find out more.

Bonifacio Monti, Mechanical Engineer