Discover Elsa's kits and accessories: innovative solutions to extend your on-site machining, guaranteeing maximum precision and efficiency.

Advanced solutions to meet every need

Elsa stands out in the industrial landscape for its ability to meet the ever-changing needs of the market. The range of extra kits and accessories is designed to:

- improve precision;

- increase the efficiency of machining operations;

- guarantee unrivalled versatility.

Top quality and performance

Every component in the Elsa catalogue is the result of research and innovation, and is made from high-quality materials to:

- guarantee durability;

- high performance;

- meet the most rigorous industry standards;

- meet customer expectations.

In a context of increasing competitiveness, investing in high quality kits and accessories represents:

- a strategic choice;

- a necessity to maintain a competitive advantage.

Each product, whether a kit or an accessory, is designed to optimise performance and offer maximum versatility to meet the specific needs of every customer.

Elsa's extra kits

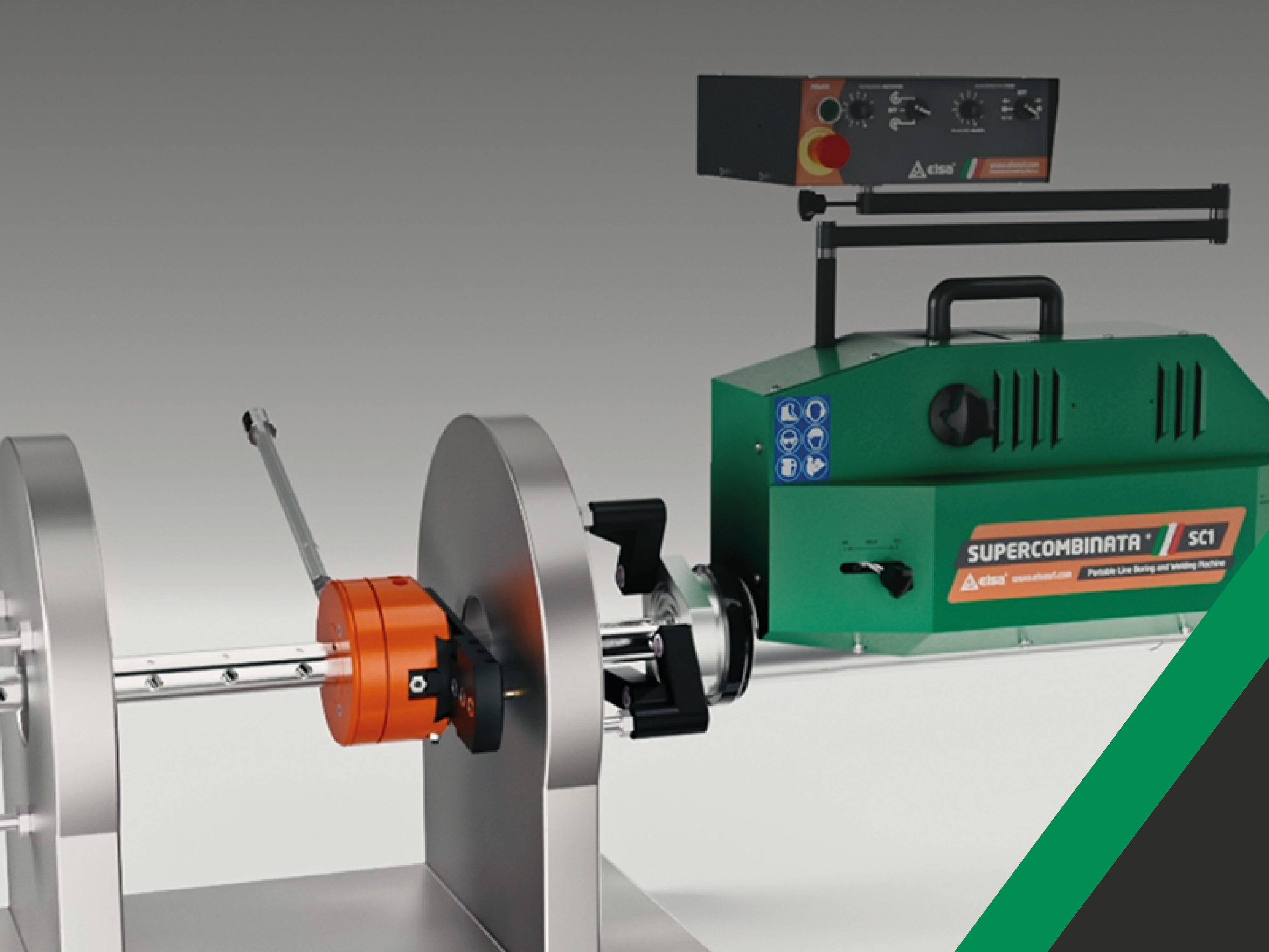

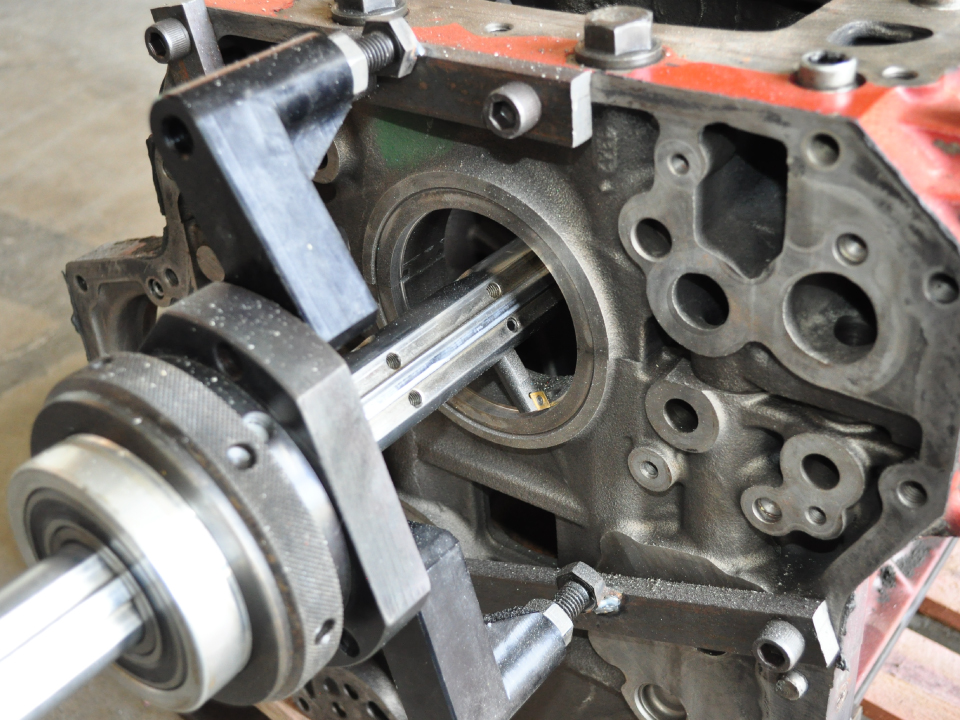

Elsa has designed several kits, whose function is to extend the range of machining operations specific to Supercombinata line boring machines, adapting them to individual operations requiring high precision and superior performance.

Line boring reduction kit

Equipped with specially designed bushings, the bore reduction kit makes it possible to extend the standard machining range of the Superconbinata by reducing the minimum machining diameter to Ø 20, 30 or 40 mm.

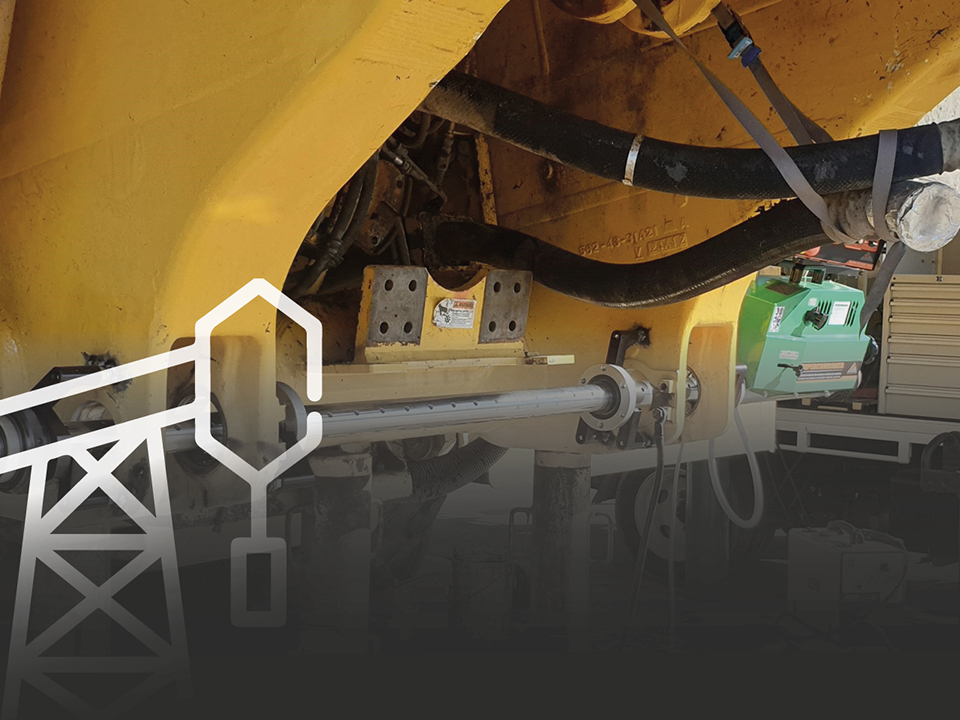

The possibility of adapting the machining dimensions to the required specifications is crucial in all those sectors, such as earth moving and agricultural machinery, where the machining range is focused on very small diameters.

Find out more about the reduction kit

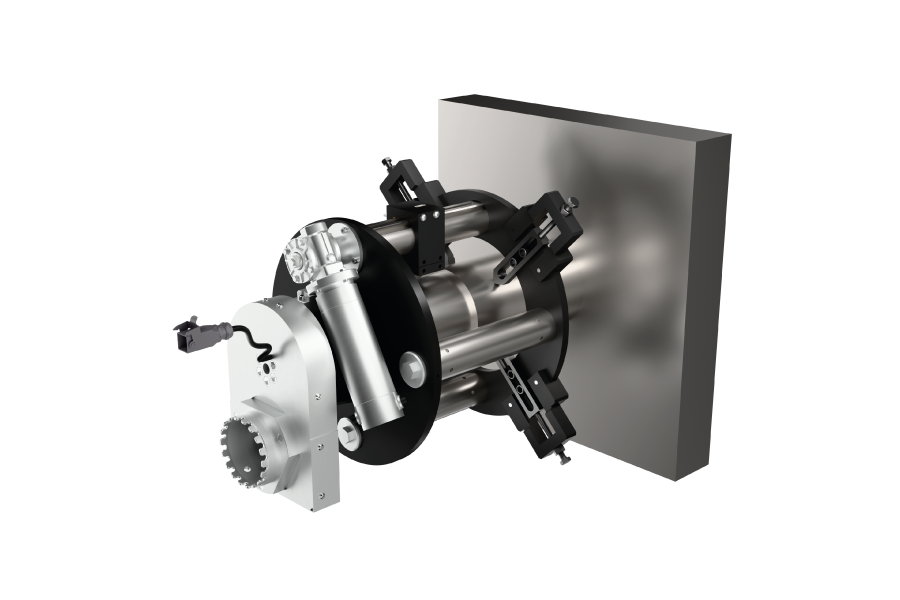

Large diameter kit

The large diameter kit is perfect for increasing the standard machining diameter up to a maximum of Ø 1700 mm. It is particularly suitable in all those sectors, such as naval, oil & gas, or wind power, guaranteeing stability and high performance even under heavy load. It is also designed to work even on difficult materials, minimising the risk of vibrations or inaccuracies, which can compromise machining quality.

Discover the right model for you

Facing Kit and the Creation of Seeger Seats

Flange facing is a fundamental process for obtaining flat and uniform surfaces, essential in many industrial applications. The facing kit is an innovative semi-automatic system, capable of removing material on faces perpendicular to the rotation axis of the machine. It also gives extremely precise results, in terms of flatness and surface finish, and guarantees perfect adhesion between components in contact, such as flanges.

The design of the components in this kit is aimed at optimising the technological process of orthogonal facing: the resulting high operating efficiency also has a significant effect in the reduction of tool wear.

Get more information on the facing kit now

Internal Threading Kit

Internal threading is a delicate process that requires precise equipment to ensure excellent quality. With the internal threading kit, Elsa has developed a solution that allows high-precision threading even in tight spaces. This kit is perfect for applications where threads need to be made quickly and accurately, without compromising the robustness or functionality of the machined part.

Find out how to improve your machining with our kit

Turning kit

External turning is a machining process in which a piece of metal material is rotated on an axis while a cutting tool is used to remove material from the outer surface of the workpiece. This process allows cylindrical, conical and other complex geometries to be obtained.

Elsa's turning kit is designed for a wide range of applications, from machining soft to hard metals, allowing flawless finishes and precise dimensions to be obtained while optimising machining times. Thanks to the quality of the materials used and the possibility to customise operations, the turning kit allows companies to increase their productivity.

Accessories: to improve efficiency and performance

Accessories are key components for enhancing machine functionality. Each is designed to simplify operators' jobs, improve efficiency and optimise overall performance.

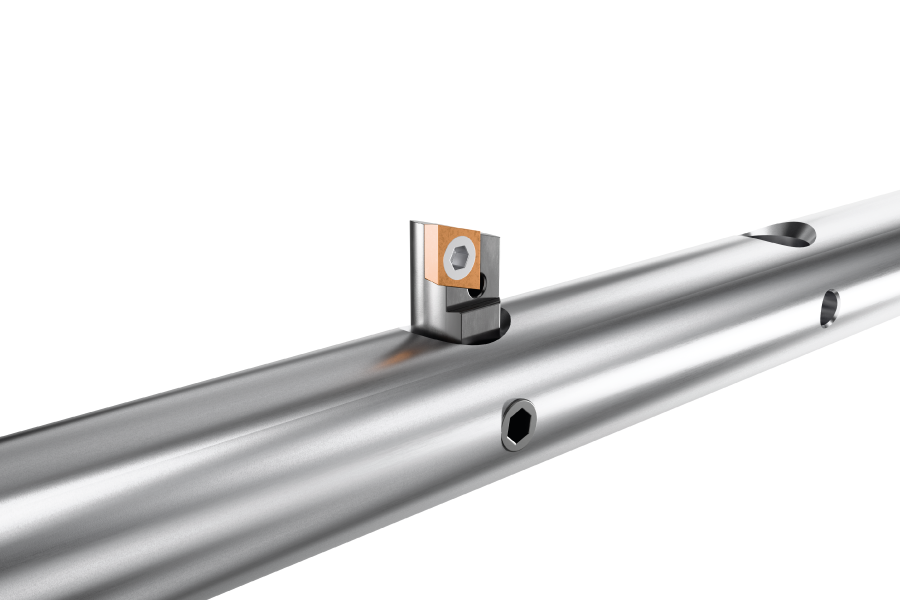

Couplings and tool holder shafts

Couplings and tool holder shafts are essential components for machine set-up as they enable machining operations to be carried out:

- line boring;

- overlay welding on long distances.

The couplings, internal and external, allow movement to be transmitted precisely and without loss of power, while the tool bars ensure that the tool remains stable throughout the machining cycle.

Both are designed to help improve machining quality by reducing vibration and unwanted movements.

Tool holders and internal supports

The tool holders and internal supports are designed to ensure the stability of the tools and the boring bar. A well-designed tool holder, such as the one offered by Elsa, allows you to:

- obtain a firm grip;

- improve machining precision.

Similarly, internal holders are indispensable for machining operations that require high stability during machining. They are used, for example, in the machining of cylindrical surfaces, and ensure the absorption of those stresses otherwise discharged onto the tool holder bar that would cause bending or other movements that could compromise the workpiece's machining quality.

Centring Cones

Centring cones are essential accessories for centring the tool holder bar: when used on reliable references, they are particularly suitable for ensuring correct positioning of the axis and thus quality machining. In precision machining, it is the accuracy of centring that is the crucial step in achieving excellent results.

Centring cones are a safe, practical and quick system, fundamental for obtaining very precise axis alignments of bores, bushings or, more generally, cylindrical surfaces.

They make it possible to minimise deviations in the positioning of the rotation axis of the tool bar and the consequent shape defects of the machined parts: avoiding damage or excessive tool wear.

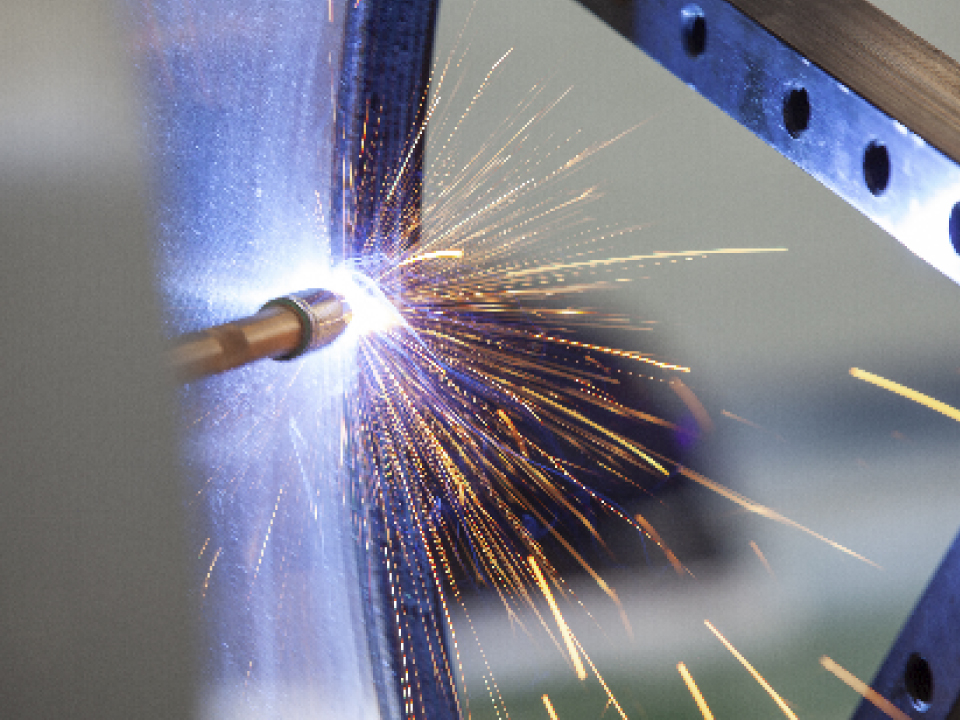

Welding Accessories

Welding accessories are essential to ensure an optimal hold of the material coating on both internal and external diameters. These accessories are designed to optimise welding processes, reducing processing time and improving the quality of the end product.

Extend the versatility of your Supercombinata

Elsa's Supercombinata portable line boring machines are ready to meet all machining needs. The complete standard equipment already covers the main needs, while the addition of extra kits and accessories offers the possibility to further customise operations, adapting them to the specific needs of each customer.

Invest in the right extra kits and accessories