Discover how portable line boring machines optimize repairing jobs in the marine industry and how they reduce downtime and ensure precise result in maintenance.

1 - The challenge

Every day, many companies in the marine industry face a critical challenge: the need to reduce downtime and optimize maintenance and repair work on their vessels. Critical components such as propeller housings, propeller shaft bearings and coupling flanges require precise and rapid intervention to keep ships in perfect working order.

2 - The solution

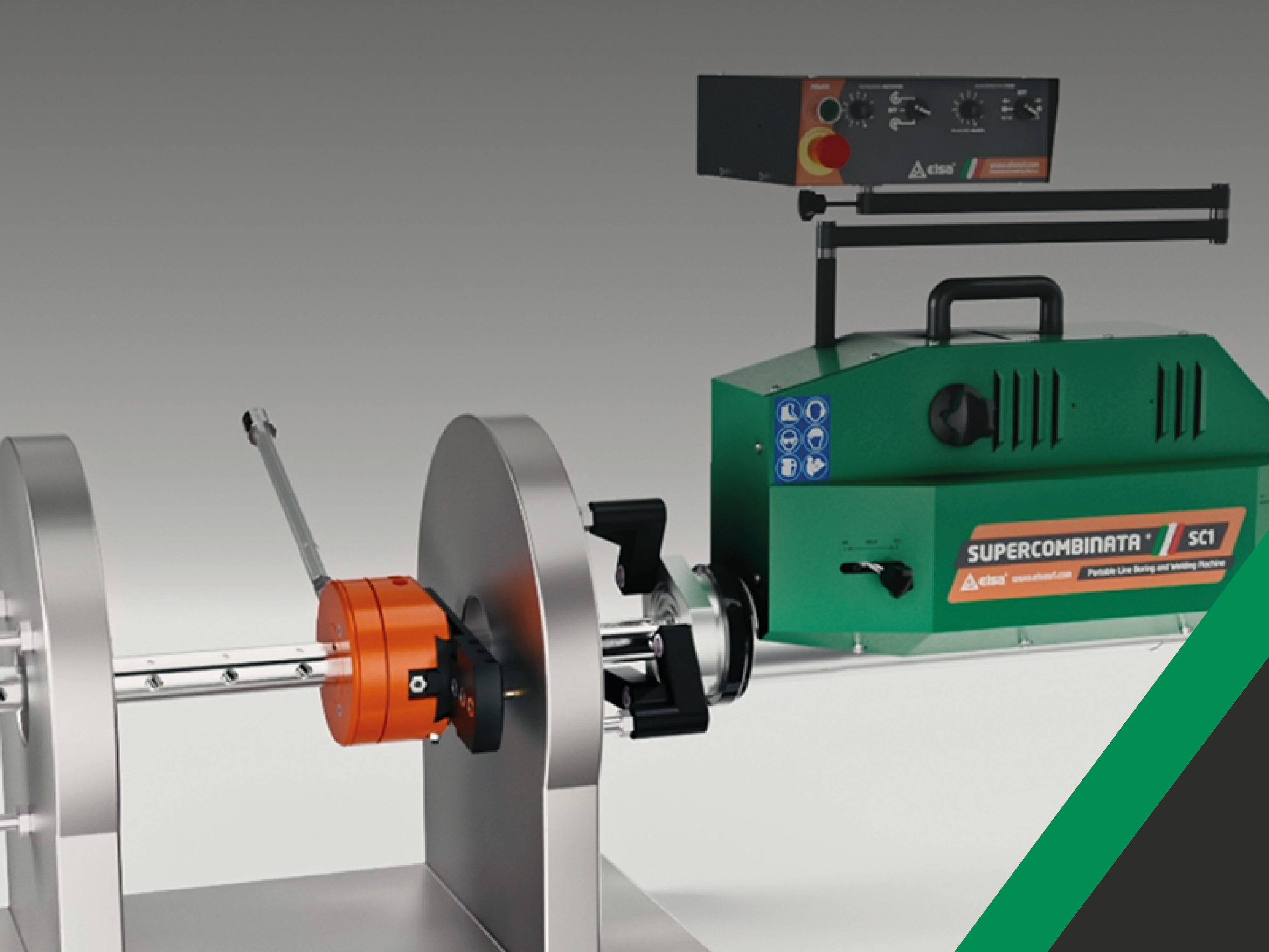

The Supercombinata range of portable line borers has proven to be an ideal and versatile solution to tackle these problems, enabling the repair and completion of a variety of components in vessels without the need to dismantle and transport them. The high precision and operational efficiency of Elsa's worldwide used product enables companies to drastically reduce downtime and maximize the productivity of their marine operations.

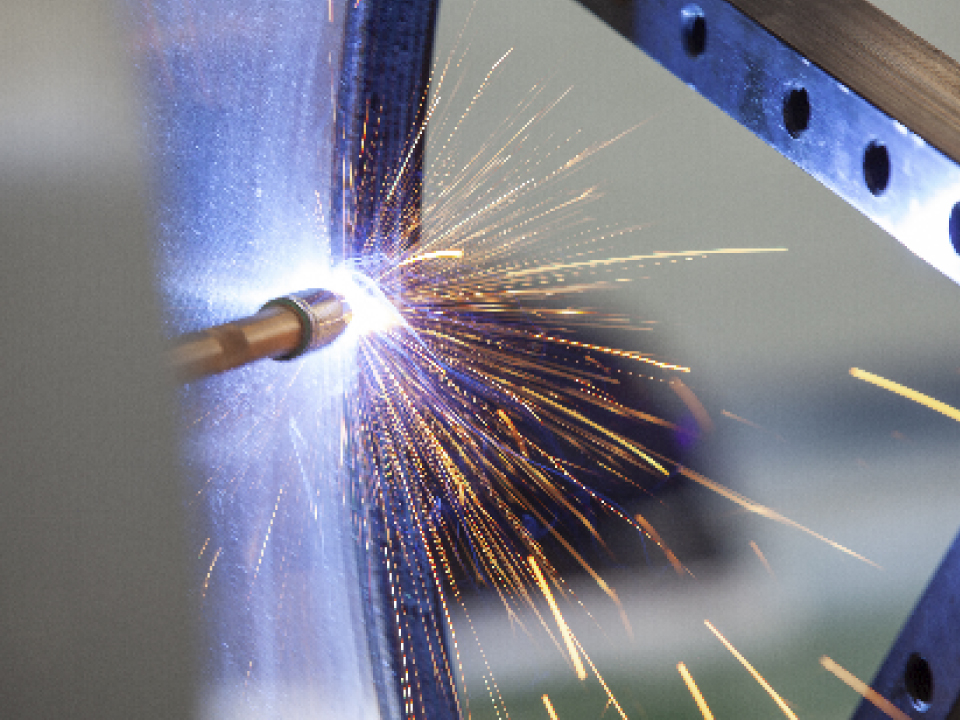

By applying the skills acquired over many years to large on-site machining projects and continually developing special line boring machines to tackle even the most difficult cases, Elsa is at the forefront of portable line borers and techniques for precision on-site machining of equipment and industrial machines.

3 - Maintenance

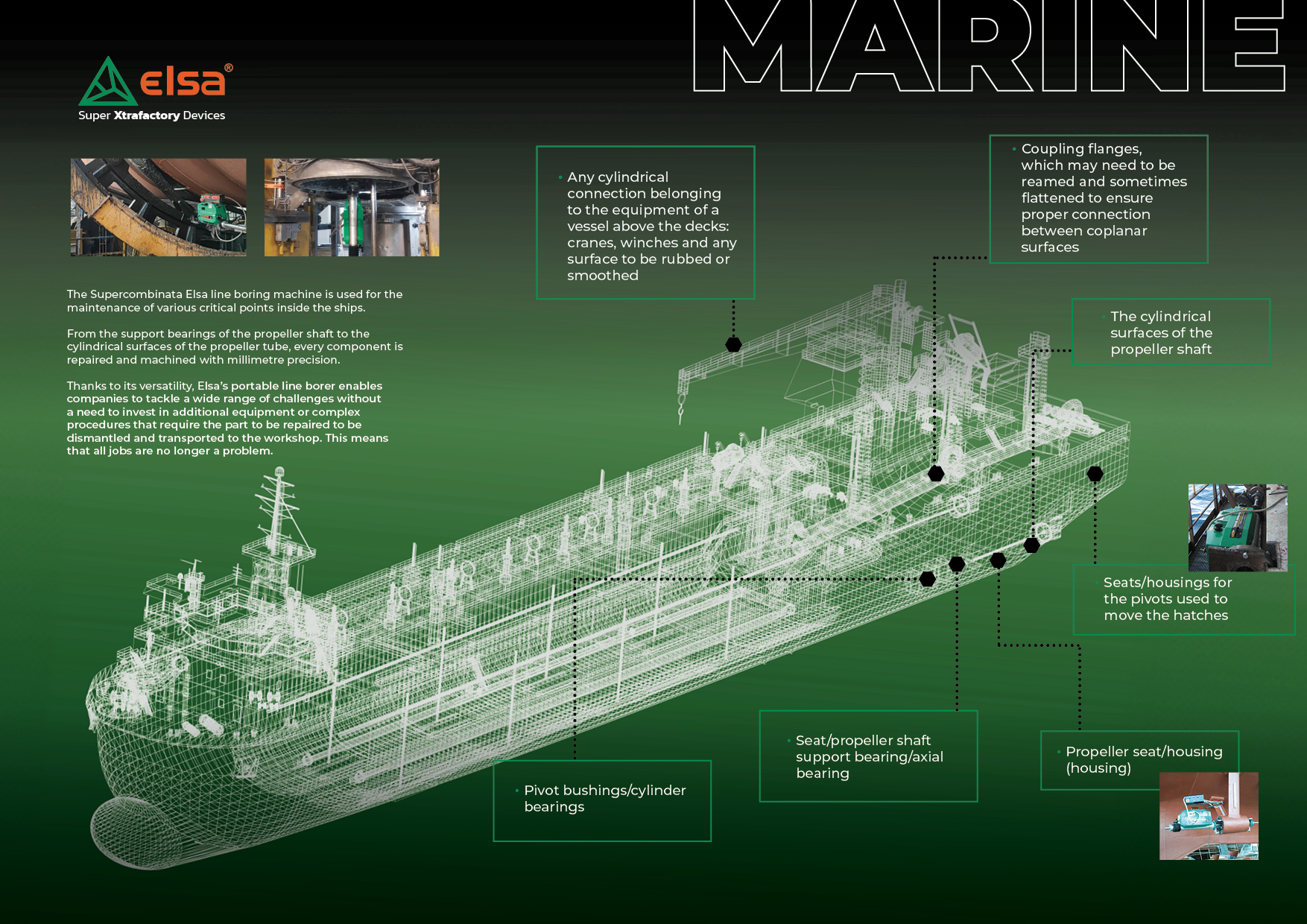

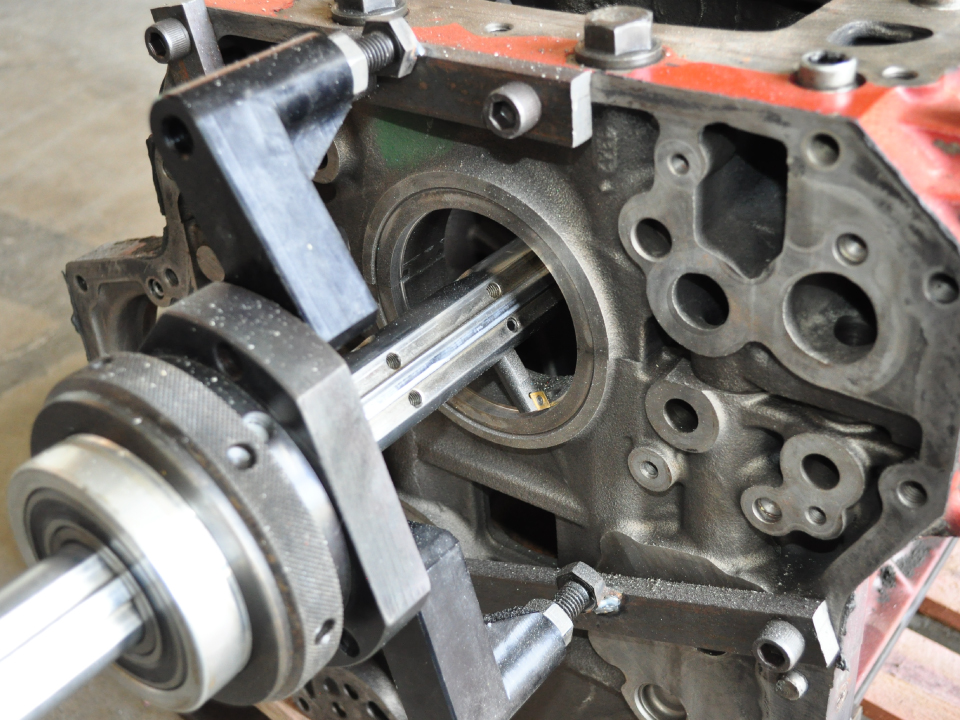

The Supercombinata Elsa line boring machine is used for the maintenance of various critical points inside the ships. From the support bearings of the propeller shaft to the cylindrical surfaces of the propeller tube, every component is repaired and machined with millimetre precision. Thanks to its versatility, Elsa's portable line borer enables companies to tackle a wide range of challenges without a need to invest in additional equipment or complex procedures that require the part to be repaired to be dismantled and transported to the workshop. This means that all jobs are no longer a problem.

In particular, the portable Supercominata line boring machine enables mechanical reworking on certain parts such as:

- Propeller seat/housing (housing);

- Seat/propeller shaft support bearing/axial bearing;

- Coupling flanges, which may need to be reamed and sometimes flattened to ensure proper connection between coplanar surfaces;

- pivot bushings/cylinder bearings;

- the rudder stock;

- the cylindrical surfaces of the propeller shaft;

- seats/housings for the pivots used to move the hatches;

- any cylindrical connection belonging to the equipment of a vessel above the decks: cranes, winches and any surface to be rubbed or smoothed.

4 - The result

Downtime is significantly reduced, enabling longer vessel uptime and an overall improvement in operational efficiency. In addition, the precision and reliability of the Supercombinata line boring machines help to ensure the safety and integrity of the vessels and minimise the risk of breakdowns and malfunctions.

The experience of Astillero Naval Federico Contessi y Cía. S.A.

Elsa's Supercombinata is a high-performance machine with which we achieve an excellent result for the axle line bushings on 100% of the boats we build.

We also use it for many repairs to improve the axle line bearings, reduce vibrations and extend the life of the propeller shaft.

Machining times are considerably shorter and you get a high-quality product with an excellent surface finish.

The versatility of the Supercombinata is remarkable. We are so satisfied with it that we bought a second machine less than two years after the purchase of the first.

Conclusions

Thanks to their versatility to machine a wide range of critical components quickly and accurately, the Supercombinata series enables companies in the industry to optimize their workflows, reduce costs and improve overall productivity. Elsa's Supercombinata portable line boring machine makes repairs in the marine industry more efficient, safer and more reliable by removing large amounts of metal in a short amount of time while maintaining precise alignment and tight machining tolerances.

Elsa's Supercombinata line boring machine is a valuable tool to ensure maximum uptime of vessels. Its performance in machining a wide range of critical components quickly and effectively makes it an essential ally for the shipbuilding industry, ensuring continuity of operations and maximizing vessel safety.

We are confident that we can make a difference for you too.

Choose the right line boring machine for your needs

Roberto Marino, Mechanical Engineer