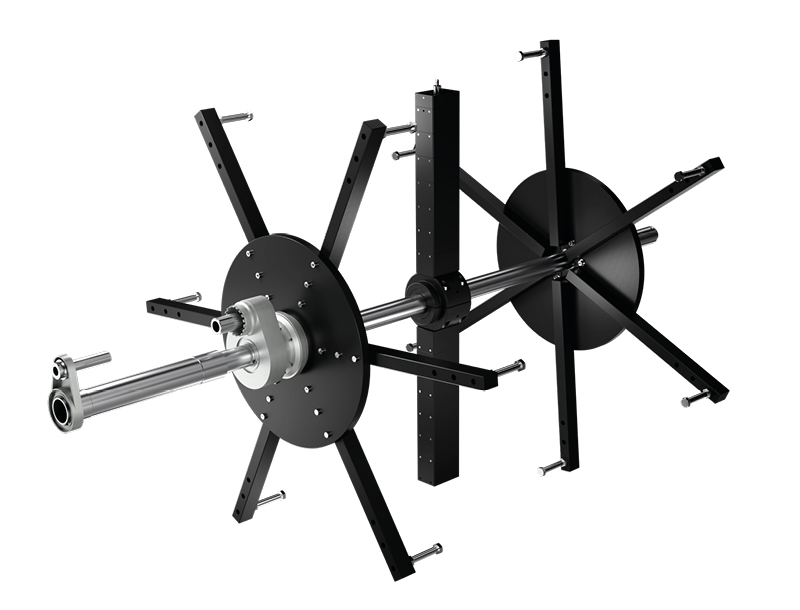

EXTRA KITS

BIG DIAMETERS

Ø 400 - 1700 mm (15,75"- 66,93")

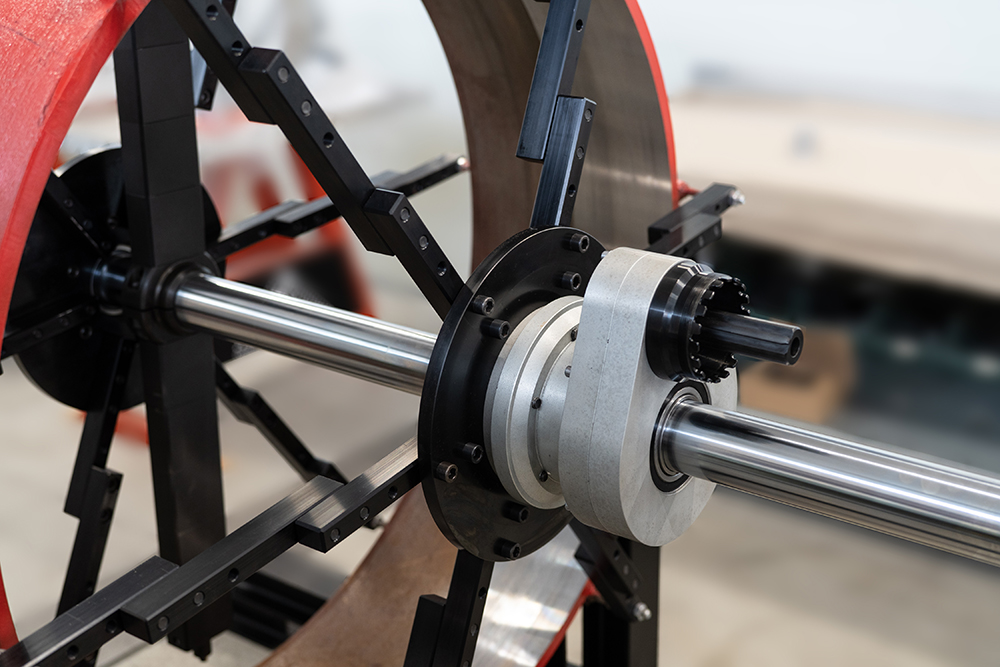

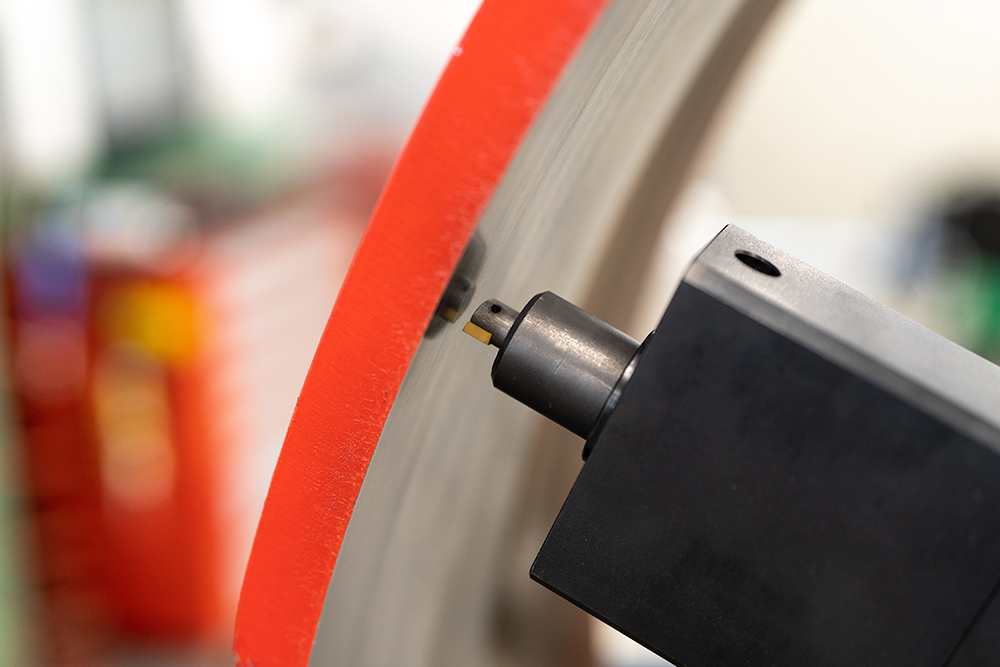

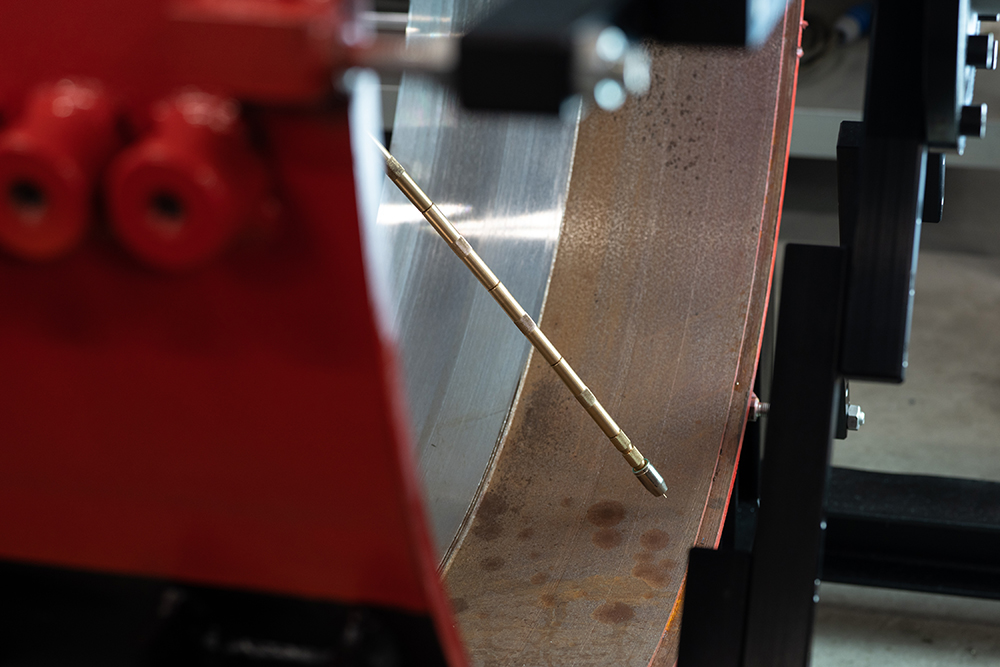

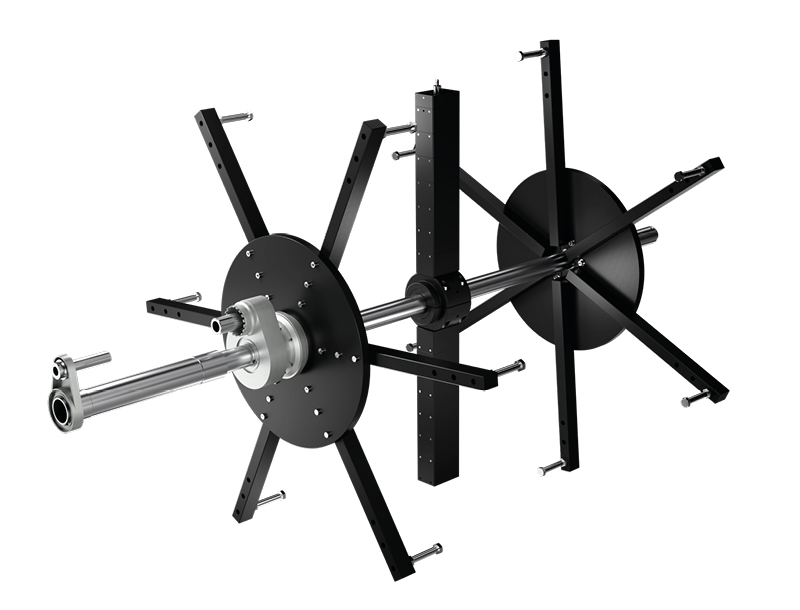

The kit has been designed to extend the standard machining range of the portable line boring machine Supercombinata, allowing internal line boring and overlay welding from Ø 400 mm to Ø 1700 mm.

Also available for operating leasing. More information.

Models

ked00180

- SC1

Ø 400 - 600 mm (15,75" - 23,62")

ked00360

- SC2

Ø 600 - 800 mm (23,62" - 31,50")

ked00366

- SC3

Ø 800 - 1200 mm (31,50" - 47,24")

ked00367

- SC3

Ø 1200 - 1700 mm (47,24” - 66,93”)

You might also be interested in…

BASIC

Line boring: Ø 22 - 120 mm (0,87" - 4,72")

Internal welding: Extra kit

EASY

Line boring: Ø 22 - 250 mm (0,87" - 9,84")

Internal welding: Ø 25 - 250 mm (0,98" - 9,84")

EASY Compact

Line boring: Ø 42 mm to Ø 250 mm (1,65" - 9,84")

Internal welding: Ø 42 mm to Ø 250 mm (1,65" - 9,84")

SC1

Line boring: Ø 42 - 400 mm (1,65 "- 15,75")

Internal welding: Ø 42 - 400 mm (1,65 "- 15,75")

SC2

Line boring: Ø 62 - 600 mm (2,44" - 23,62")

Internal welding: Ø 42 - 600 mm (1,65" - 23,62")

SC2 Compact

Line boring: Ø 62 - 250 mm (2,44" - 9,84")

Internal welding: Ø 42 - 250 mm (1,65" - 9,84")

SC3

Line boring: Ø 62 - 800 mm (2,44" - 31,50")

Internal welding: Ø 42 - 800 mm (1,65" - 31,50")