In the nuclear sector, maintenance cannot afford any mistakes. Elsa’s portable line boring machines guarantee fast, certified on-site machining. The nuclear energy supply chain is one of the most regulated, complex, and sensitive in the global industrial landscape. Every facility, whether it is an active reactor, a plant undergoing decommissioning, or a research laboratory, requires high-precision mechanical maintenance, traceability of operations, and compliance with strict safety protocols.

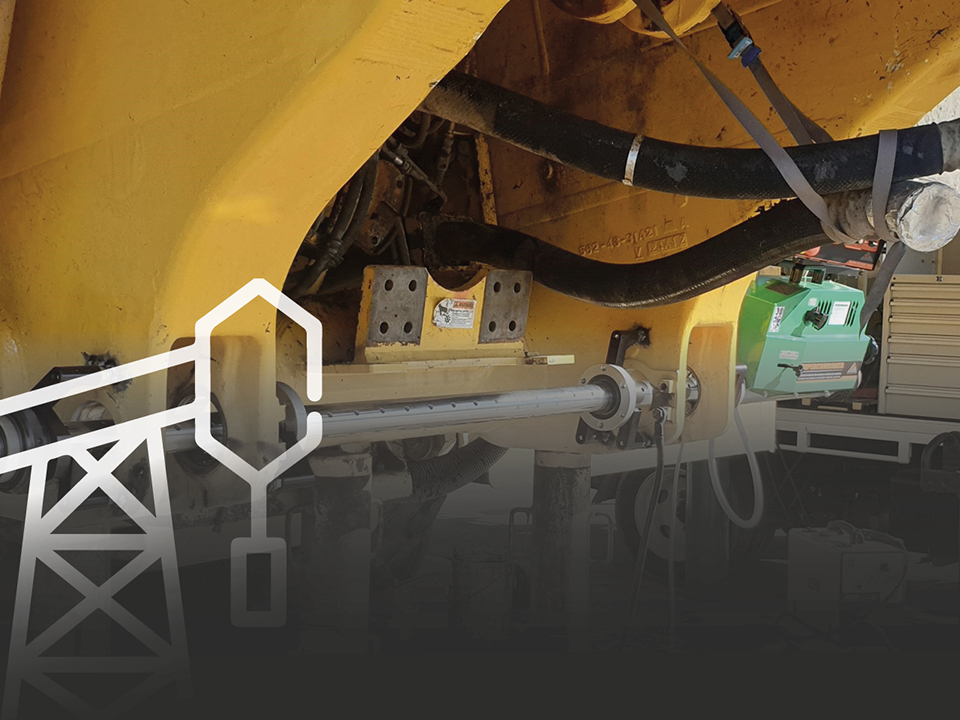

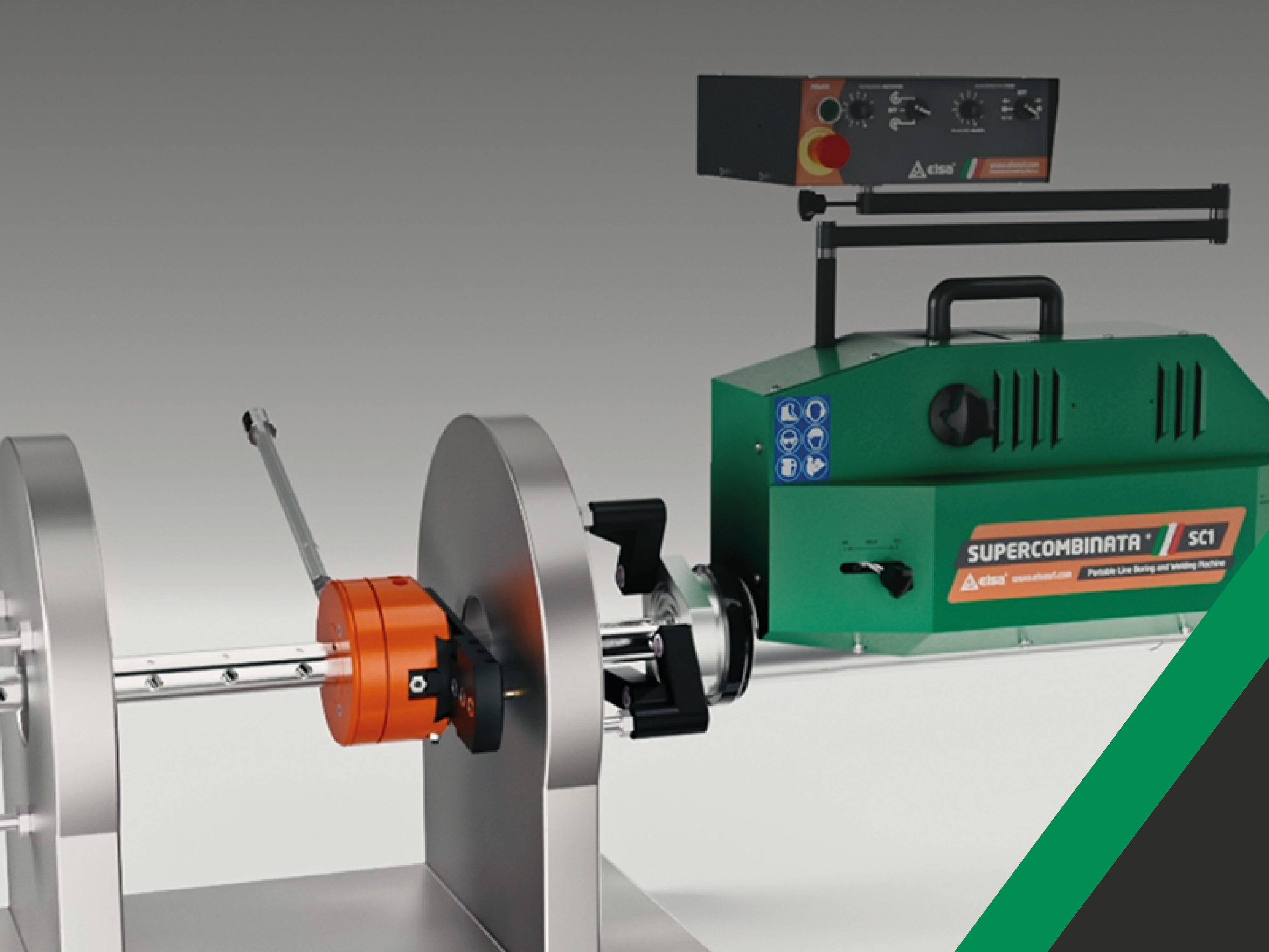

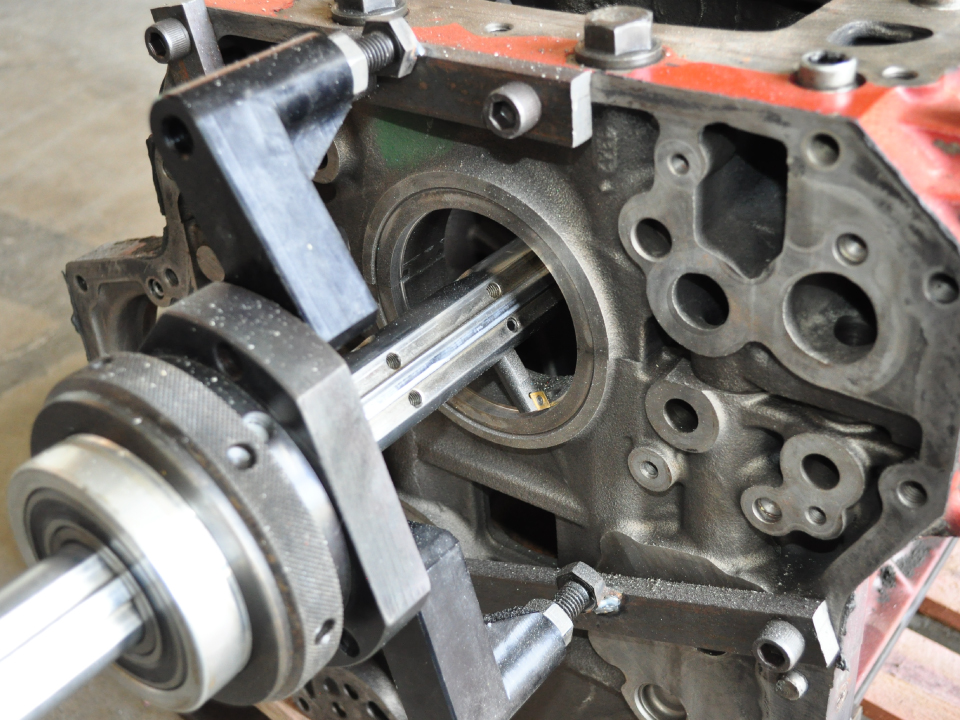

In this field, Elsa's Supercombinata portable line boring machines are reliable, versatile technical tools designed to work directly on site.

Working in a nuclear power plant: more than just a technical challenge

Maintenance in the nuclear sector presents a series of unique constraints compared to other industrial sectors:

-

Operating areas may be highly radiation-protected, shielded, or confined spaces.

-

Transporting components outside the facility is often prohibited or severely restricted by regulations.

-

Mechanical tolerances must be strictly adhered to in order to prevent leaks, vibrations, or functional alterations.

-

Access times and methods are governed by strict internal procedures, which do not allow for delays or unexpected changes.

In many cases, even an apparently simple machining operation, such as grinding a valve seat, requires detailed planning, certifiable technical documentation and a reliable, precise and flexible machine tool.

Elsa has the answer: a multifunction portable line boring machine

Elsa's Supercombinata series is designed to offer total flexibility and safety, even in tricky nuclear settings. Each model can handle mechanical maintenance and restoration work without taking apart any parts, which really cuts down on downtime and operational risks.

Among the most requested jobs:

-

Boring of damaged seats on valve bodies, pin housings or structural joints;

-

Flattening and grinding of sealing surfaces, such as flanges or engine bases;

-

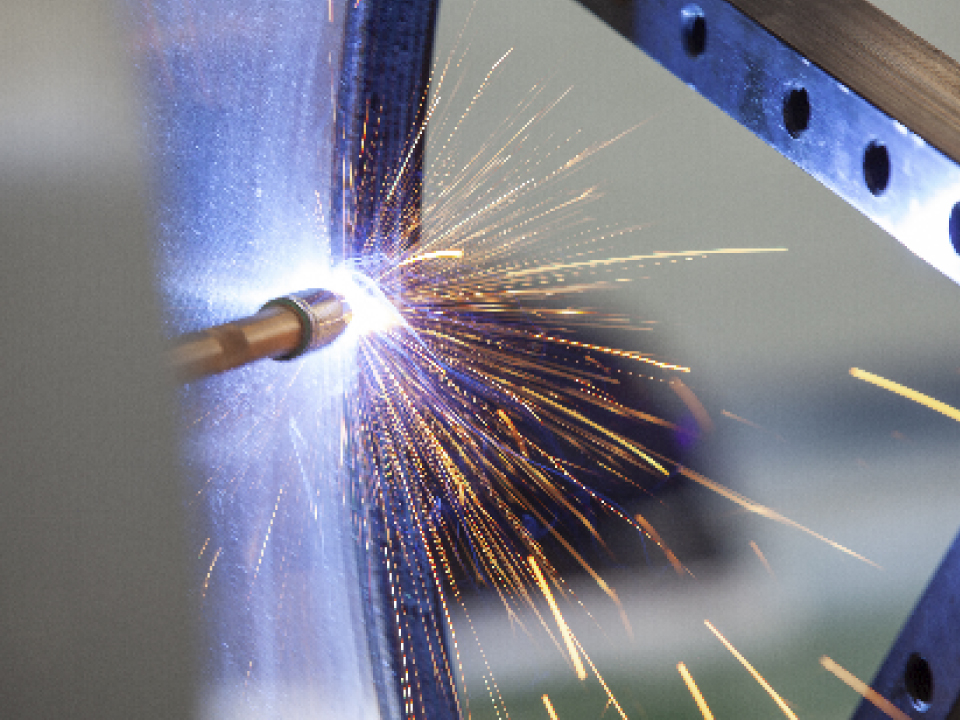

Controlled welding of overlays, followed by precision machining;

-

Geometric restoration of paired holes, maintaining coaxiality on rigid metal structures;

-

Preparation of seats for bushing insertion, in case of revamping or adaptation to new specifications.

Why on-site maintenance is the real revolution for nuclear power

Using an Elsa portable boring machine in a nuclear environment means drastically simplifying complex processes. The real advantages include:

-

There's no need to transport valves, pumps, or supports. The work is done right in the authorised area.

-

It's super precise: thanks to centring and micrometric adjustment systems, the tolerances required by the industry are met without any compromises.

-

It saves time: faster work means less exposure, lower costs, and less impact on plant authorisations.

-

Adaptability to small spaces: the compact and modular design allows for use even in closed environments or those with limited access.

Areas of application: from production to dismantling

Supercombinata portable boring machines are used along the entire nuclear supply chain, in particular for:

-

Active power plants (PWR, BWR, fast reactors);

-

Scientific research facilities and university laboratories;

-

Radioactive waste treatment and conditioning centres;

-

Medical isotope production facilities;

-

Nuclear decommissioning sites.

In any situation, the opportunity to operate quickly, safely, and with extreme precision represents an irreplaceable added value.

Elsa's experience

Elsa does not just supply a product, but offers a complete solution, built on the real needs of technicians, maintenance engineers and plant managers. With over 25 years of experience in highly critical industrial applications, Elsa is now a recognised partner for precision mechanical maintenance.

What we guarantee:

-

Made in Italy design, with industrial quality standards;

-

On-site technical assistance and training, even in radiation-protected environments;

-

Multifunctional portable machines, with detailed technical documentation;

-

Efficiency and availability, thanks to a global commercial and technical network.

Why choose Elsa

In the nuclear field, every machining operation is closely linked to reliability, control and safety. Choosing Elsa's Supercombinata portable boring machines means investing in a technologically robust, precise and certifiable solution that can operate even in the most regulated environments in the world.