Discover 4 common mistakes in the maintenance of industrial, agricultural and earthmoving machinery. Avoid them with Elsa's portable line boring machines

Maintenance of industrial, agricultural and earthmoving machinery is a crucial factor for operational efficiency and profitability. Keeping equipment in top operating condition not only drastically reduces repair costs, but is essential for preventing downtime, which can cripple productivity. In spite of its fundamental importance, mistakes in maintenance are made in daily practice that can lead to more or less extensive damage and therefore to unexpected expenses.

We will therefore analyse the 4 most common errors in heavy machinery maintenance and how Elsa's solutions are an effective way to avoid them.

1 - Ignoring preventive maintenance

Neglecting preventive maintenance can lead to:

- sudden breakdowns;

- costly repairs;

- unplanned downtime;

- a negative impact on productivity.

What Elsa recommends

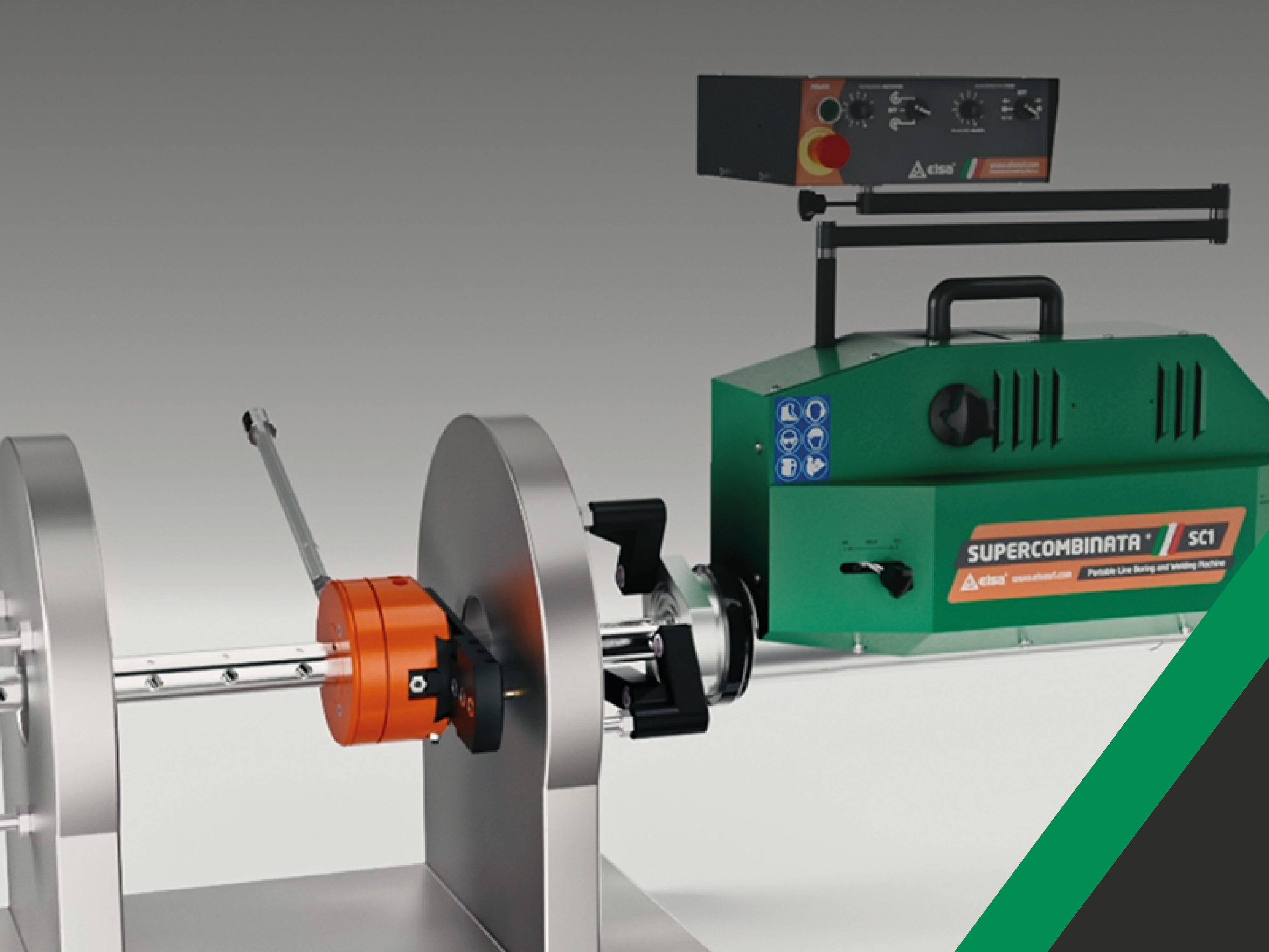

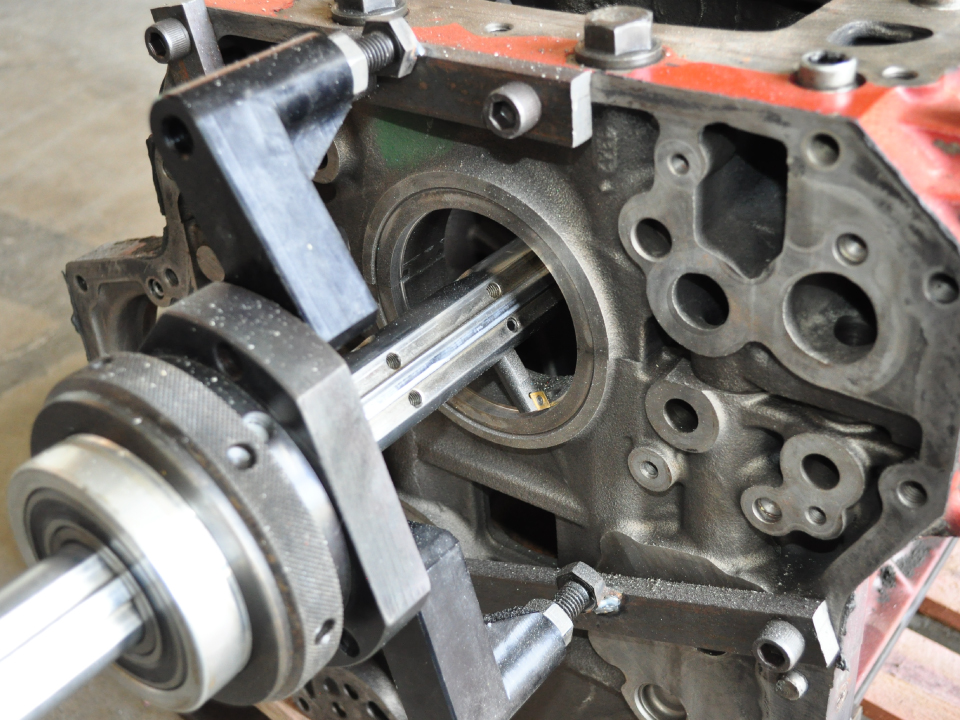

Supercombinata portable line boring machines are designed to make this practice simple and efficient. The ability to carry out maintenance work directly on site, without disassembling and transporting components, drastically reduces the time needed to inspect and repair worn bores. Elsa's portable machine tools guarantee fast and efficient operation, preventing future damage, minimising downtime and extending the life of your equipment.

2 - Neglecting the importance of diagnostics

Relying only on visual inspections is not enough to prevent sudden and irreparable failures. Advanced diagnostics are essential for effective machine maintenance. While we specialise in portable machine tools for machining work, we understand the importance of monitoring the general condition of machinery.

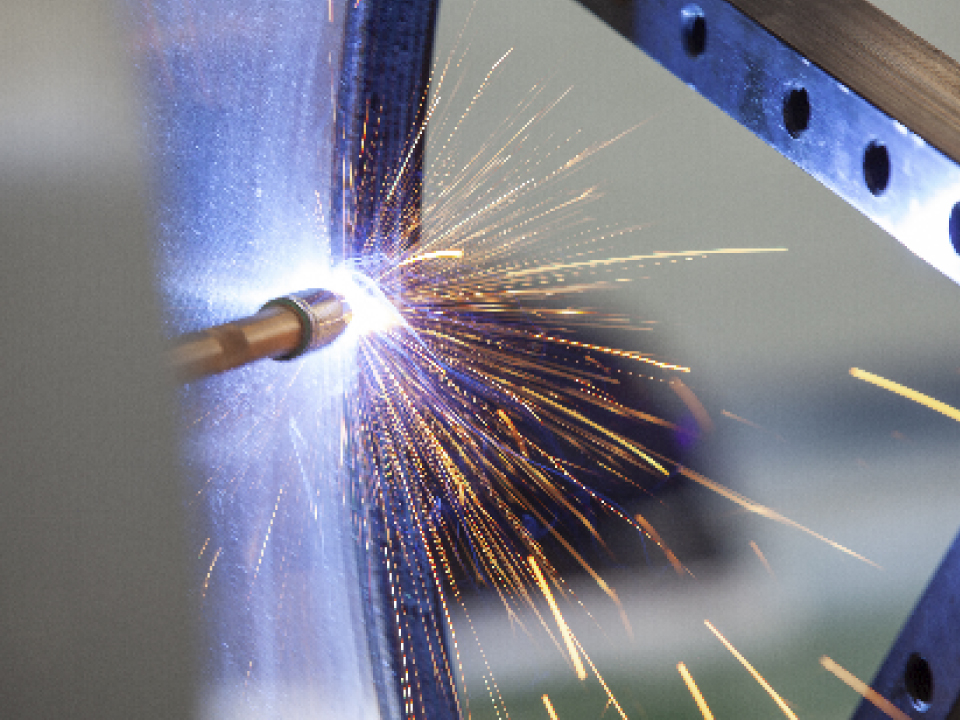

A maintenance plan that includes diagnostic tools allows us to detect hidden problems, such as cracks, and avoid costly breakdowns. When diagnostics detect the need for action, our on-site machine tools ensure fast and efficient intervention, reducing downtime and improving the reliability of repaired equipment.

What we suggest:

We suggest that our customers and staff carry out:

- Predictive diagnostics: continuous monitoring of the overall condition of machinery;

- Use of diagnostic tools: identification of hidden problems;

- On-site repair: fast and effective intervention for worn components, reducing downtime;

- Maintenance plan: organise and manage preventive checks to ensure long-term reliability.

3 - Not using original spare parts

The use of non-original spare parts for industrial machinery is an issue that goes far beyond mere cost savings. This choice can seriously compromise the operational safety, durability and efficiency of construction machinery, quickly turning into a much higher cost.

It is often tempting to choose cheaper alternatives, but it is crucial to understand that, in the context of construction equipment, original spare parts are not an extra cost, but a strategic investment in the longevity and safety of the machinery. They are designed with precise tolerances and specific materials to work in perfect harmony with the entire machine system.

Elsa, for example, is committed to supplying only high-quality original spare parts for its products. These parts are developed and tested to ensure that maintenance and repair work, even those carried out directly on the construction site, are perfect.

Relying on certified components, such as those offered by Elsa, ensures total compatibility with the vehicle, guaranteeing optimal performance over time and maximum operational safety. This approach significantly prevents damage caused by poor quality parts - which could fail under the stress of site operations - and drastically reduces downtime. Unplanned downtime can lead to significant project delays and financial losses.

Maintaining the reliability of your equipment is crucial for site productivity. Therefore, choosing original spare parts is a decision that pays off in the long run.

4 - Not planning maintenance according to use

Not planning maintenance correctly according to the use of the machinery can lead to too frequent or insufficient interventions.

Elsa suggests intelligent maintenance planning that takes into account the intensity and specific conditions of use of each machine. Thanks to the versatility of our Supercombinata Line Boring Machines, we ensure the success of dynamic maintenance strategies, optimising on-site interventions.

This approach ensures that your machinery is always in perfect working condition, minimising unscheduled downtime and avoiding waste of time or resources.

Optimising maintenance for greater efficiency and safety

In summary, avoiding the 4 most common mistakes in machinery maintenance is crucial to ensure:

- efficiency;

- safety;

- long-term profitability.

Ignoring preventive maintenance, neglecting diagnostics, using non-original spare parts and not planning interventions correctly can generate unexpected costs and stop production.

Elsa's innovative multifunctional portable boring machines, the leader in portable machine tools, offer the ideal tools to overcome these challenges.

Investing in Elsa's quality and technology means:

- Ensuring maximum operational efficiency of your machinery;

- Extending the service life of your heavy equipment;

- Reducing downtime and optimising productivity;

- Ensuring operational safety and reliability at every stage of the process.