Find out how Elsa's Supercombinata portable line boring machines solve maintenance problems in the rail industry. See case study on Fleet Engineering Services Ltd.

The main problems in railway maintenance

In the railway industry, any maintenance work must be quick, precise and compatible with tight mechanical tolerances. The most common problems include:

- Wear of pin and bushing

- Seats Ovalisation of axle housings

- Need for welding and re-machining

- Long stops due to disassembly of components

- Operational difficulties in confined spaces

These factors weigh heavily on time, cost and safety. Traditional techniques require parts to be completely disassembled and transported to the workshop, increasing downtime and overall costs. The railway sector therefore needs mobile, flexible and highly precise solutions.

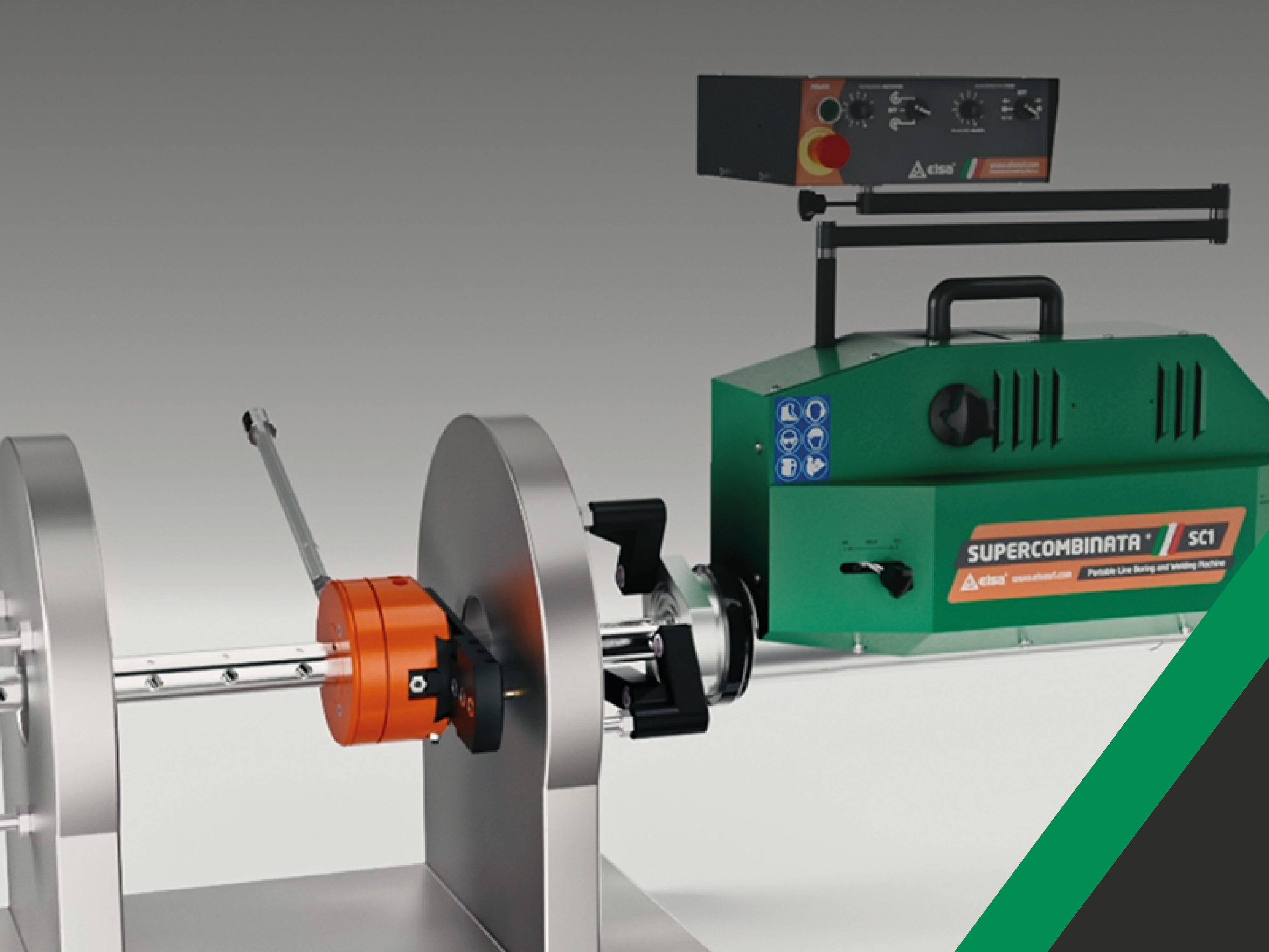

Elsa's solution: the Supercombinata portable line boring machine

Elsa, a leading Italian company in on-site machining solutions, has developed the Supercombinata range, a series of multifunctional portable boring machines that are ideal for tackling the critical issues of repairs in the railway sector.

With the Supercombinata it is possible to:

- Carry out precision boring directly on site

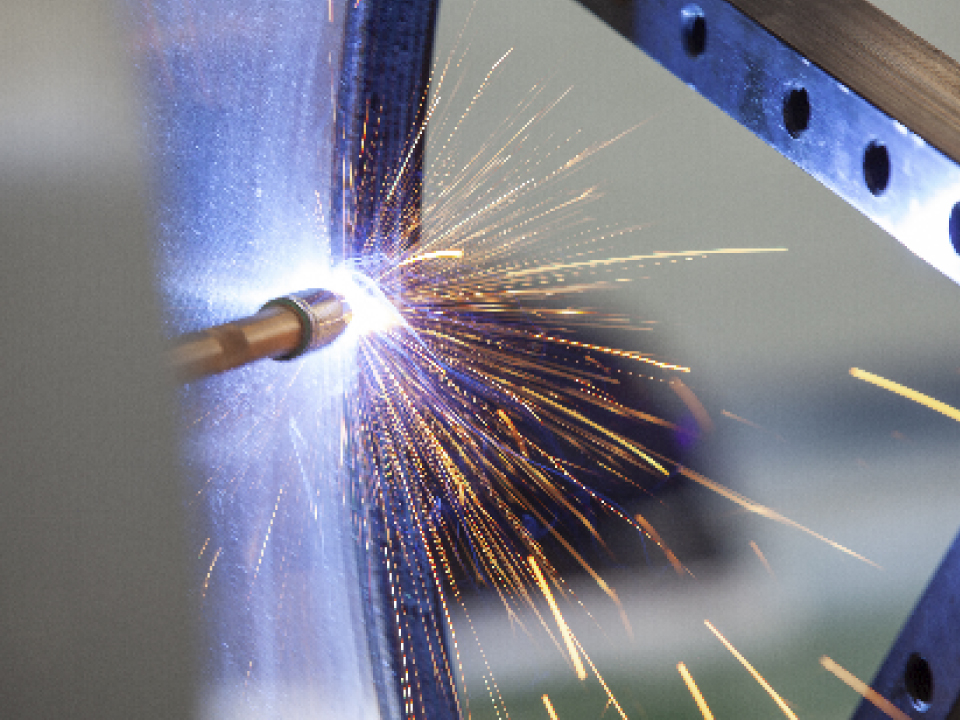

- Carry out welding operations

- Operate in restricted and unequipped environments

- Avoid transport to the workshop

- Drastically reduce maintenance time and costs

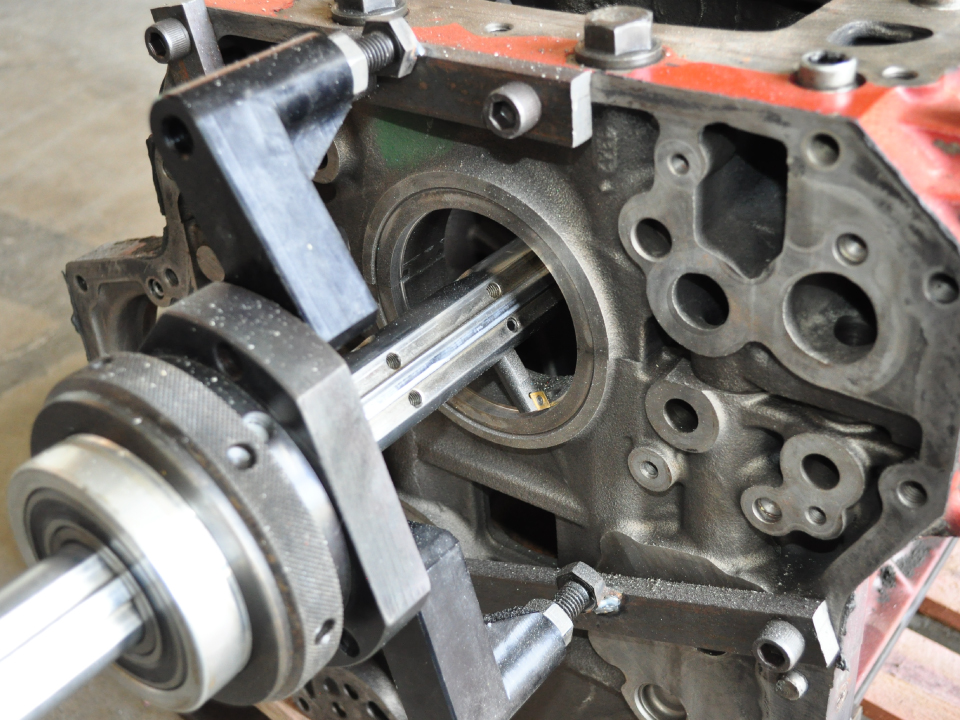

Supercombinata portable line boring machines are lightweight, versatile and easily transportable. Operators can perform complex machining with centesimal tolerances, even on historic trains or special maintenance vehicles.

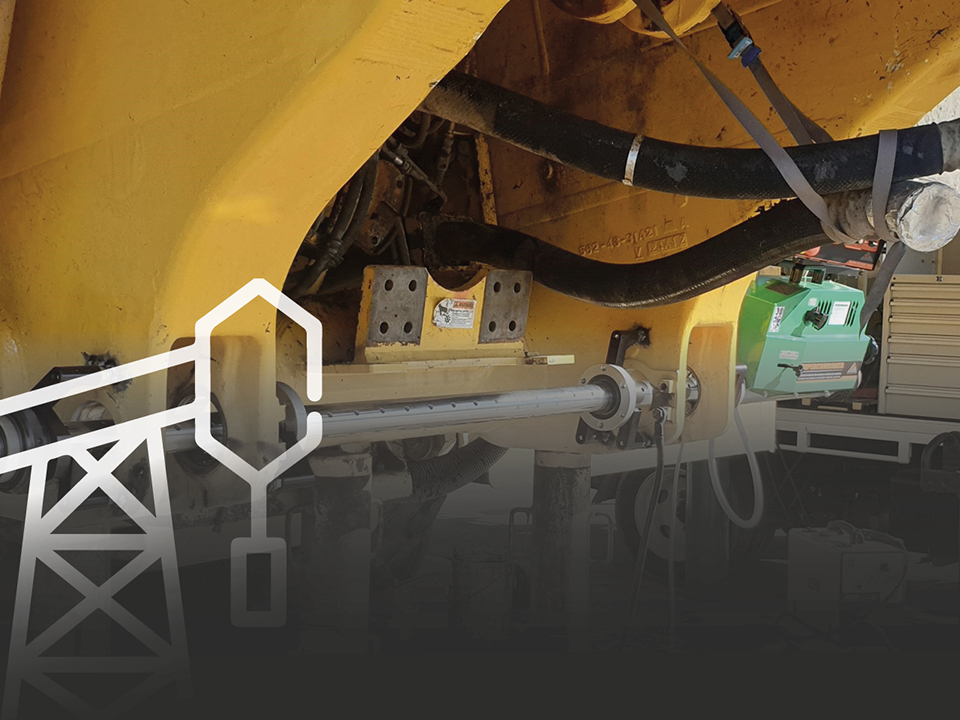

Case Study: Fleet Engineering Services and the Class 5600 locomotive

A concrete example of how Elsa solves real railway problems is given by Fleet Engineering Services Ltd, a UK company that some years ago carried out a repair job on a Class 5600 steam locomotive, built in 1925 at the Swindon works.

Operating in South Wales until its retirement in 1963, it was stationed at the Woodham scrap yard in Barry. It was restored in 1986 and hauled its first passenger train in 2006.

Technical intervention: restoring valve guides

During the restoration, precise machining of the time-worn valve guides became necessary. Fleet Engineering Services Ltd used Elsa's Supercombinata line portable boring machine to carry out the job directly on the locomotive, without removing the engine or transferring the part to the workshop.

The operation made it possible to:

-

Restore full valve functionality

-

Respect the historicity of the vehicle

-

Reduce machining time

-

Avoid costly transportation or replacements

This operation confirmed the effectiveness of Elsa technology even on historic vehicles, where accuracy and precision are crucial.

Real benefits for railway operators and maintenance companies

Elsa portable line boring machines offer concrete benefits to workshops and rolling stock operators:

- Less downtime

- Cut operating costs

- On-site machining without disassembly

- High precision and reliability

- Compatibility with modern and historic vehicles

- Technical support and training

Why Elsa is the best partner for railway maintenance

With more than 25 years of experience, a global network of customers and a state-of-the-art technical department, Elsa stands out as a strategic partner for railway maintenance, whether for passenger trains, freight trains, special vehicles or historic locomotives, Elsa provides:

- Turnkey solutions

- Reliable and durable machines

- Customised technical

- training On-site training

- Ongoing pre- and after-sales support

Contact us

Elsa Srl is also ready to support your company in on-site railway maintenance.