Find out how Henning Müller used careful analyses and targeted operations to refurbish an excavator with the portable line boring machine Supercombinata.

The Users

Henning Müller Sondermaschinenbau GmbH, a German company founded in 1989 by Mr and Mrs Müller and now managed by their children Steffen and Ramona, is a reference in the mechanical repair industry with over 30 years of experience.

Since 2010, the company has specialised in on-site machining for the repair of holes, shafts and other mechanical wear parts.

It has been an official Elsa partner for the German market since 2024.

The challenge to be mastered

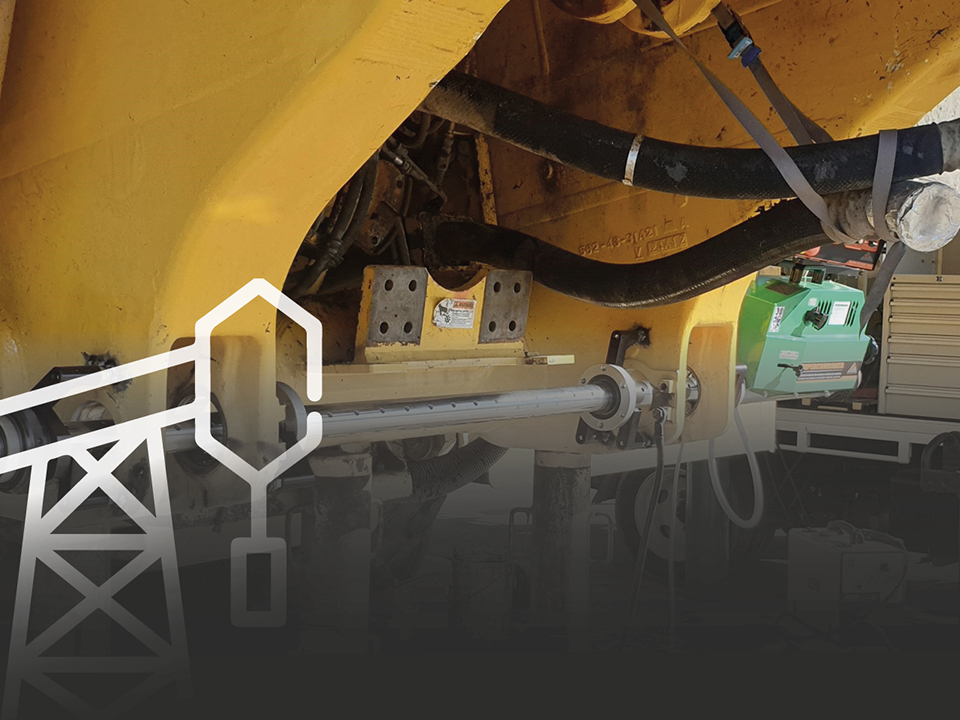

Henning Müller was faced with a major challenge: repairing the bucket of a Liebherr 976 excavator that had been severely damaged by intensive use in a steel plant. The bent and dismantled bucket not only had to be straightened, but the bearing seats had also to be precisely realigned.

From the challenge to the solution

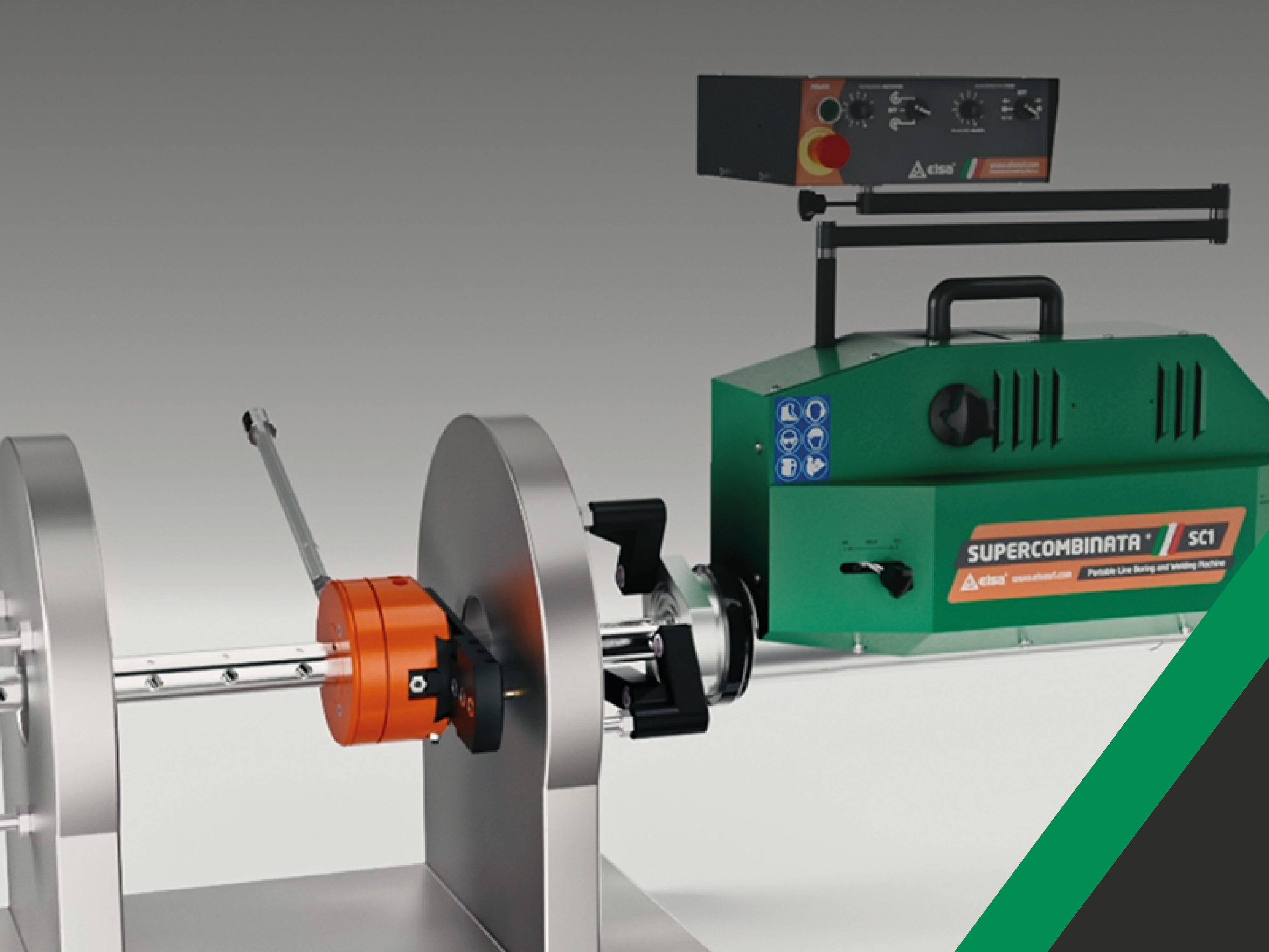

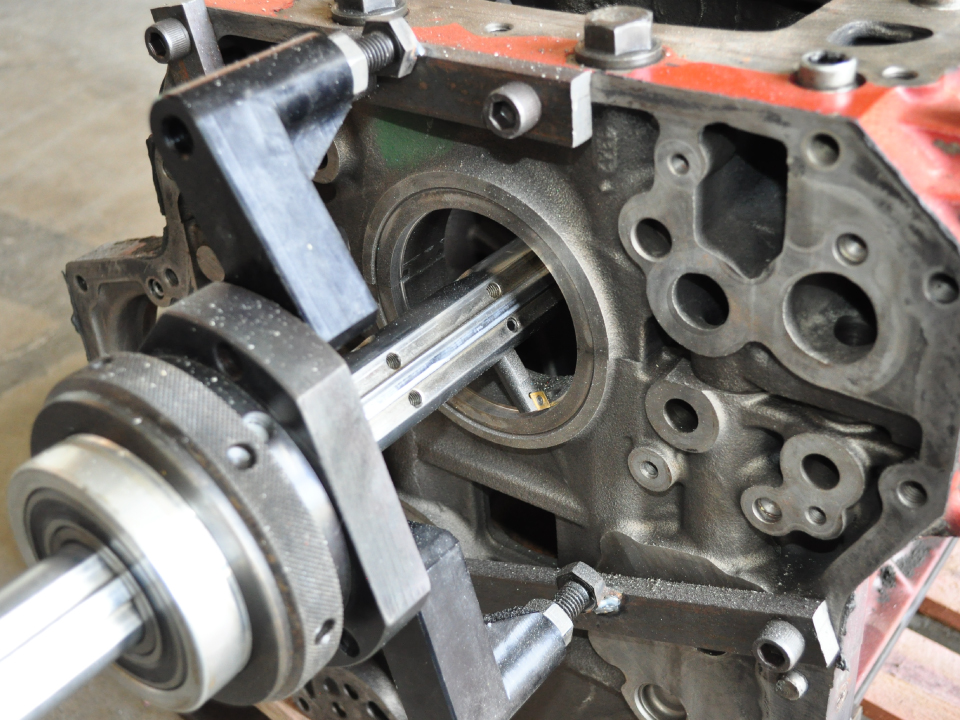

The repair of such a damaged excavator bucket required a special approach and the use of state-of-the-art equipment. After carefully evaluating the various options, Henning Müller decided in favour of our portable line boring machine Supercombinata SC3. This machine, thanks to its capability to process big workpieces and its precision, has turned out to be the ideal tool for carrying out the repair.

Repair method

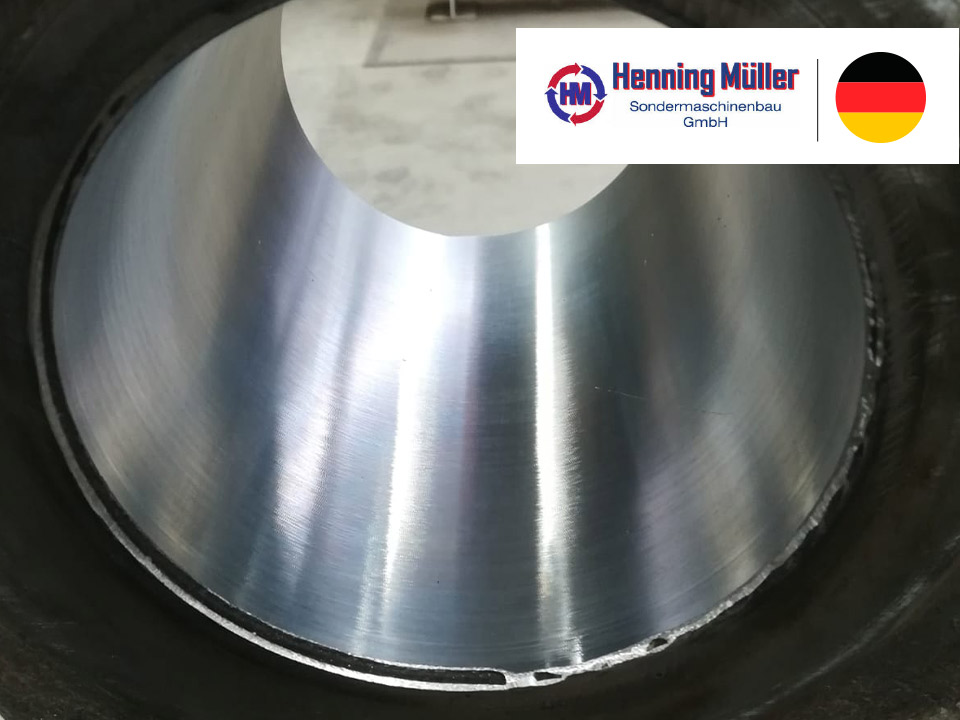

The repair process began with the precise realignment of the boring shaft in the original bores. Using high-precision measuring instruments, the technicians restored the coaxiality of the bores. Next, they carried out the following:

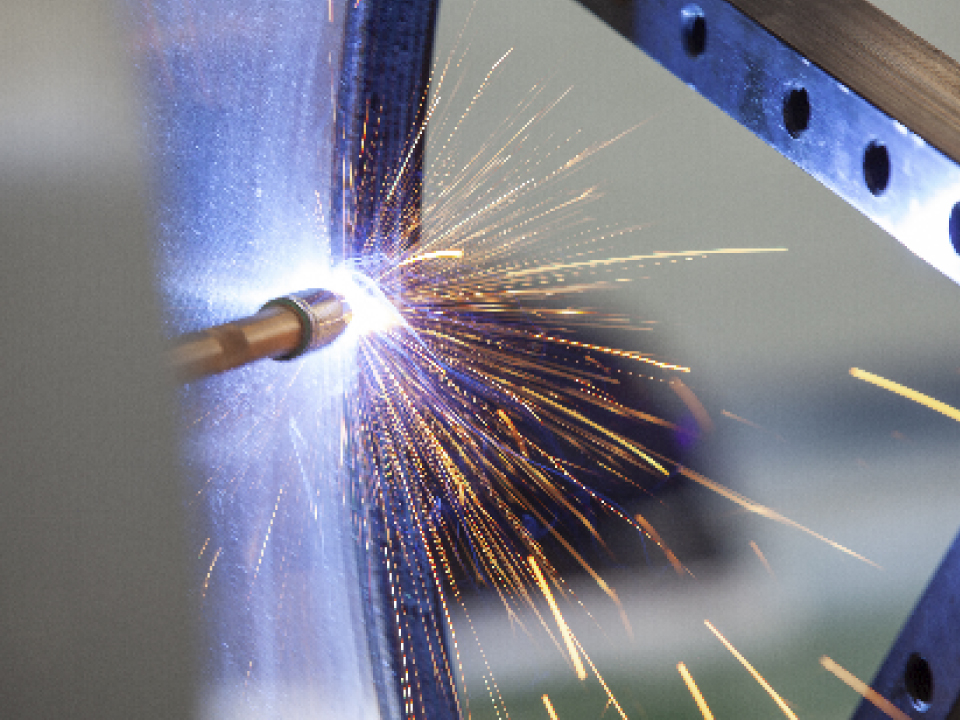

- Pre-spindling to prepare the bores for welding.

- Welding and final finishing, restoring the original diameter of the holes with a tolerance of 0.03 mm.

This method made it possible to reuse original components, reducing costs and waste.

Exceeding expectations: the impact of the Supercombinata

The versatility of the Supercombinata SC3 made it possible to use it quickly and efficiently directly on the customer's construction site. Unlike other machines in Henning Müller's fleet, the SC3 was developed specifically for on-site use to ensure maximum flexibility and precision even outside the workshop. This feature, combined with its performance, enabled Henning Müller to successfully tackle the bucket refurbishment.

The advantages compared to a conventional repair

The repair of the Liebherr 976 excavator bucket was successfully completed in 38.5 hours. During this time, 10 holes with a diameter of 110 mm were re-drilled in 3 axes, ensuring perfect precision and concentricity.

<< The decision to use the Supercombinata Elsa SC3 proved to be strategically correct. Unlike a conventional repair, which would have required the holes to be filled, compromising the stability of the bearings, the Elsa boring machine allowed us to work directly on the damaged holes, maintaining structural integrity. Furthermore, the ability to work directly on site eliminated the need for time-consuming and costly transportation, minimising downtime.

This solution offered significant benefits in terms of cost and lead time. In fact, the overall costs were around 66% lower compared to a conventional repair>>, said Henning Müller after the work was completed.

Obtained Results

Henning Müller has successfully completed the repair of a large bucket belonging to an 86-tonne Liebherr 976 excavator with a capacity of 3.5 m³.

Finally, Henning Müller recalibrated the 120 mm and 90 mm bores to ensure millimetre accuracy and thus restore the perfect functionality of his customer's equipment.

Find out how our boring machines can improve your productivity. Contact us for more information!