Find out how the Elsa Facing Kit has revolutionised on-site machining, solving the complex requirements of industrial worksites.

The need for a flange facing kit

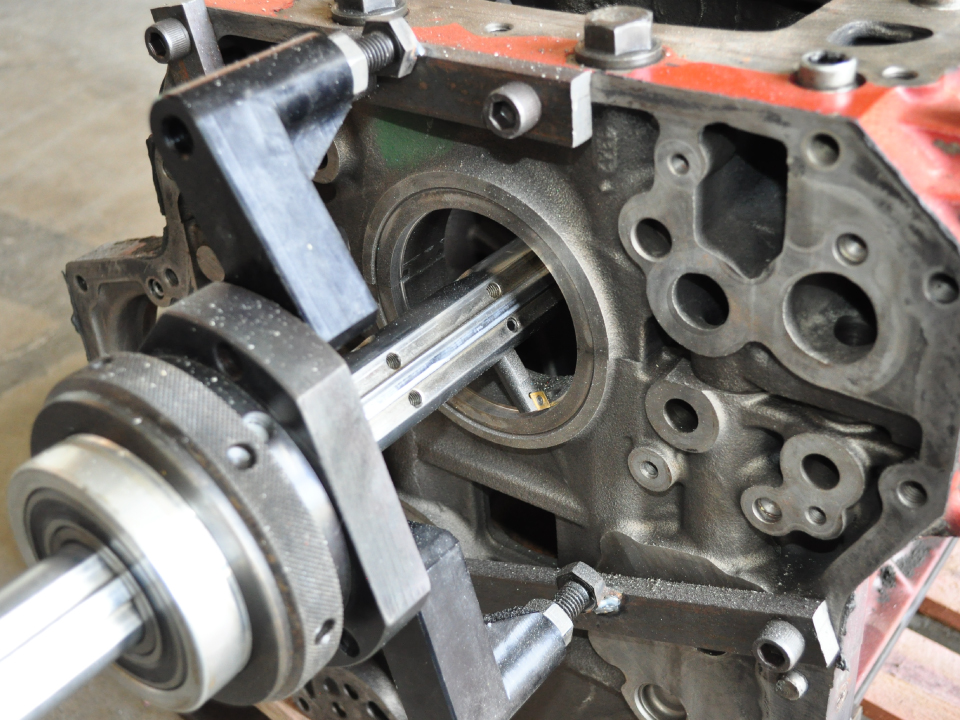

In an ever-changing world, Elsa constantly faces the challenge of responding effectively to the increasing customer demands. Our Supercombinata portable line boring machine, already established for its versatility and reliability, is now required by naval operators to perform complex machining operations such as:

-

flange facing of large pipes

-

machining of propeller shaft housings

These requirements from shipyards highlighted the need for an even more flexible and multifunctional solution. Elsa therefore embarked on a path of innovation that led to the creation of the Facing Kit, transforming the Supercombinata into a true mobile workshop, capable of carrying out even the most complex machining operations.

A successful experience: the challenge of a shipyard

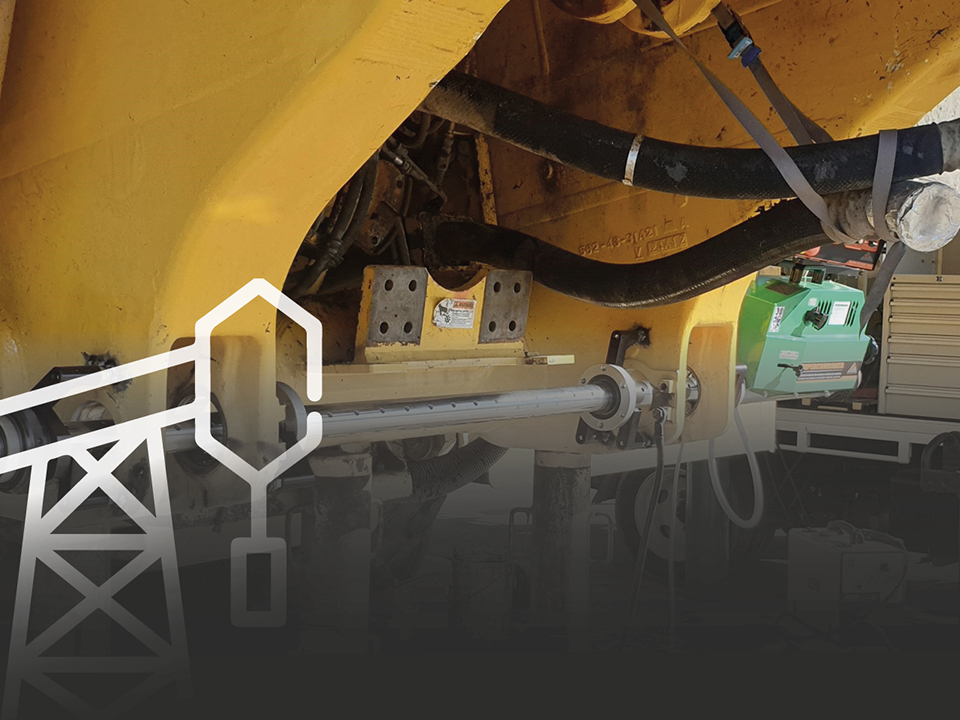

One of our customers, a major shipyard, contacted us with an urgent problem. They were using our Supercombinata for the repair of bushings and engine bearings on big ships, but this time the request was different: they needed to smooth the faces around the housing holes of a hatch's joint pins. After regenerating the holes, the surfaces had to be machined to ensure a perfect hatch fit.

Thanks to the versatility of the Supercombinata and the quick response of our engineering team, we provided a customised solution that solved the problem in record time. Our Facing Kit allowed the repair to be carried out directly on site, saving the customer time and costs for moving heavy equipment.

Elsa solution: the Facing Kit

In response to this and other requests, Elsa developed an innovative semi-automatic system capable of removing material on the faces, orthogonally to the machine's axis of rotation. Thus was born the first Kit for Facing Industrial Flanges, from which the KES series (Elsa Facing Kit) was derived. Today, this range of kits includes four models operating on different diameters, ensuring precision and reliability in any context.

Elsa: Innovations since 1997

Founded in 1997, Elsa has always aimed to anticipate market needs. From a small company dedicated to the earthmoving sector, it has evolved into a global brand thanks to the introduction of the Supercombinata, a revolutionary device that has transformed how maintenance is carried out.

Today, Elsa is a benchmark in the boring machines sector, embodying the values of Made in Italy: innovation, reliability and a constant search for excellence. Each product is the result of a vision that aims to make our customers' work more efficient and sustainable.

Why choose the Elsa Facing Kit

Our Facing Kit not only allows you to perform precise and fast on-site machining, but also to increase productivity and reduce downtime of your equipment. Thanks to the versatility and innovation that characterise our products, the kit can be adapted to several applications.

Find out more! Watch our 3D video to learn every detail of the Elsa Facing Kit: from facing diameters to advanced technical solutions.

A Global Community

In addition to the video tutorial, on YouTube and social media, you will find many other guides for assembling and using the kit, along with testimonials from satisfied customers from all over the world. Find out how our kit has improved efficiency in shipyards, industrial plants and many other applications. Join the Elsa community and share your experience!

This is just the beginning...

Elsa's ongoing innovation, represented by the Facing Kit, shows how a flexible and proactive approach can revolutionise many industrial sectors. Elsa will continue to respond to its customers' challenges, providing solutions that improve efficiency and add tangible value to maintenance and repair operations.

Download our complete catalogue to discover all of Elsa's solutions and improve your business now!

Take advantage of the 10% discount and improve your business!