Elsa's Supercombinata is an indispensable tool for improving work efficiency, reducing costs and ensuring safety.

Let's discover together the features and advantages of this extraordinary tool.

Elsa's Supercombinata: the multifunctional boring machine for industrial machinery

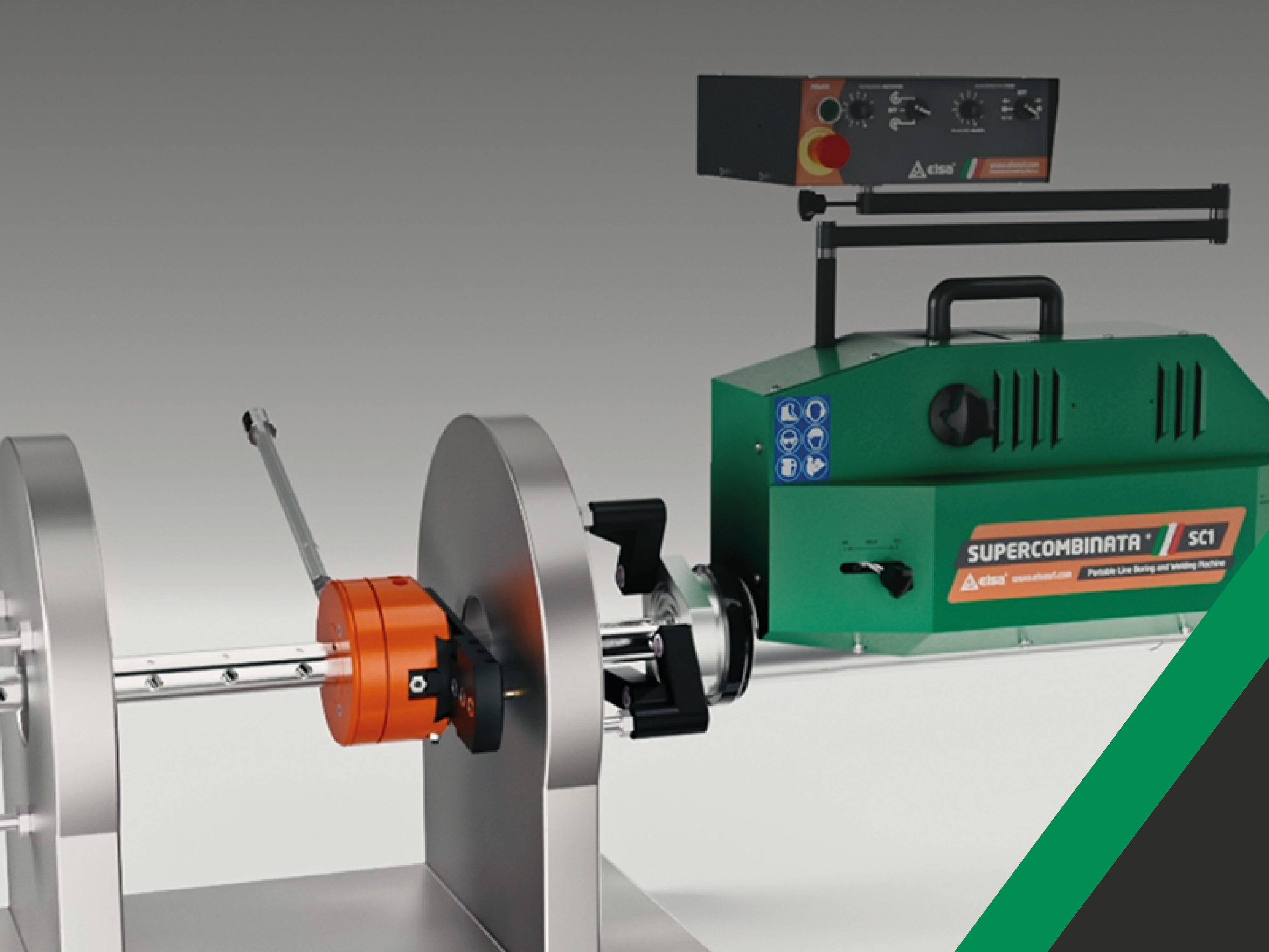

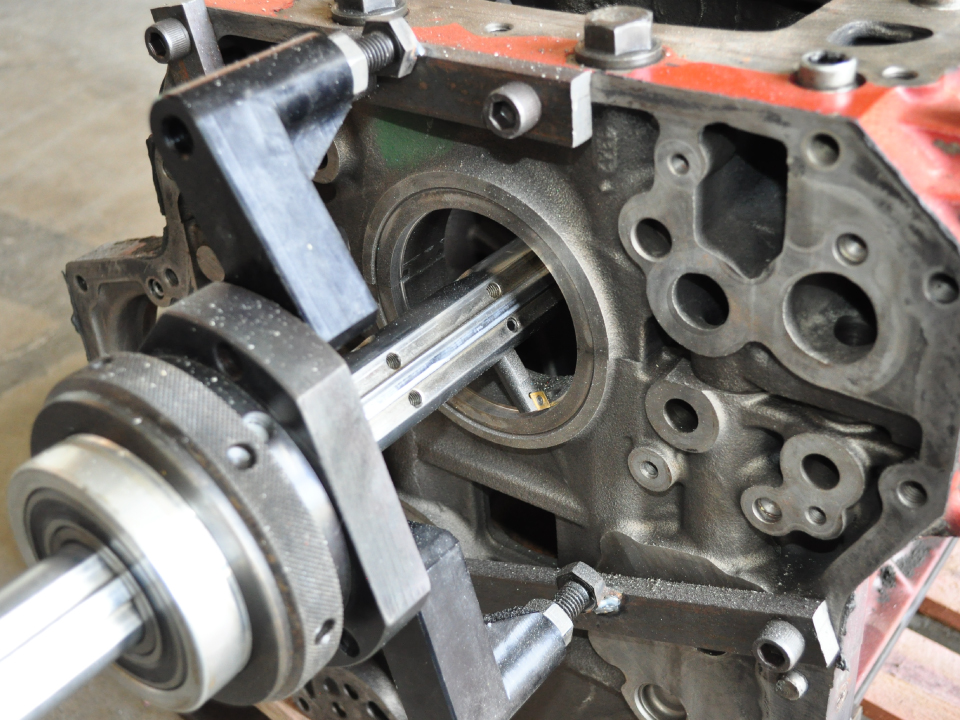

When it comes to maintenance and repair of heavy construction machinery, the tooling makes the difference. The Supercombinata machine is a portable, multifunctional tool designed for maintenance and repair operations on industrial machinery. Developed for boring and overlay welding, it allows reconditioning operations to be carried out directly on site, thus avoiding the need to dismantle heavy equipment and drastically reducing downtime.

Features of the Supercombinata machine

-

Versatility: designed for different types of applications, the Supercombinata machine is a strategic investment for companies wishing to optimise maintenance and repair operations.

-

Portability: lightweight and easy to handle, it can be used directly on site, reducing downtime and costs related to transport and workshop repairs.

-

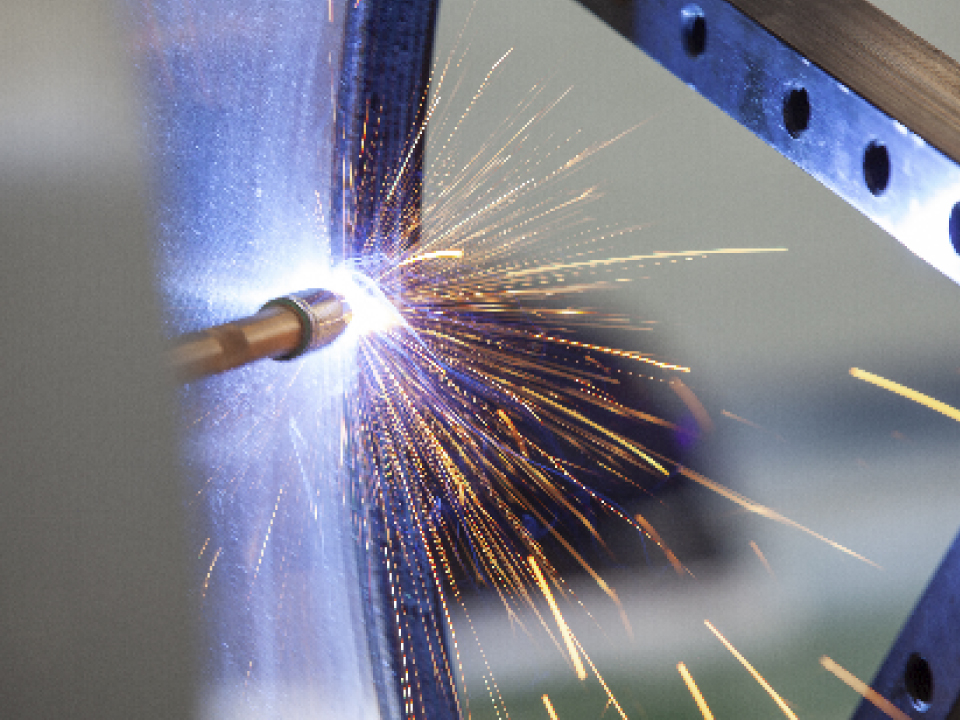

Precision: equipped with advanced mechanics, the Supercombinata machine performs boring and overlay welding with high precision, thus regenerating components.

-

Ease of use: the intuitive design makes the Supercombinata easy to use even for less experienced operators.

Advantages for earthmoving and construction professionals

- Reduced downtime: on-site maintenance allows for a quick resume of operations, reducing losses.

- Cost savings: it saves transport costs to the workshop and allows repair of components, significantly reducing maintenance costs.

- High quality machining: precision boring and overlay welding extends the life of machinery, reducing the frequency of maintenance operations.

- Increased safety: regular maintenance with the Supercombinata machine reduces the risk of malfunctions and accidents, contributing to a safe working environment.

- Multiple machining operations with one machine: the Supercombinata has several extra kits for advanced machining operations such as flange facing, internal threading and external turning.

- Wide-ranging industrial applications: used in several fields such as windpower, railway, hydropower, earthmoving, marine, nuclear and oil & gas, the Supercombinata machine meets repair and maintenance needs on complex machinery.

Field of application of the Supercombinata

The portable line boring machine Supercombinata is ideal not only for earthmoving and construction machinery, but also for:

- Windpower: repair of wind turbines.

- Railway: maintenance of rolling stock and railway equipment.

- Hydropower: repair of components such as bearings and valve seats.

- Earthmoving: for earthmoving machinery, lifting equipment, cranes, and agricultural equipment.

- Marine: machining of cylinder blocks, hatches and engine components.

- Nuclear: maintenance of nuclear plants.

- Oil & Gas: repair of gas pipelines and refinery plants.

Customer testimonials

Many customers confirm the high quality and reliability of the Supercombinata. Here is an example:

“Investing in a machine like the Supercombinata is a guarantee of long life and reliability over time. Our machine, purchased in 1997, is still running today with its fourth owner, without ever having required an engine repair. High quality and durability ensure a return on investment for many years. Bore America LLC”

Click here for more testimonials.

Conclusion

The Supercombinata represents a game changer in industrial maintenance. With its innovative features and tangible advantages, it is an indispensable tool for companies that want to improve work efficiency, reduce costs and ensure safety.