The wind power sector requires fast and precise mechanical interventions at high altitudes. Elsa's mobile line boring machines work directly on the turbine.

Wind power sector and mechanical maintenance: why this is of fundamental importance

Wind energy is a cornerstone of the global energy transition and guarantees a clean and sustainable energy source.

Wind turbines require constant and expert maintenance, especially for components that are subject to high mechanical stress:

-

Hubs

-

Pitch/yaw alignment systems

-

Generator mounts

-

Blade mounts

Maintenance challenges in the wind power sector

- Working at height: operations often carried out at heights of tens of metres.

- Large components that make dismantling and transport difficult.

- Limited space and tight deadlines for completing repair work.

The main mechanical problems in the wind power sector

The rotors and mechanical systems of wind turbines are exposed to constant dynamic loads, vibrations and temperature variations which, over time, cause:

- Wear of the pin seats in the blade orientation system (pitch);

- Ovalisation of holes in the drive shaft or gearbox supports;

- Corrosion and damage to the connection flanges at the tower, hub and generator;

- Mechanical play that compromises efficiency and increases vibrations;

- Interventions that are difficult to plan, especially in offshore farms or isolated areas.

With traditional methods, reworking a damaged seat requires removing the entire component and taking it to a workshop, resulting in high costs, the use of cranes and long downtimes.

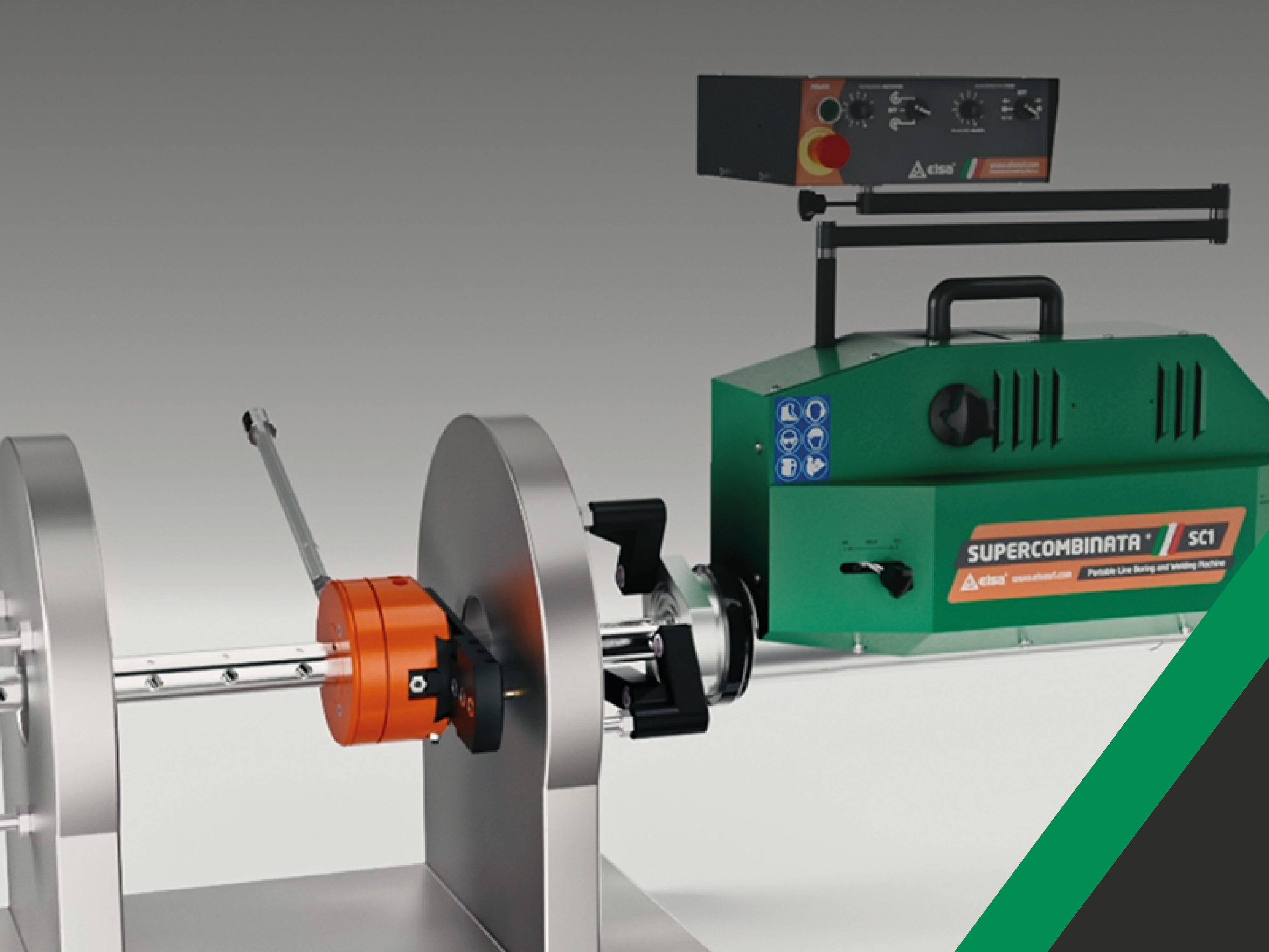

Elsa Supercombinata: the solution for wind turbine maintenance at height

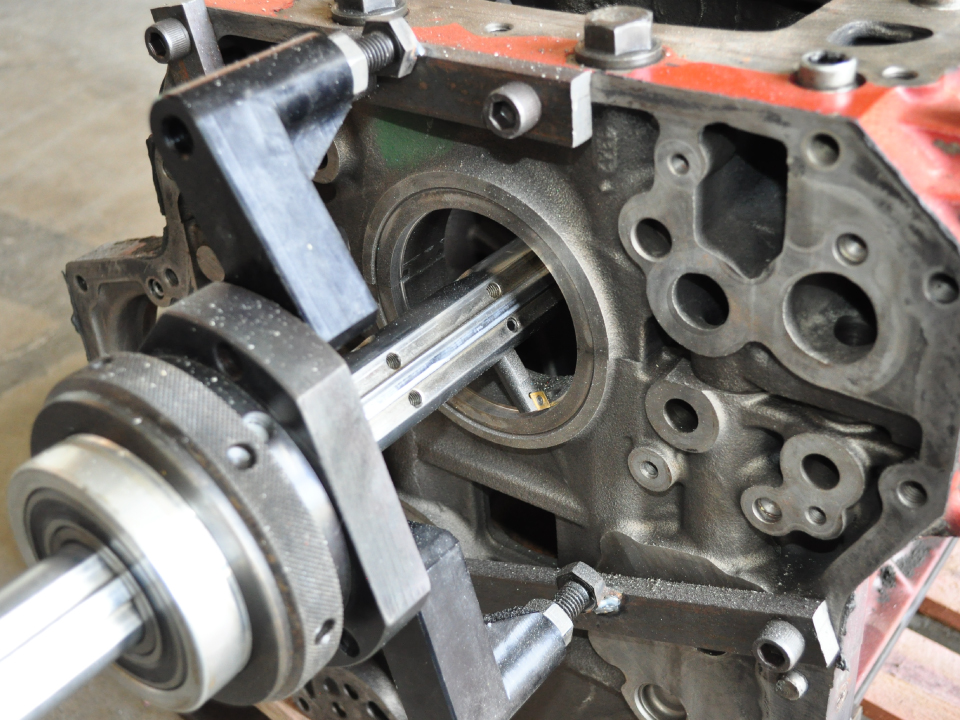

Supercombinata portable line boring machines have been designed specifically to overcome these limitations. They are portable, multifunctional, high-precision machine tools that allow machining to be carried out directly at the installation site.

With an Elsa Supercombinata, you can perform:

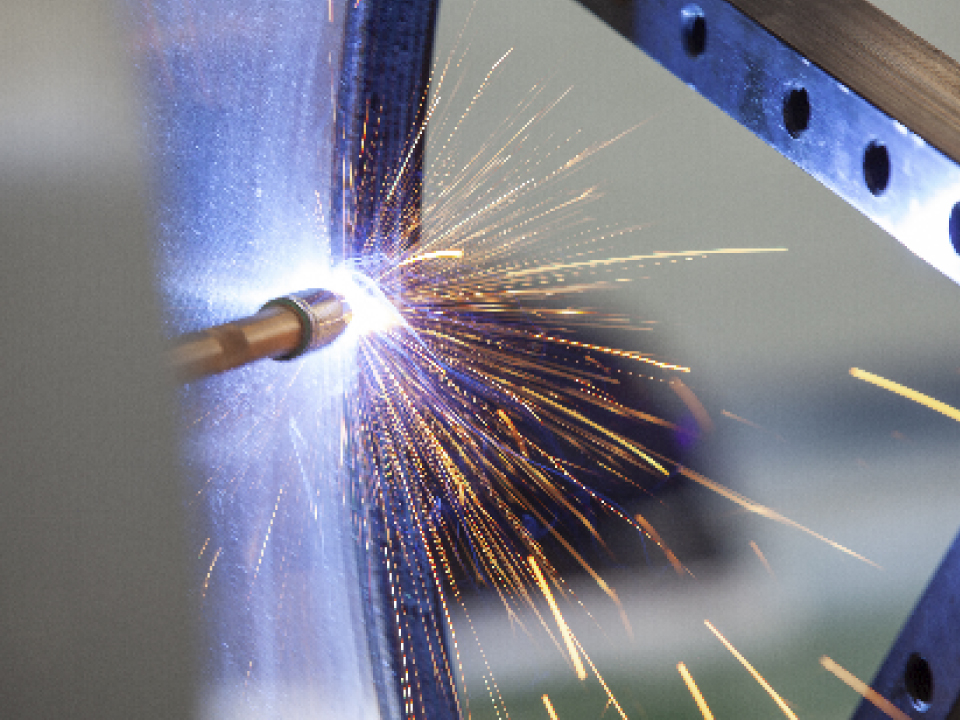

- Line Boring of damaged or ovalised seats in hubs, joints or blade pitch adjustment systems;

- Flattening of coupling surfaces, such as flanges between the tower and nacelle or between the hub and multiplier;

- Welding repair, followed by new machining at height;

- Preparation of seats for bushings, useful during regeneration work.

The machine is easily transported inside the tower, even with technical lifts or hoists. Once at height, it can be mounted directly on the component to be machined and operate with maximum precision and speed, even in less than ideal weather conditions.

Concrete advantages for the wind power sector

The use of Supercombinata line boring machines in wind power plants brings immediate benefits for both operators and plant owners:

- Machining directly on site, without dismantling or transporting components;

- Drastic reduction in turbine downtime, with rapid return to production;

- Guaranteed precision, even on large holes;

- Adaptability to confined spaces and complex environments, such as nacelles (gondolas);

- Better management of scheduled maintenance, with less dependence on external workshops;

- Significant cost savings on logistics, transport, machine downtime and labour.

Practical applications in the wind power sector

Elsa portable line boring machines are already in use in numerous onshore and offshore wind farms, where they are used to:

- Bore out blade pivot seats damaged by wear or excessive play;

- Restore alignment between the shaft support and generator, which is essential for reducing vibration and friction;

- Smoothing out deformed or corroded flanges to ensure structural integrity and safety;

- Regenerating yaw systems, the systems that orient the nacelles in the direction of the wind, which are subject to cyclic mechanical stress.

Each intervention can be scheduled quickly and completed in a few hours, reducing the risk of prolonged and costly downtime.

Why choose Elsa for wind turbine maintenance

Elsa is a benchmark in the design of professional portable line boring machines. Each machine is entirely designed and manufactured in Italy, according to high industrial standards and with know-how gained from over 25 years of experience in the field.

With Elsa, you get:

- Robust, compact and versatile technology, perfect for high-altitude applications;

- Personalised technical training, including on-site;

- Direct pre- and post-sales support, with worldwide assistance;

- Specific accessories and kits, ready to use.

Conclusion: the right solution for every turbine

In the wind power sector, maintenance at height must be fast, accurate and reliable. Elsa's Supercombinata portable boring machines are the ideal tool for any mechanical work directly on the turbine. No cranes, no transport to the workshop: just efficiency, precision and operational continuity.

Contact us today to find out which model best suits the needs of your wind park.