Lenik Wytaczanie specializes in repairing worn holes of heavy earthmoving and construction machinery.

The users

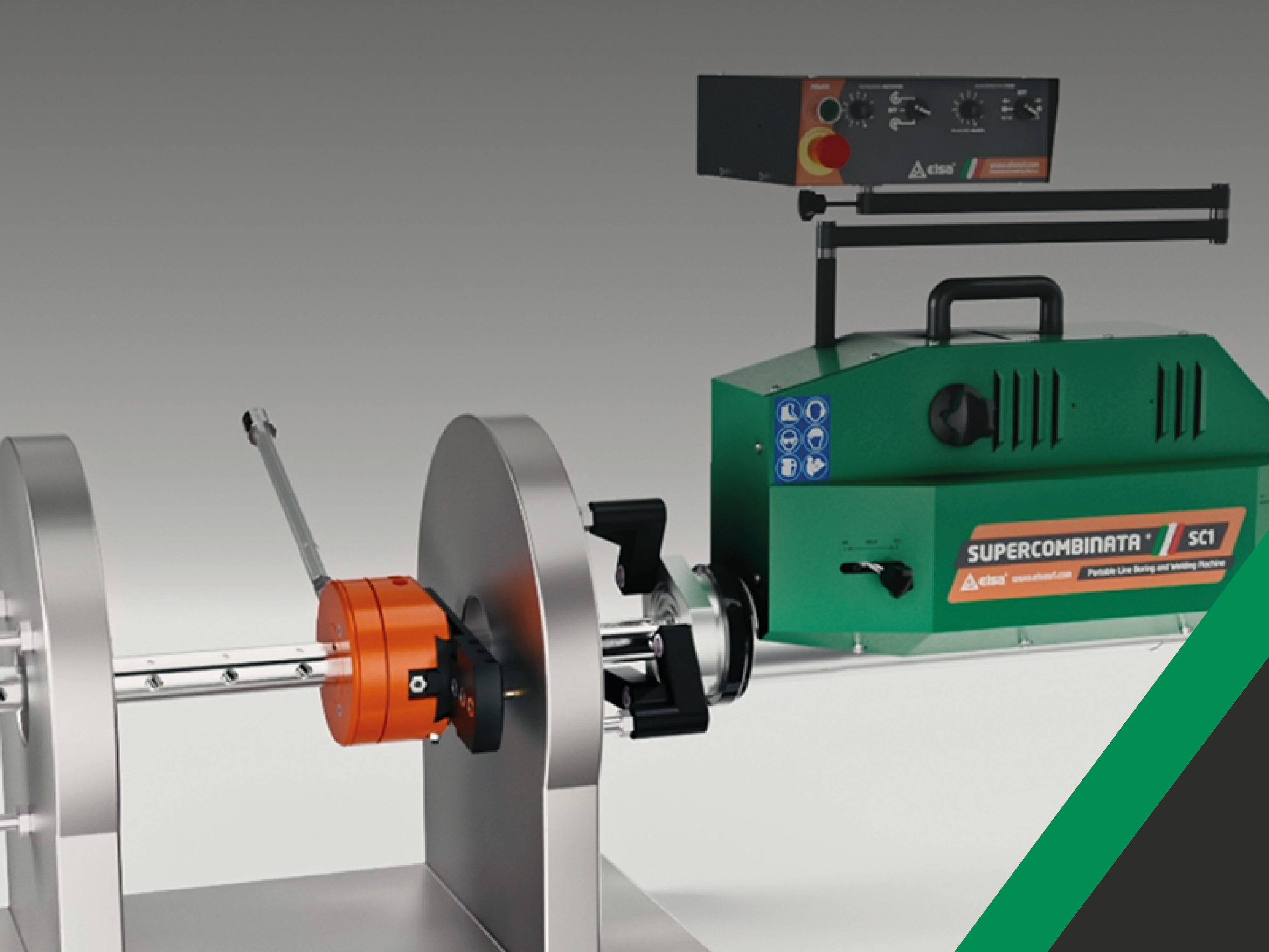

Lenik Wytaczanie, based in Radlin in southern Poland, deals with specific repairs on small and large construction and earthmoving machinery. The work involves boring, overlay welding and finishing the holes to the required dimensions. Since 2023, they have been happy owners of a Supercombinata machine used daily in their operations.

Mr Lenik Krzysztof, the owner of the company, kindly answered our questions by detailing one of the latest successfully completed repair jobs.

The challenge to face

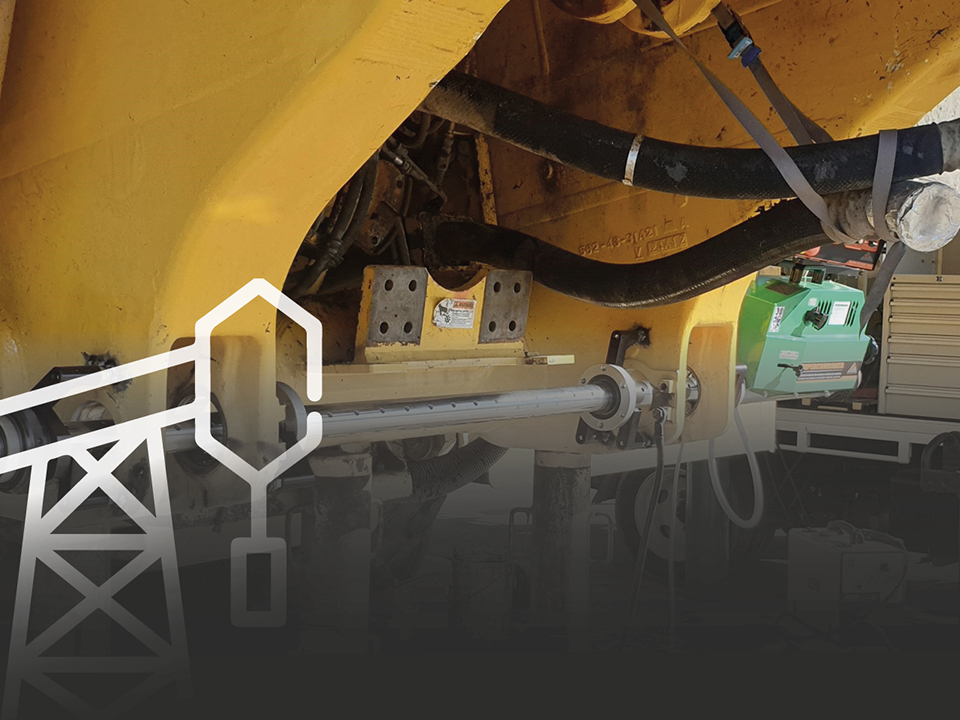

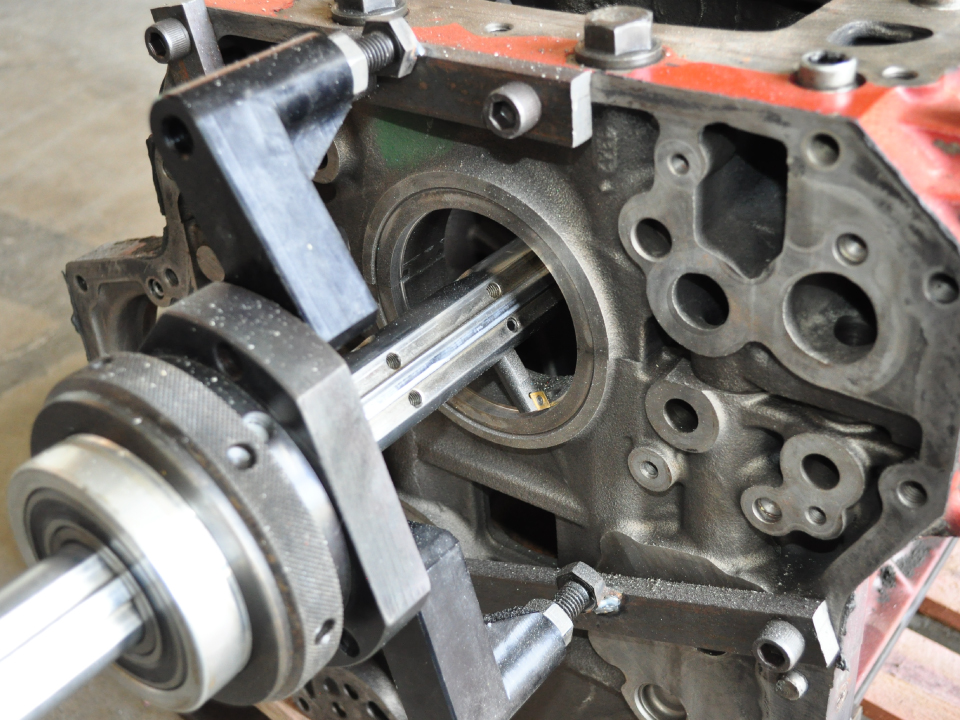

Maintaining heavy construction machinery requires precise solutions and advanced tools to minimise downtime and reduce operating costs. For the repair of our Caterpillar D6M LGP bulldozer, we faced the challenge of restoring the pin seats of the main crossmember anchor bushings. To carry out this repair, we chose the portable line boring machine Supercombinata Easy, whose advanced accessories allowed fast and precise operations.

The Solution

The repair included restoring the original dimensions of the holes by overlay welding and boring. During the process, we used the following:

-

Facing head, which enables precise levelling of surfaces.

-

Welding nozzle, which allows regeneration of worn and damaged areas.

We chose the portable line boring machine Supercombinata for its integrated solutions that allow both welding and facing, greatly simplifying and speeding up the process.

The Repair Procedure

Repair operations were carried out in two key stages:

-

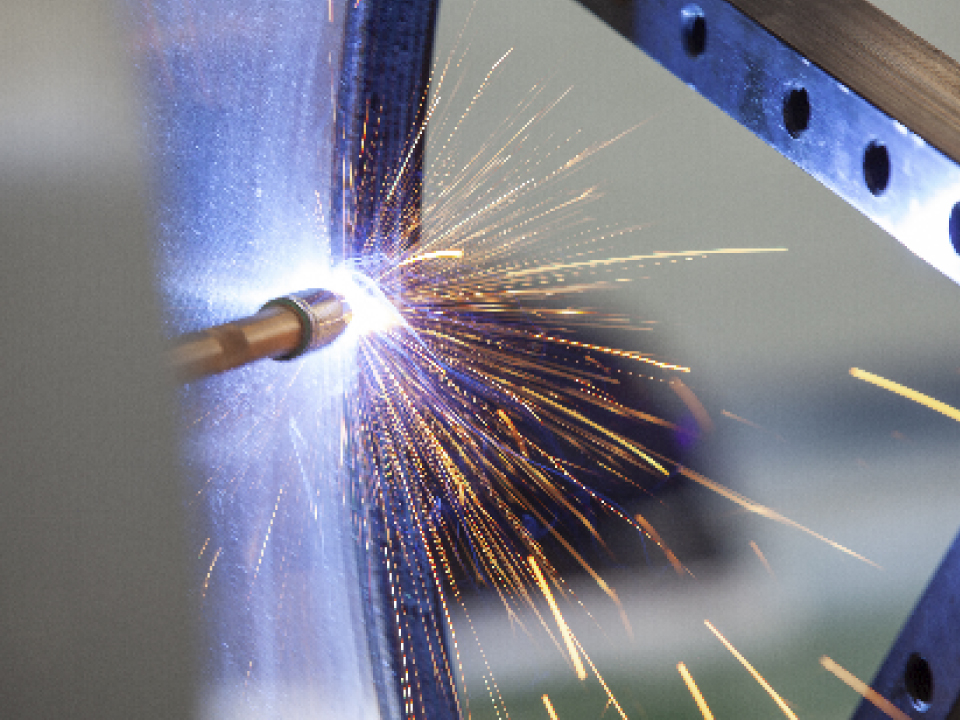

Overlay welding of worn holes: the use of the welding torch allowed the holes to be restored and prepared for subsequent machining.

-

Boring and facing: thanks to the facing head and the precise adjustment system of the boring machine, the holes were restored to their original dimensions.

Precision machining ensured not only high surface quality but also dimensional precision.

The Results Achieved

Thanks to the advanced technology of the Supercombinata Easy machine, the repair process was much more efficient. The accurate measurement and adjustment of the machine allowed for a machining process perfectly tailored to our needs, leading to significant benefits:

-

Reduction of repair times by up to 50%: valuable time savings, which contributed to a quick return of the machine to service.

-

Cost reduction: the fact that the bulldozer did not need to be transported to an external workshop and the reduction in downtime resulted in significant cost savings.

Conclusion

The use of the Supercombinata EASY machine for the repair of the Caterpillar D6M LGP turned out to be a winning choice. Its innovative solutions, such as overlay welding and precise surface facing, enabled a high-quality repair to be achieved in a short time and cost-effectively. Elsa's boring machine technology is an indispensable support in the maintenance operations of heavy earthmoving and construction machinery, which would require much more time and cost if carried out using traditional methods.