The maintenance of heavy earthmoving and construction machinery is vital for safety and productivity. Learn about the importance of line boring works.

This type of machining is often underestimated, but it plays a key role in the reconditioning and repair of components subject to wear.

What is line boring and why is it important?

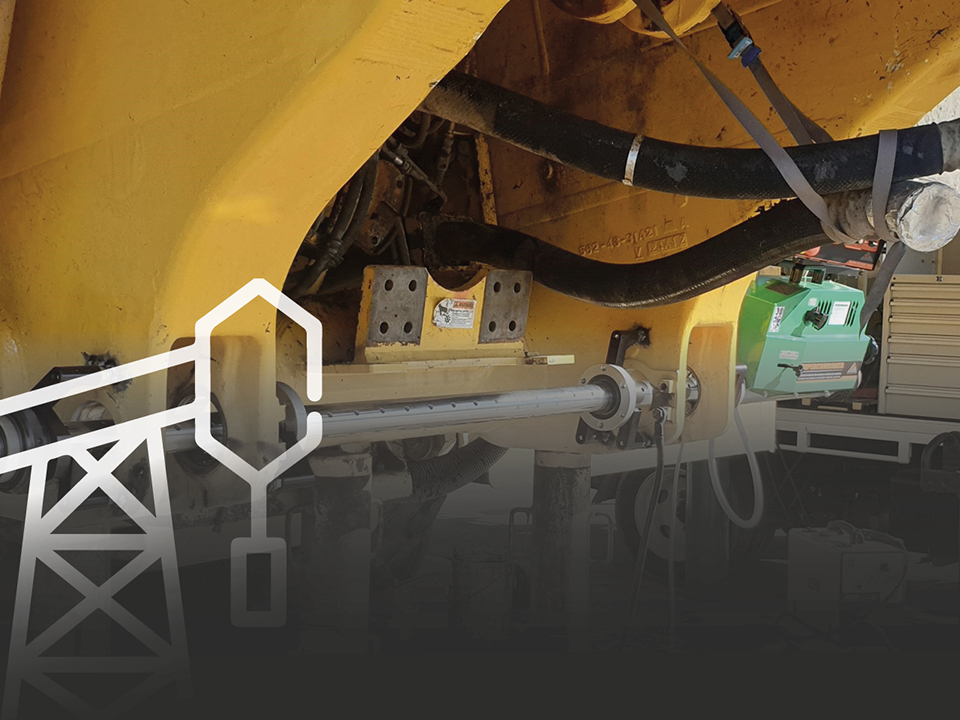

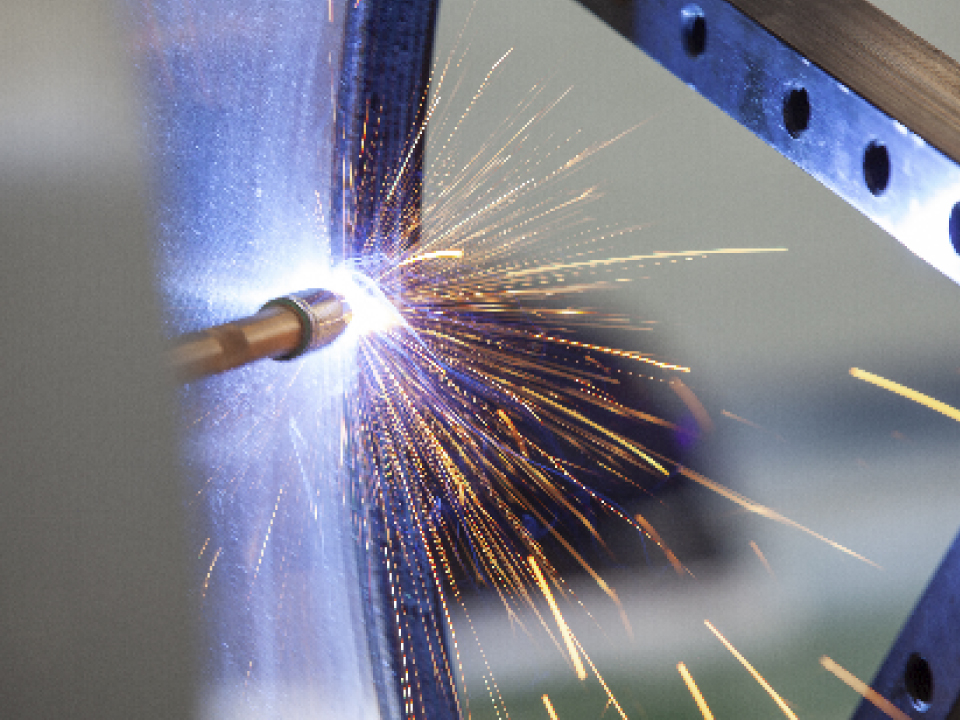

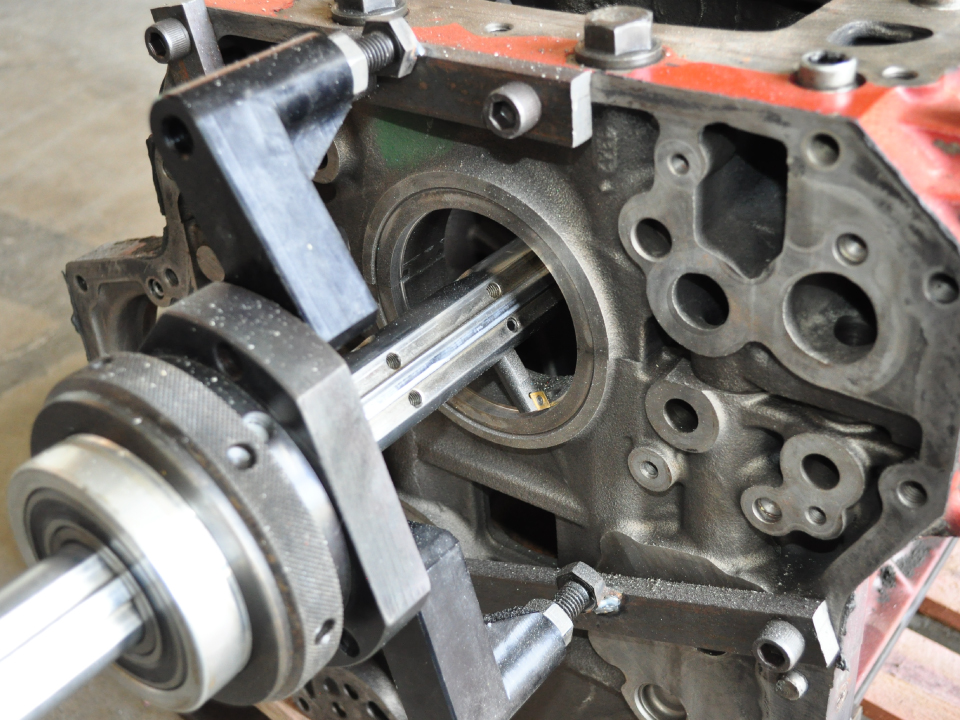

Line boring is a precision machining process that is used to repair the inner surfaces of the holes in mechanical components. During intensive use of heavy earthmoving and construction machinery, such as excavators or wheel loaders, wear and tear can cause deformations in pivots, bushings and bearings. This can lead to a malfunction of the entire mechanical system, compromising the operating capacity of the machinery.

Line boring is used to:

-

Restore the original dimensions of worn holes, ensuring precise and correct alignment of components.

-

Optimise operational efficiency by reducing friction between moving parts and improving structural stability.

-

Extend machine life by avoiding premature replacement of expensive components.

-

Reduce maintenance costs, as repairing damaged components is much cheaper than replacing them entirely.

What are the most common applications?

All of the following pivot points subject to wear and tear:

-

arms, joints and motors of large and small earth-moving machines

-

asphalt mixing equipment

-

lifting equipment, hydraulic cranes

-

agricultural and forestry machinery

-

concrete plants

-

tunneling equipment

The benefits of routine maintenance with line boring

Regular, preventive maintenance that includes line boring can make the difference between an efficient business and frequent downtime. Here are the main benefits of a thorough maintenance programme that includes line boring:

-

Prevention of unexpected breakdowns: Early maintenance reduces the risk of serious damage that can bring a machine to a complete standstill and interrupt work.

-

Reduction of operating costs: Planning maintenance activities avoids emergency repairs, which often result in higher costs and prolonged downtime.

-

Increased productivity: A well-maintained machine with bored and reconditioned components works more efficiently and with less unplanned downtime, ensuring operational continuity.

-

Work safety: A properly working machine reduces the risk of accidents due to malfunctions or defective parts, protecting both operators and workers on site.

The Elsa solution for line boring

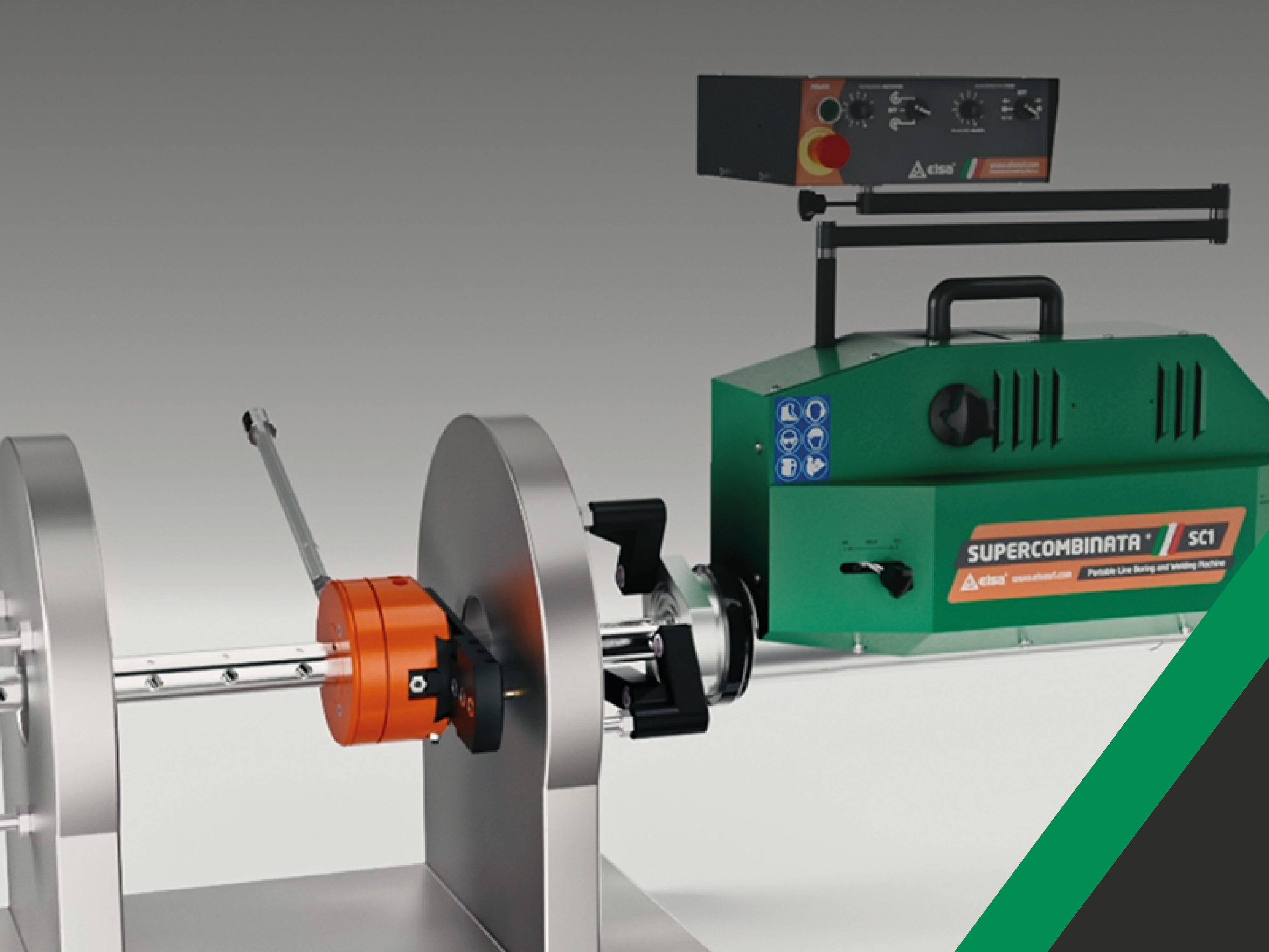

Elsa is a leading manufacturer of portable machine tools for the maintenance of heavy earthmoving and construction machinery, with a special focus on line boring. The Portable Line Boring Machine Supercombinata is an innovative solution for carrying out on-site line boring repairs without having to dismantle large components and significantly reducing operation times.

Elsa machines are designed to offer:

-

Maximum machining precision.

-

Versatility by being able to work on a wide range of diameters and components.

-

Ease of use, making line boring accessible even in challenging and narrow operational spaces.

-

Long-term reliability thanks to the use of durable materials and advanced technology.

Conclusion

Investing in the routine maintenance of heavy earthmoving and construction machinery, especially line boring, is a crucial step towards ensuring the competitiveness of your business. With Elsa's advanced solutions, you can keep your equipment up and running, reducing downtime and increasing productivity.