The oil industry faces complex technical challenges. Find out why Elsa portable line boring machines are the ideal choice for on-site maintenance.

The oil industry is among the most demanding and tough in terms of performance, safety and operational reliability. Offshore installations, refineries, pipelines and terminals are subject to constant wear, corrosion, mechanical stress and extreme environments. In this scenario, every hour of plant downtime has a significant economic impact and every technical error can turn into a safety or environmental problem.

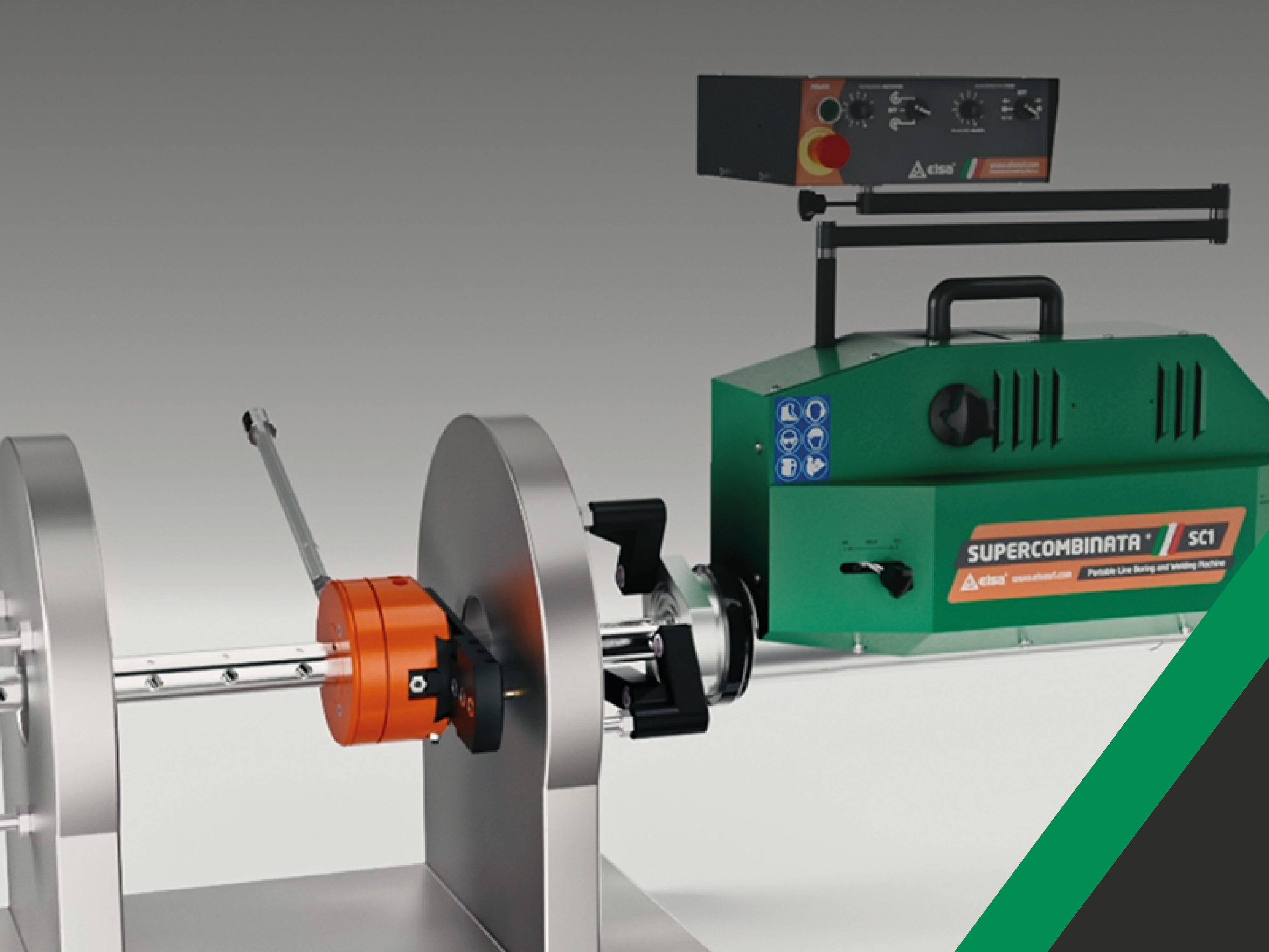

Precisely for these reasons, predictive and corrective maintenance plays a fundamental role, but it can no longer be based on slow or invasive techniques. This is where Elsa's Supercombinata portable line boring machines come into play, machine tools designed to intervene directly in the field, with centesimal precision and reduced times.

Working in the oil industry: technical and operational challenges

Drilling rigs, offshore platforms and refineries require maximum operational availability. However, the complexity of the installations and the often hostile environment expose many critical components to premature deterioration.

Common problems include:

- Wear of mechanical seats of pins, mountings and joints;

- Deformation and out-of-roundness due to vibration and cyclic loads;

- Corrosion of flanges and sealing surfaces, particularly in coastal or marine areas;

- Need for frequent reworking and grinding to maintain full functionality of components;

- Prolonged downtime for disassembly and transport of large components to the workshop.

Tackling these problems with traditional methods means inefficient use of time and increased costs, thus putting business continuity at risk. The industry therefore needs mobile, flexible and precise solutions, capable of operating directly on the equipment, even in confined spaces or difficult environments.

Supercombinata Elsa: the right answer for the oil & gas sector

Elsa, with over 25 years of experience in the development of portable line boring machines, offers a range of solutions designed for the oil & gas world. The Supercombinata series consists of multifunctional machine tools capable of performing a wide range of on-site machining operations with extreme precision and reliability.

The main operations that can be performed:

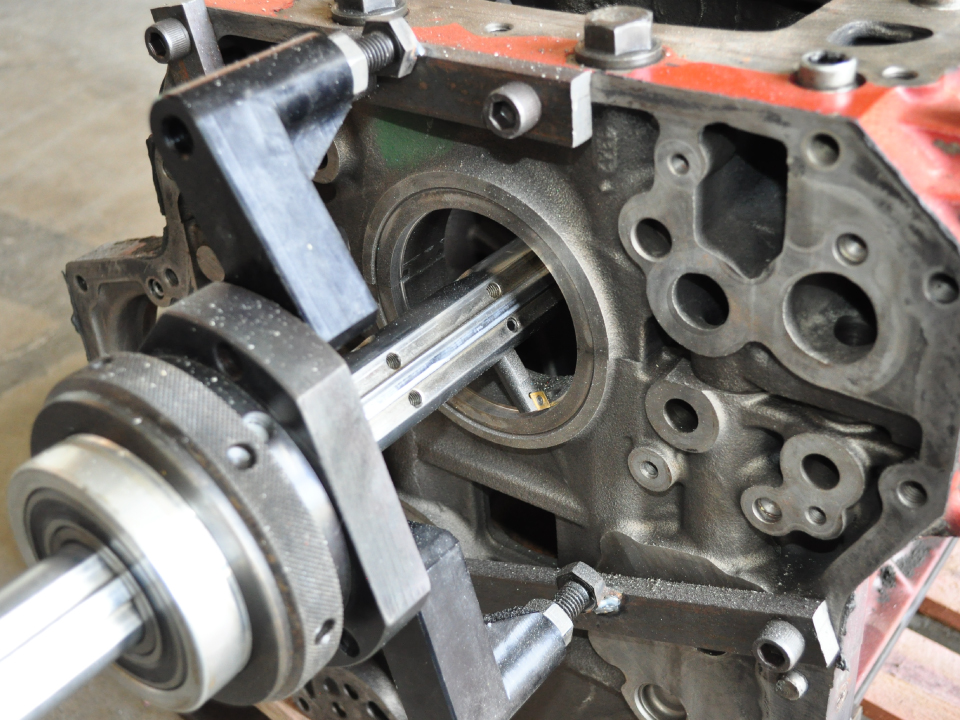

- Line boring: for regenerating damaged, worn or deformed holes, such as bearing housings or structural pin seats.

- Flange turning and flange facing: to restore critical coupling surfaces, preventing leakage and improving sealing.

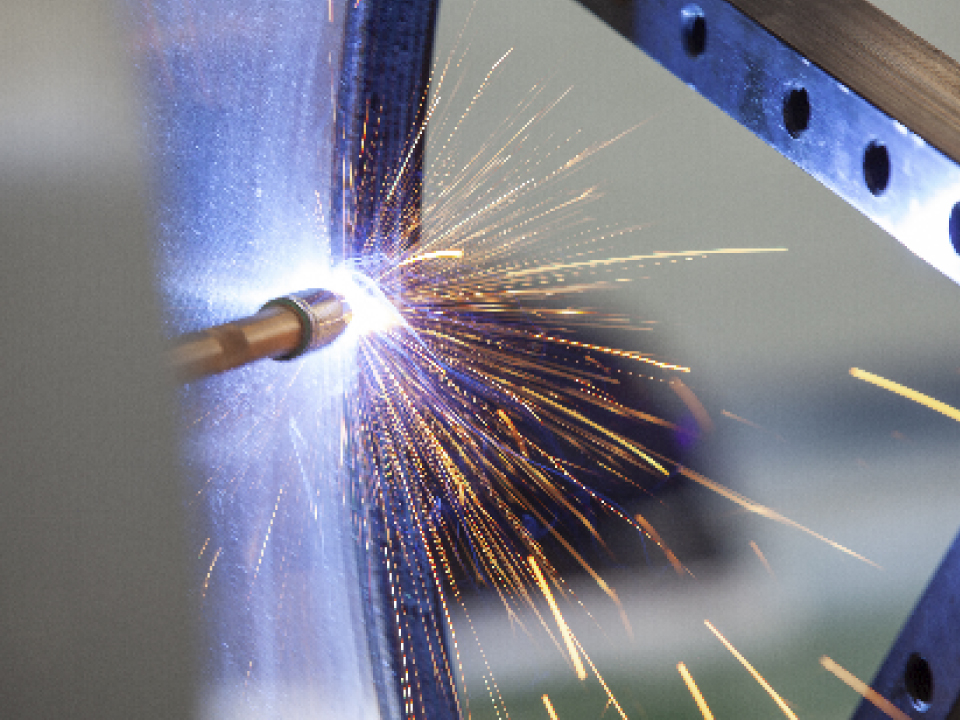

- Welding: to rebuild removed or corroded material.

- Coupling machining: to maintain coaxiality between several distant seats (such as on valves, manifolds or pumping systems).

- Bushing seat fabrication: useful when revamping or adapting components.

Concrete advantages for the oil & gas industry

Choosing an Elsa Supercombinata machine for maintenance in the oil industry means accessing a series of immediate advantages:

- Drastic reduction of plant downtime: operating directly on site, disassembly and transport are avoided, saving time and resources.

- Guaranteed precision: each machine is equipped with centesimal adjustments, guaranteeing tight tolerances even in non-ideal conditions.

- Extreme versatility: the same machine allows machining on bores from 22 mm up to 1700 mm, thus adapting to all plant requirements.

- Compactness and manoeuvrability: the compact design allows operation even in cramped environments or on offshore platforms.

- Reliability even in hostile environments: robust materials, mechanical protection and industrial design ensure durability and performance over time.

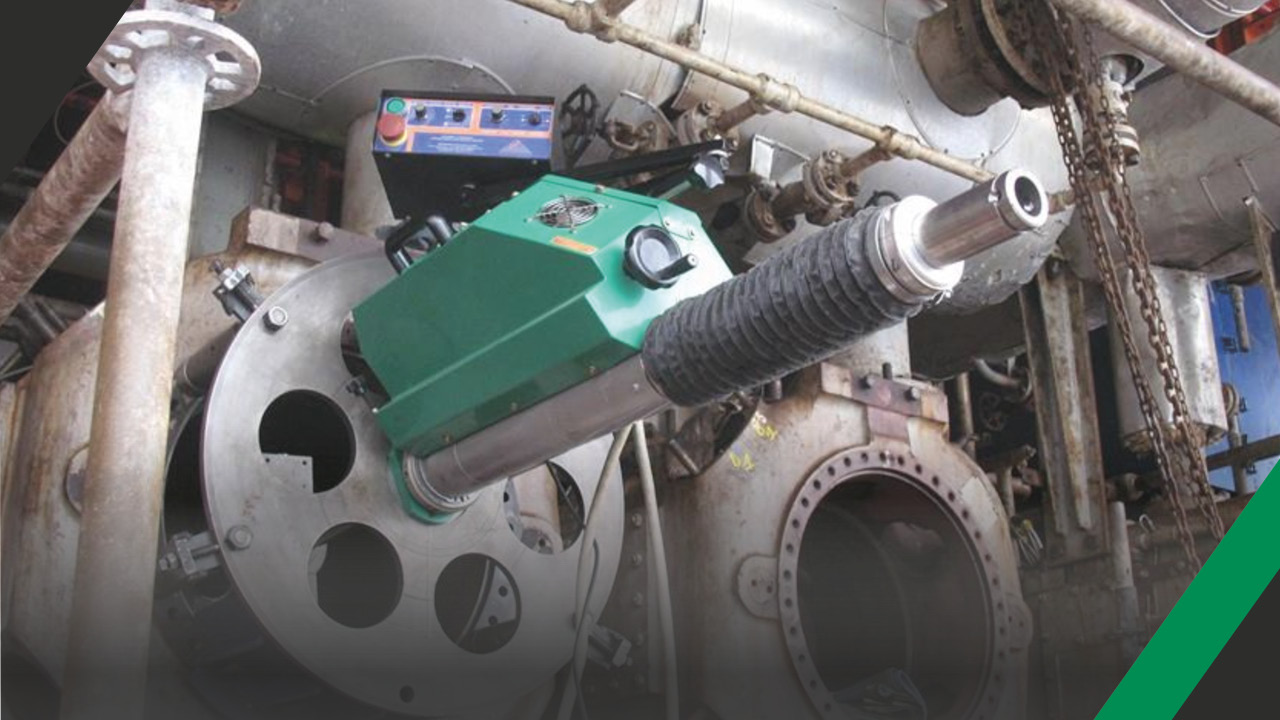

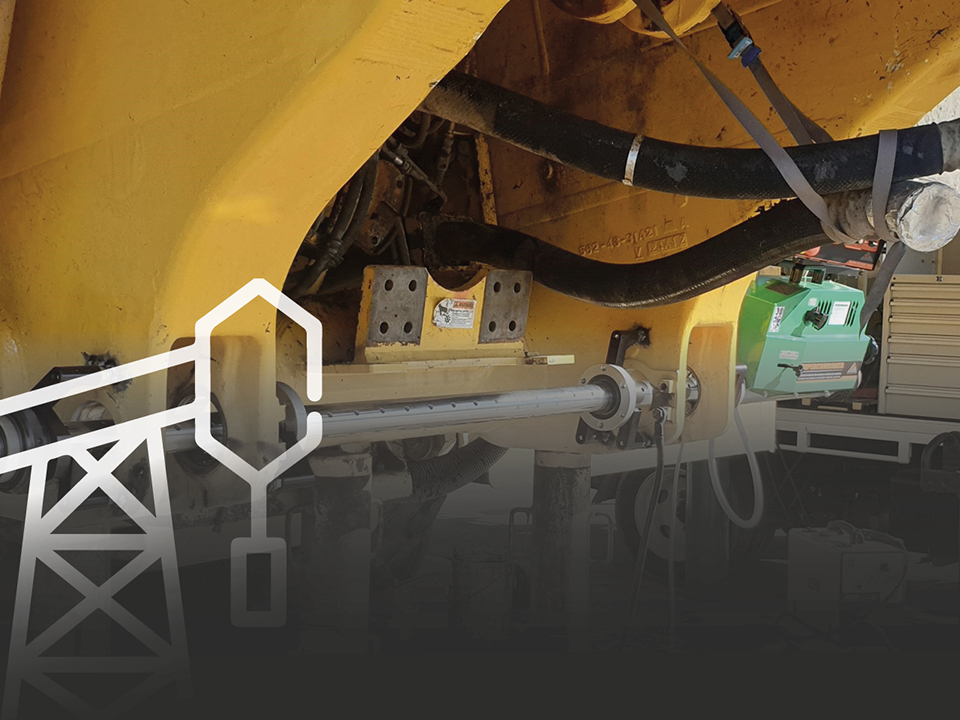

Use cases: the Supercombinata at work

Supercombinata line boring machines are already in use in numerous onshore and offshore oil rigs around the world. Some of the actual applications include:

- Valve seat reaming on high-pressure pipelines;

- Line boring of pump supports in refineries;

- Facing of flanges damaged by marine corrosion on offshore platforms;

- Machining of bearing structures and mechanical arms on drilling rigs and towers;

- Repair of motor bases and alignments on compressor units.

Each operation is carried out with the machine directly on site, often within a few hours, completely eliminating the need for lifting, transport or dismantling.

Why Elsa is the ideal partner

Elsa offers not just machines, but complete solutions designed for mechanical maintenance professionals. Thanks to a global network and a constantly active in-house technical department, the company supports each customer with:

- Customised training and detailed technical manuals;

- Fast and competent pre- and after-sales support;

- Always available spare parts and continuous upgrades.

Every Supercombinata is designed, assembled and tested in Italy, in full compliance with the highest industry standards.

Conclusion: a strategic investment for every plant

In the oil industry, where maintenance cannot afford delays or inaccuracies, Elsa's Supercombinata portable line boring machines are a strategic ally. Thanks to the ability to intervene directly on site, with speed and reliability, these solutions make it possible to reduce downtime, increase efficiency and keep plants operational at all times.