Overlay welding: how does it work, different kind of overlay welding, the benefits of this execution and how to work safely.

Who does overlay welding work?

Overlay welding is a generation method that is used in the repair or modification of existing components and in surface treatments. In every industrial sector there are parts subject to different wear phenomenon that require suitable maintenance of material addition. Overlay welding is used for maintenance in various sectors: steel, construction, agriculture, ceramic, oil and gas, paper, recycling, industry, chemical, food, rubber and plastic, wood and energy sector.

Different kind of overlay welding

Welding methods can be classified according to the method used in welding heat production and the way how the filling material is fed into the welding process.

The welding method used is selected based on the materials to be welded and the thickness of the material, on the required production efficiency and on the desired visual quality of the welding process. Among the most common processes for overlay welding there are: shielded metal arc welding, MIG/MAG, TIG and plasma welding.

The choice of the correct kind of overlay welding helps to save on the maintenance costs of the machinery and to increase its life cycle. Thanks to the overlay welding process, the maintenance cost of the machinery is significantly amortised. Generally, it is performed by coating a base metal with a more resistant metal layer. The most commonly used materials are stainless steel, a nickel-chromium-based alloy (known by its brand as Inconel) and a cobalt-chromium alloy (known by its trade name as Stellite).

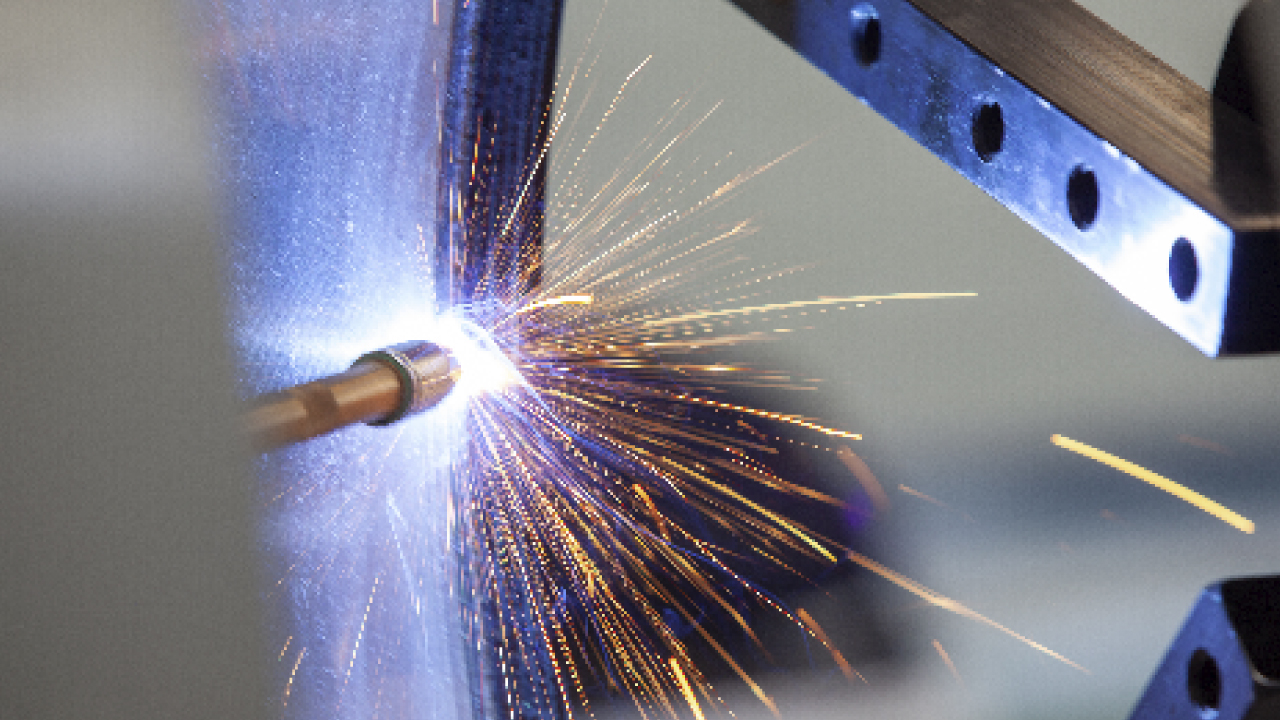

Safety in performing overlay welding

Overlay welding is a process that presents some risks for the safety of the operator. The most known is "the arc-eye", also known as "welder's flash". Looking at the welding arch with unprotected eyes can damage your eyesight permanently and even a short exposure can cause the burning of the eye surface. Ultraviolet and infrared radiation and visible elements, such as glowing spray, can damage eyes and burn unprotected skin.

Moreover, "welding fumes" are produced during processing, which may contain more than 40 different substances from the treated material, from the filler metals or surfaces such as paints and coatings. The welding fumes are dangerous to human health as tiny particles of smoke can enter deep into the lungs.

Since the welding process is potentially dangerous it is good to use and wear all the necessary protections, operating in absolute safety conditions.

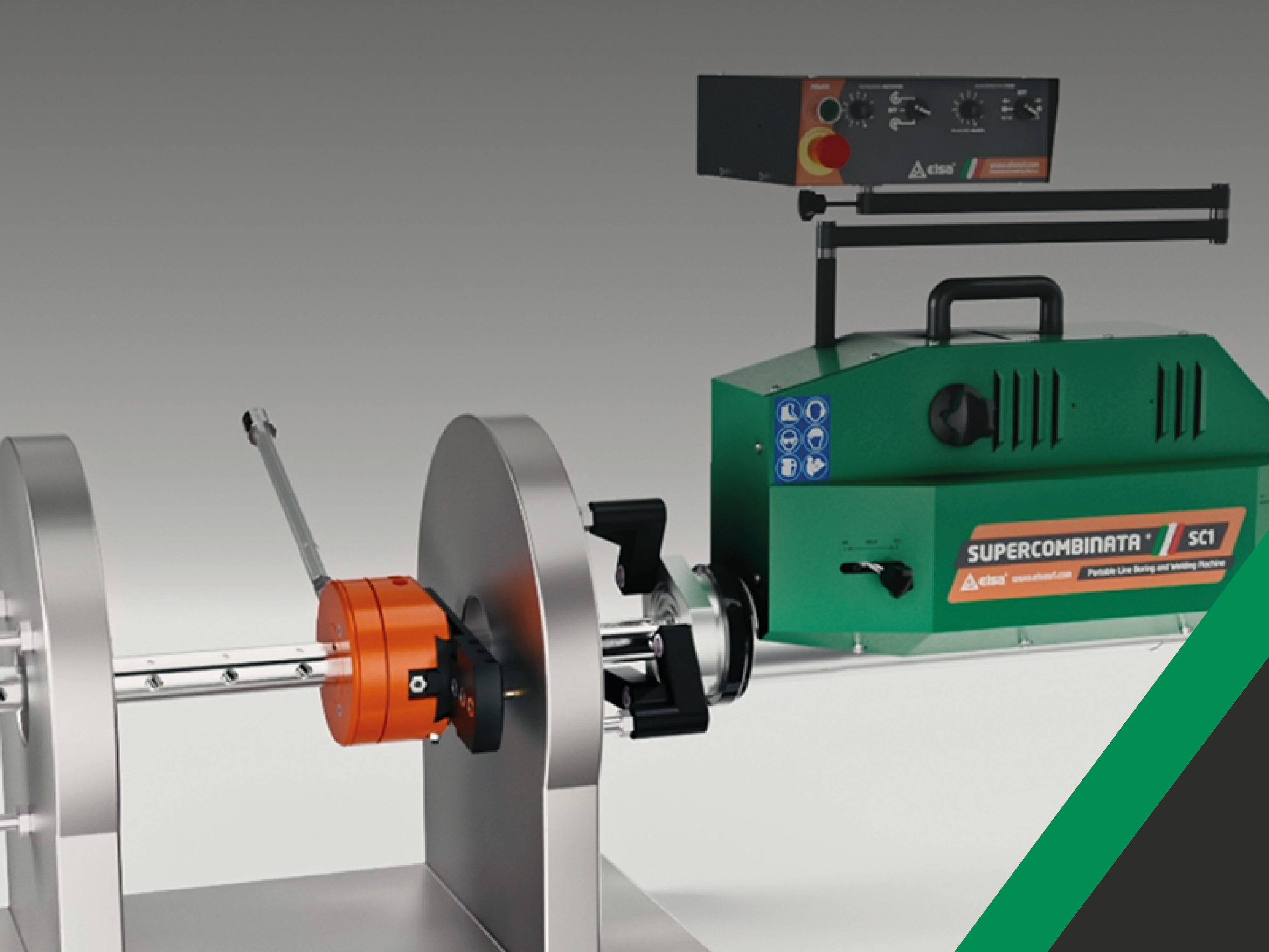

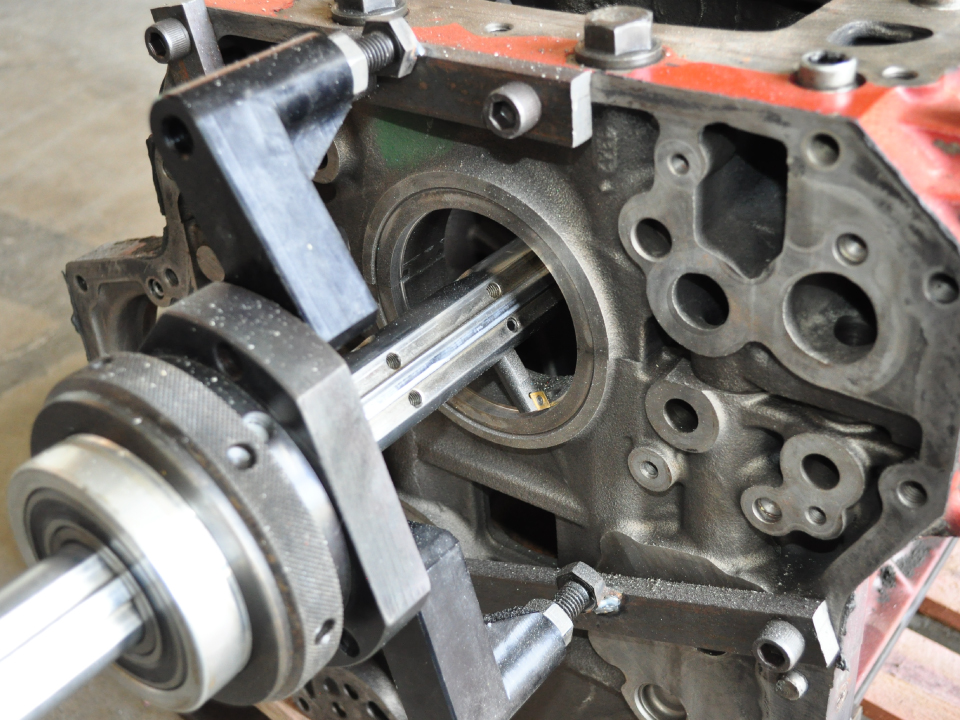

Overlay welding with the Supercombinata line boring machine

The line boring machine Supercombinata uses the MIG/MAG welding process, which is the most economical welding system and is suitable to withstand very high production rates, because in this type of welding the filler material consists of a wire that is fed continuously by the welding machine. Continuous wire welding involves, during the execution of the intervention, the introduction by the welding machine of an active or inert gas flow, which is needed to protect the molten material from oxidation.

The Supercombinata line boring machines are able to carry out continuous welding with variable pitch through a telescopic torch with swivel joint extendable up to 2100 mm. Our welding torch with EURO connection is compatible with MIG/MAG 250 A wire welding machines.

Automatic overlay welding

In welding mode, rotation and feed are mechanically combined, so ensuring high quality results (uniform weld seams). In welding mode, the Supercombinata carries out the process of overlay welding automatically, eliminating any errors by the operator.

Advantages of overlay welding

The automatic overlay welding process, achievable with the Supercombinata, is advantageous in terms of quality, efficiency and repeatability. The automatic execution can be carried out not in close contact with the machine, thanks to the remote-control button, thus preserving the operator from harmful fumes and heat. The Supercombinata ELSA allows machining in hard-to-reach areas and in other challenging situations for manual welding, and in conclusion it allows to perform quality welding and saves time and costs.

Visit our website and discover more

Bonifacio Monti, Mechanical Engineer