Supercombinata portable line boring machines are crucial for the maintenance and revamping of hydropower plants, guaranteeing efficiency and precision.

Hydropower: a key renewable resource

- Hydropower is one of the most reliable and sustainable renewable sources.

- It is the clean source that produces the most electricity in the world.

- It has a low environmental impact compared to other energy production technologies.

The importance of maintenance in hydropower plants

To ensure the long-term efficiency of hydropower plants, thorough and constant maintenance is necessary. Advanced tools are needed to support:

- routine maintenance

- on-site repair

- activities revamping of hydropower plants

Hydropower plants are composed of many mechanical components that are subject to continuous and cyclical stress: turbines, distributors, sluice gates, shafts, bearings and guides. The natural wear of components such as bushings, bearings, joints and mechanical seats can affect alignment, cause vibrations, noise or drops in efficiency in energy production.

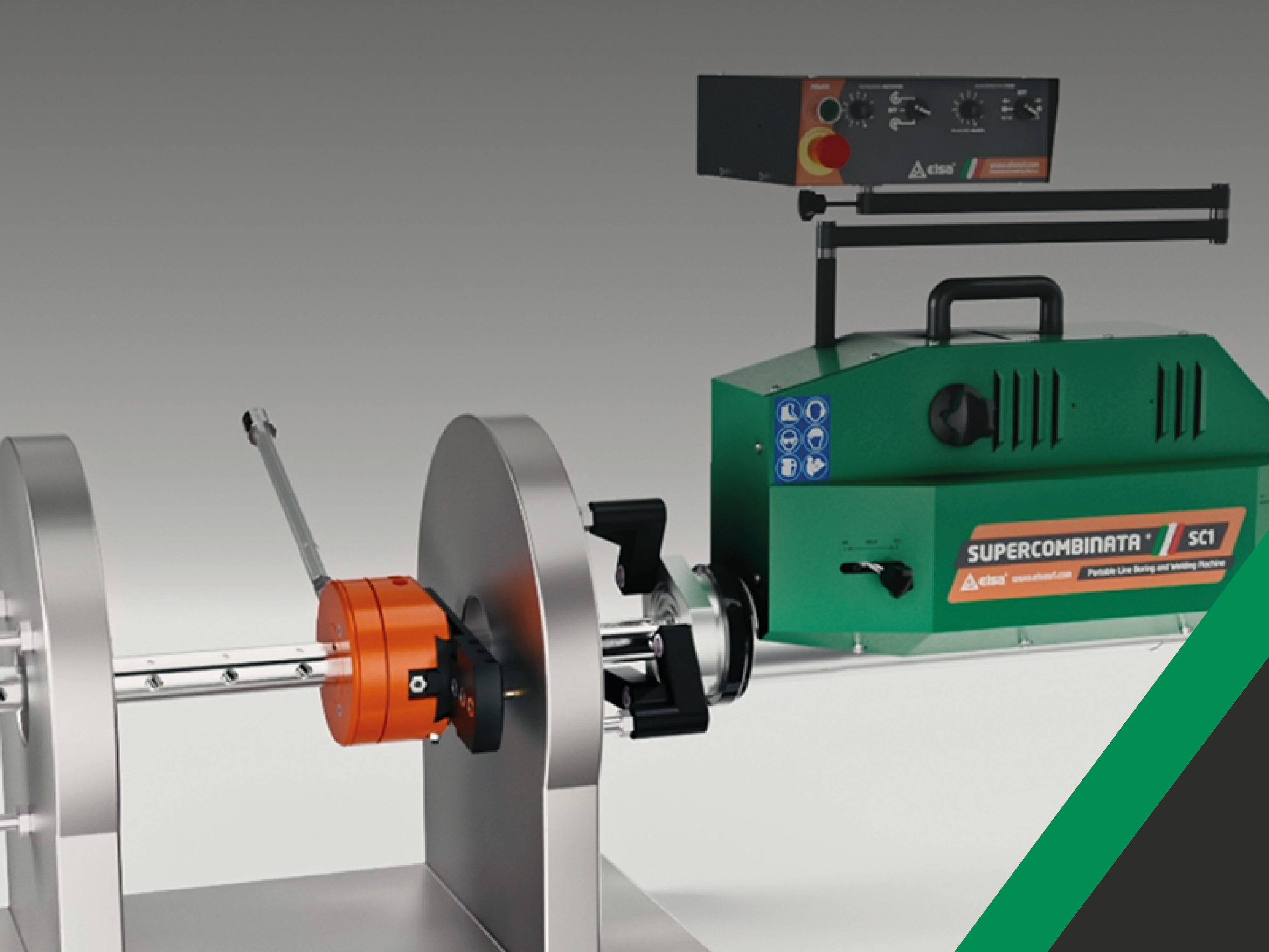

Supercombinata ELSA: portable excellence for the energy sector

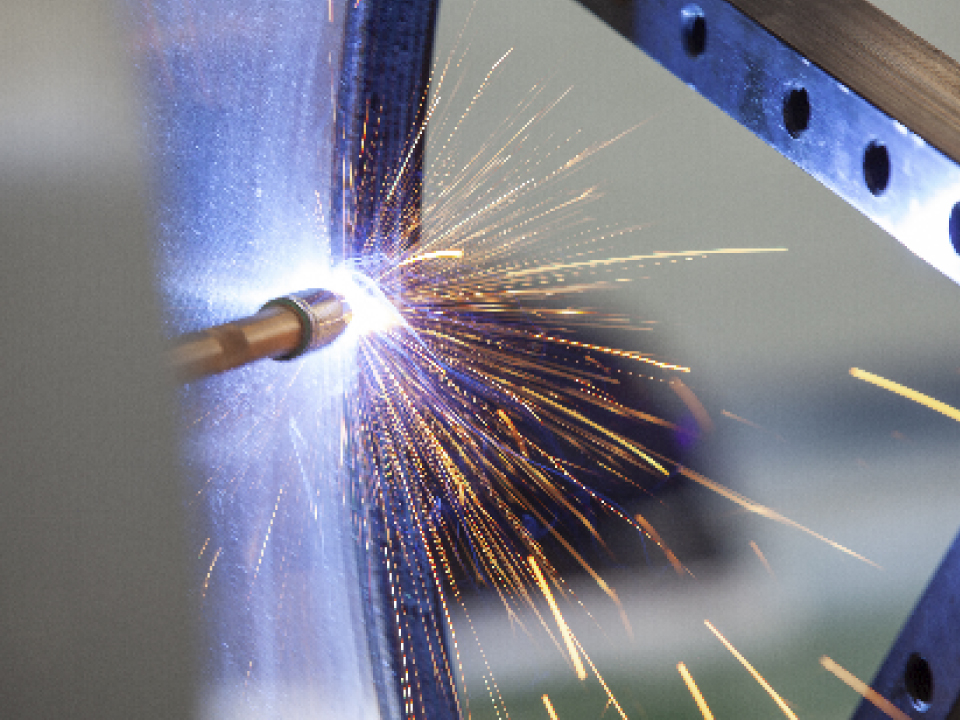

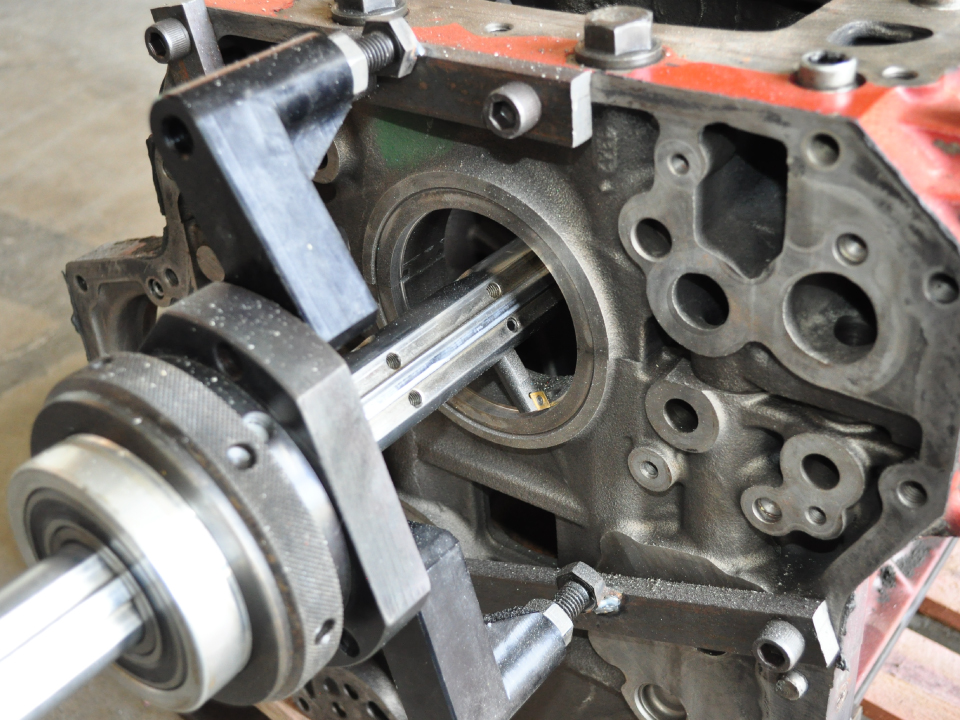

Supercombinata machines are multifunctional portable line boring machines, designed by Elsa to offer flexible, robust and reliable solutions in the most demanding industrial environments. They are perfect for use in hydroelectric power plants, during both routine and extraordinary maintenance activities.

The main processes that can be performed:

- Axial line boring: Ideal for reconditioning worn cylindrical holes, such as those designed to accommodate pins, bearings, bushings or alignments between rotating parts. Typical is the case of the arm housings of moving blades in Kaplan turbines, where wear can cause excessive play or misalignment.

- Line boring of coupled seats: it is often necessary to bore two aligned holes located on distant structures such as, for example, the supports of a butterfly valve or a supporting structure. The Supercombinata portable line boring machine allows perfect geometric alignment between the two holes, thus eliminating misalignment and play.

- Line boring of joints and bushings on gates: in many hydropower plants, gates (discharge or control) are subject to slow but constant movements. Bushings or hinge seats tend to ovalise. With the Supercombinata portable line borer, it is possible to repair them in a focused way, restoring the original geometry.

- Turning and facing: the Supercombinata portable line boring machine also allows machining on circular or flat surfaces, such as sealing flanges or bearing surfaces of mechanical components.

- Preparation for inserting bushings: when revamping, it is often useful to over-bore a worn hole to install a new bushing, creating a smooth and perfectly cylindrical surface. The Supercombinata Portable Line Boring Machine ensures a high quality finish, ready to fit.

Using Elsa portable machine tools provides several practical advantages right from the start:

- Reduced downtime: working directly on the plant means less downtime, avoiding complex dismantling and limiting logistical costs.

- Precision and reliability: the fine adjustment of the feed rate of the Supercombinata portable line boring machines, as it is independent of rotation speed, allows high quality finishes to be achieved and tight tolerances to be respected.

- Application versatility: with a single machine it is possible to machine holes from 22 mm up to 1700 mm, covering all the typical requirements of the hydropower sector, from micro power stations to large dams.

- Compactness and ease of use: thanks to its industry-designed structure and light weight, the Supercombinata portable line boring machine can be easily carried and assembled even in areas that are difficult to access.

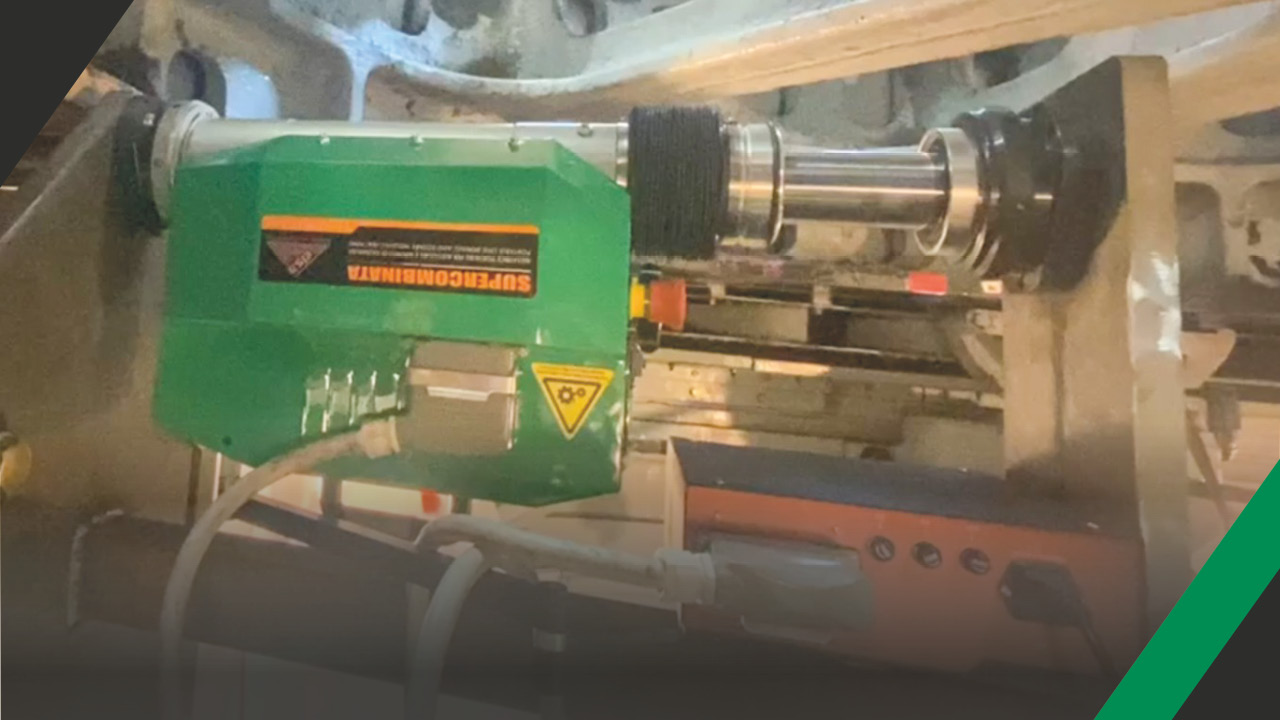

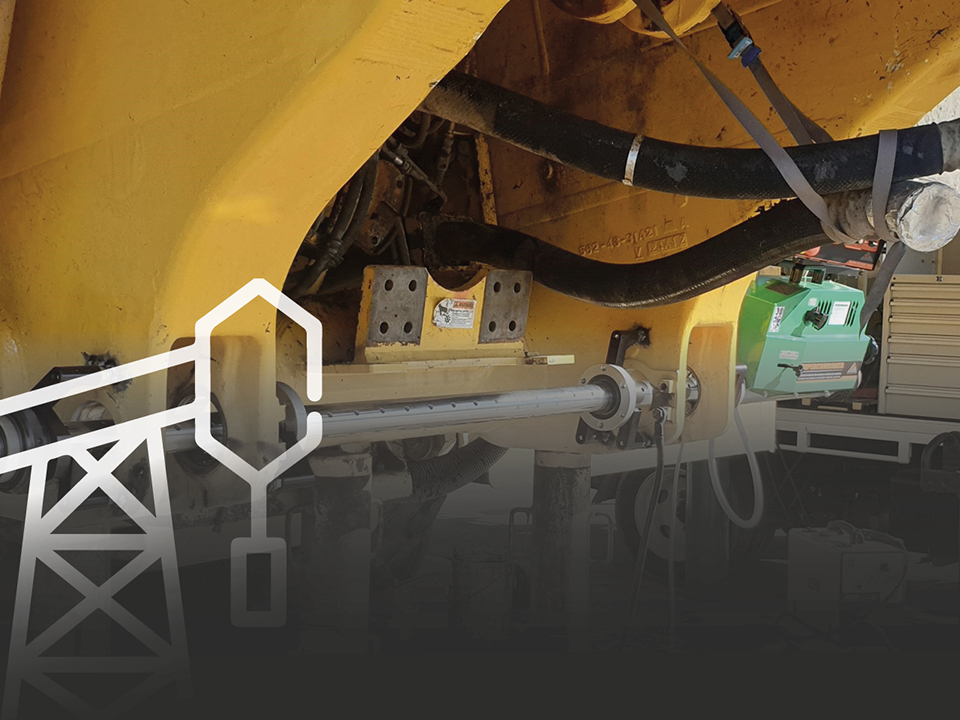

The Supercombinata in action: real applications in the industry

Supercombinata portable line boring machines are already being used in different power plants in Europe and around the world for jobs on:

- Mobile blade pin seats;

- Bushings and joints of segmented sluice gates;

- Flanges and guides of shut-off valves;

- Vertical turbine shaft bearings;

- Cylindrical seats of hydraulic distributors.

In many cases, machining can be completed in just a few hours, minimising plant downtime and without the need for lifting equipment or external workshops.

Why you should choose Elsa

For over 25 years, ELSA has been designing and manufacturing portable line boring machines, entirely Made in Italy, with consolidated know-how and an extended technical support network. Each Supercombinata is the result of advanced mechanical research, design and constant feedback from operators in the field.

Choosing the Supercombinata means choosing:

- Industrial-grade build quality;

- Reliability in demanding environments;

- Direct technical support and training.

Conclusions

In the hydropower sector, the reliability of plants depends strictly on the mechanical precision of their components.

To ensure operational continuity and high performance, it is necessary to have advanced tools for maintenance.

Elsa Supercombinata line boring machines guarantee reliability, rapidity and precision.

They are the strategic investment to extend the life of hydropower plants and improve overall performance.

Contact us to find out which Supercombinata model best suits your plant's needs.